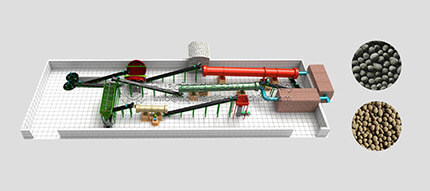

Organic fertilizer production line processing green organic fertilizer enhances agriculture

Organic fertilizer production line processing green organic fertilizer enhances agriculture

Application of traditional organic fertilizer Application of traditional organic fertilizer has a long history. Up to now, it is still the main method of applying base fertilizer in autumn and winter in most orchards. The common methods in production are compost, chicken manure, cow manure, pig manure, sheep manure and other animal manure and human manure. Among them, sheep dung is a natural green fertilizer, containing 4%~27% organic matter, more than other animal dung, rich in nitrogen, phosphorus and potassium nutrition, fine dung and thick fertilizer, belonging to thermal fertilizer. Chicken dung contains rich nutrients, especially the crude protein in chicken dung. The content of organic matter reaches 25.5%. Through proper processing and utilization of organic fertilizer production line, it can become a better green organic fertilizer.

Enhance crop resistance to disease, drought and waterlogging

Organic fertilizer contains vitamins and antibiotics, which can enhance crop resistance and reduce or prevent disease. After applying organic fertilizer into the soil, it can enhance the water storage and water retention capacity of the soil, and enhance the drought-resistant capacity of crops under drought conditions.

At the same time, the organic fertilizer processed by the organic fertilizer production line can also make the soil loose, improve the ecological environment of crop roots, promote the growth of roots, enhance root vitality, improve the waterlogging tolerance of crops, reduce plant mortality, and improve the survival rate of agricultural products.

Improve the safety and greenness of food

The state has clearly stipulated that the excessive use of inorganic fertilizers must be restricted in the agricultural production process, and organic fertilizers are the main source of fertilizer for the production of green food.

Due to the complete variety of nutrient elements in organic fertilizers and the fact that these substances are non-toxic, harmless and pollution-free natural substances, this provides the necessary conditions for the production of high-yield, high-quality and pollution-free green food. Humic acid substances mentioned above can reduce the harm of heavy metal ions to plants, which is equivalent to reducing the harm of heavy metals to human body.

Increase crop yield

The beneficial microorganisms in the organic fertilizer processed by the organic fertilizer production line utilize the organic matter in the soil to produce secondary metabolites, which contain a large number of growth-promoting substances.

For example, auxin can promote the elongation and growth of plants, abscisic acid can promote the ripening of fruits, gibberellin can promote the flowering and fruit setting, increase the number of flowering and fruit preservation rate, improve the yield, make the fruit plump, fresh and tender in color, and can be listed early to increase production and income.

Reduce nutrient loss and improve fertilizer utilization

The actual utilization rate of fertilizer is only 30%~45%. Some of the lost fertilizer is decomposed and released into the atmosphere, some is lost with the water and soil flow, and some is fixed in the soil and cannot be directly absorbed by plants.

When organic fertilizer is applied, the beneficial biological activities improve the soil structure, increase the soil water and fertilizer retention capacity, and reduce the loss of nutrients. In addition, the effective utilization rate of fertilizer can be increased to more than 50% by the effect of phosphorus and potassium hydrolysis by beneficial microorganisms.

To sum up, the benefits of organic fertilizer processed by organic fertilizer production line to agriculture illustrate its advantages. With the improvement of people’s pursuit of food safety and quality of life, the development of green agriculture will accelerate the application of organic fertilizer in the future, and also truly meet the requirements of sustainable development of modern agriculture.