The working principle and raw materials of the disc granulator for compound fertilizers

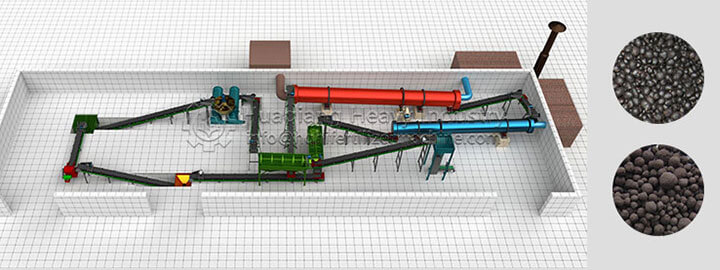

The disc granulator for compound fertilizers is a type of traditional granulation equipment, which has the advantages of uniform granulation, high granulation rate, stable operation, sturdy and durable equipment, and long service life. It is a granulation equipment for producing organic fertilizers, compound fertilizers, metallurgy, coal powder, cement, limestone, coal gangue and other materials.

The compound fertilizer disc granulator is suitable for granulating organic fertilizer, compound fertilizer, compound fertilizer, and organic-inorganic compound fertilizer:

Working principle of the disc granulator for compound fertilizers:

Disk granulation is face-to-face, easy to control, and flexible to adjust. Install a water spray device above the disc to spray it out in a mist shape. The material continuously flows into the rotating disc through a belt conveyor or other conveying equipment, and is carried up as the disc rotates. Then it falls along the bottom of the disc to the bottom, and due to the addition of mist like moisture, the material gradually forms particles during the process of rotating and falling with the disc. As time goes on, the particles gradually increase. The compound fertilizer disc granulator is designed with an angle adjustment mechanism, and users can determine the inclination angle of the disc according to the required particle size. Generally, the inclination angle of the disc can be adjusted between 35 ° and 50 °, and particles that meet the specifications float above the inclined disc. As the disc rotates, the particles are thrown out along the tangential direction of the disc and pulled into the next ring in the feeding port of the belt conveyor.

The compound fertilizer disc granulator can be used to transport various non cohesive materials in powder, material or small pieces, such as coal powder, cement, clinker, limestone, shale, coal gangue, clay and other powder, particle or small pieces of materials. It can be widely used in gold selection plants, coal mining plants, chemical engineering, infrastructure and mechanized casting workshops for continuous, uniform and quantitative feeding and batching.

.jpg)

.jpg)