Organic Fertilizer Equipment Made from Chicken Manure to Solve Pollution in Livestock and Poultry Farms

Chicken manure organic fertilizer equipment can effectively solve the environmental pollution caused by organic waste in industries such as livestock and poultry breeding, reduce the eutrophication of surface water caused by pollution, improve the safety and quality of agricultural products, and lay a good foundation for human comprehensive consumption of green and organic food. The ecological and environmental benefits are extremely significant..jpg)

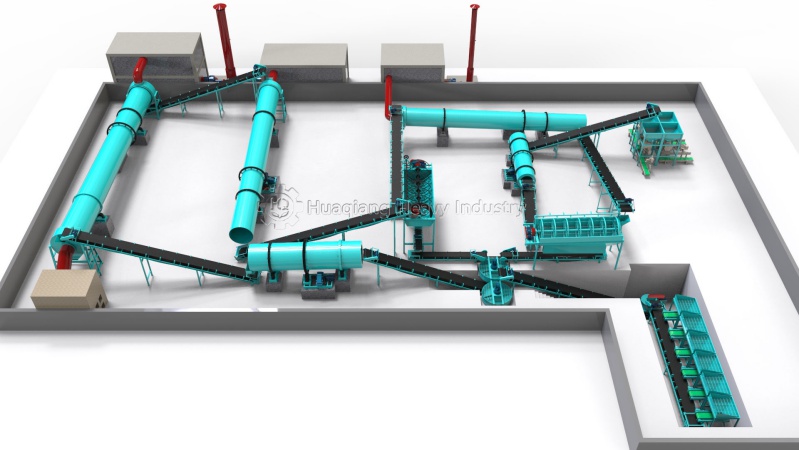

1. The fermentation system of the chicken manure organic fertilizer production equipment process consists of a feed conveyor, a biological deodorizer, a mixing mixer, a proprietary lifting and tilting machine, and an electrical automatic control system;

2. The main equipment of the drying system for chicken manure organic fertilizer production equipment includes belt conveyor, rotary dryer, cooler, induced draft fan, hot air stove, etc;

3. The deodorization and dust removal system of chicken manure organic fertilizer equipment consists of a settling chamber, a dust removal chamber, and other components. It includes a new type of semi wet material crusher, LP chain crusher or cage crusher, and a belt conveyor;

4. The ingredient system of chicken manure organic fertilizer equipment includes electronic ingredient system, disc feeder, vibrating screen, and can be configured with 6-8 types of raw materials at one time;

5. The mixing system of chicken manure organic fertilizer equipment consists of optional horizontal or disc mixers, vibrating screens, mobile belt conveyors, etc;

6. The granulation system for the process flow of chicken manure organic fertilizer equipment requires the use of granulation machine equipment. The optional granulation machine equipment includes: composite fertilizer roller extrusion granulation machine, disc granulation machine, flat film granulation machine, biological organic fertilizer spherical granulation machine, organic fertilizer specialized granulation machine, drum granulation machine, round throwing machine, composite fertilizer specialized granulation machine, etc;

7. The cooling and drying system of chicken manure organic fertilizer equipment can be used to dry and cool equipment such as rotary dryers and drum coolers. The screening system is mainly completed by drum screening machines, which can be equipped with primary and secondary screening machines to achieve higher yield and better particles;

8. The finished product packaging system of chicken manure organic fertilizer equipment generally includes electronic quantitative packaging scales, silos, automatic sewing machines, etc. This can achieve fully automatic and uninterrupted production of chicken manure organic fertilizer production line.

.jpg)

.jpg)

.jpg)