Advantages of Multiple Silos Single Weigh Static Batching System

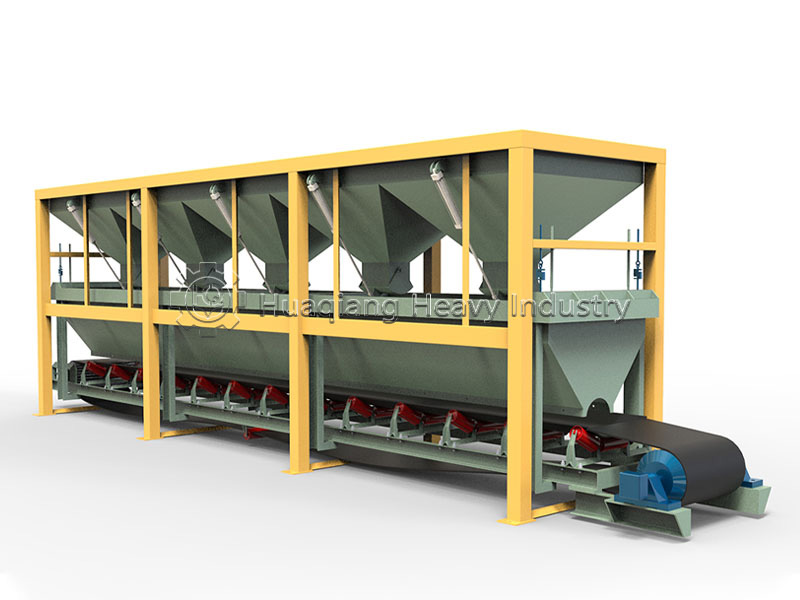

System Overview

The multiple silos single weigh static automatic batching system is a highly integrated automated material processing equipment widely used in industries such as chemical, pharmaceutical, food, and plastic processing. This system can simultaneously process multiple different materials, accurately measuring them through an independent weighing system to ensure mixing according to preset proportions, meeting the strict requirements for material ratios in the production process.

Workflow

After system startup, materials are transported from their respective independent silos to corresponding weighing units through the conveying system. Electronic scales precisely measure the weight of each material, and when preset values are reached, the system automatically stops material transportation. Subsequently, all weighed materials are sent to the central mixer for mixing to ensure uniform material distribution. After mixing is completed, the finished product is conveyed to the next production stage.

Core Advantages

High Precision Batching

Independent weighing units ensure each material is added in precise proportions, improving product quality consistency and stability. Each material silo is equipped with high-precision electronic scales, avoiding measurement errors in traditional batching systems.

High Automation

Automated control of material conveying, weighing, and mixing processes reduces manual operations and improves production efficiency. PLC or industrial computer control systems ensure coordinated operation of the entire process.

Flexibility and Adaptability

Capable of handling various types and characteristics of materials, including solids, liquids, and viscous materials, suitable for various production formulas. Multiple material silo design meets diverse production needs.

Efficient Production

Multiple material silos and weighing units work in parallel, reducing batching time and increasing production line throughput. Continuous production mode ensures uninterrupted production processes.

Safety and Environmental Protection

Comprehensive safety protection systems and enclosed design reduce operational risks and environmental pollution. Overload protection, emergency stop buttons, and material detection sensors ensure safe equipment operation.

Application Value

Through its precise measurement capabilities, efficient automation level, and flexible adaptability, the multiple silos single weigh static batching system provides reliable batching solutions for modern industrial production. This system not only improves product quality stability but also significantly enhances production efficiency, while reducing labor costs and material waste, making it an ideal choice for achieving intelligent production.

Integrated Automation in Modern Fertilizer Manufacturing

The precision batching system serves as the critical foundation for modern fertilizer production lines, ensuring accurate nutrient ratios throughout various manufacturing processes. In the npk fertilizer production line, automated npk blending machine technology works in harmony with advanced granulation equipment to maintain formula consistency. Similarly, the organic fertilizer production line and bio organic fertilizer production line rely on precise material proportioning to achieve optimal fermentation conditions and final product quality.

Following precise batching, materials proceed through specialized fertilizer granulation processes utilizing equipment such as the disc granulator machine in disc granulation production line configurations, or the double roller press granulator in roller press granulator production line setups. These fertilizer granulator systems transform precisely batched materials into uniform granules, while complementary equipment like the windrow composting machine ensures proper organic matter preparation. The integration of automated batching with these advanced processing technologies creates a seamless production workflow that guarantees both nutritional accuracy and physical consistency in the final fertilizer products, supporting modern agriculture’s demand for reliable, high-quality inputs.

.jpg)