What equipment is essential in the production line of cow manure organic fertilizer

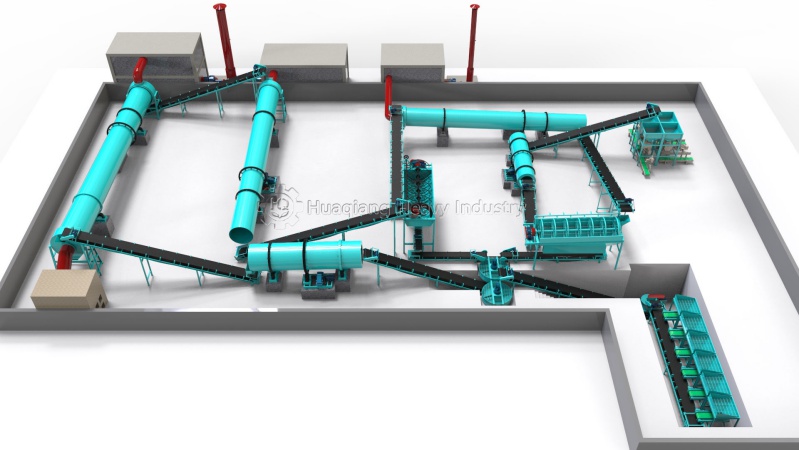

The production line of cow manure organic fertilizer involves multiple processes, from raw material pretreatment to final product packaging, each of which requires specialized equipment support. The following is a list of the main equipment necessary to build a complete cow manure organic fertilizer production line:.jpg)

1. Front end processing equipment

Collection and preliminary processing

Forklift/loader: used to collect fresh cow manure and transport it to the initial treatment area.

Screening machine: removes large debris such as plastic, stones, metal fragments, etc.

Fermentation preparation

Organic fertilizer grinder: Crush large pieces of cow manure and auxiliary materials (if applicable) to an appropriate size for better fermentation.

Organic fertilizer mixer: Mix cow manure with other organic materials such as straw, sawdust, rice husks, etc. to adjust the carbon nitrogen ratio and moisture content.

Fermentation treatment

Composting and turning machine: helps to ventilate cow manure during fermentation, maintain good oxygen supply, promote beneficial bacterial activity, and accelerate degradation.

Fermentation chamber/tunnel: provides a fermentation site, controls temperature and humidity, and ensures smooth anaerobic or aerobic fermentation.

Intermediate processing

dry

Organic fertilizer dryer: reduces the moisture content of fermented cow manure, making it easier to pelletize and store.

Organic fertilizer cooler: reduces particle temperature to prevent quality degradation caused by excessive heating.

Backend processing

Granulation

Organic fertilizer granulator (drum granulator, ring mold granulator, extrusion granulator, etc.): turns dried cow manure powder into granules of different specifications.

packing

Organic fertilizer screening machine: removes unqualified large particles or powders to ensure consistent product quality.

Organic fertilizer packaging machine: automatic weighing, filling, and sealing of organic fertilizer particles for easy sales and transportation.

Other auxiliary equipment

Deodorization system: processes harmful gases such as ammonia generated during fermentation to reduce environmental pollution.

Conveyor belt: connects various devices to ensure continuous and smooth operation of the production line.

Storage bin: Temporary storage of raw materials or finished products for batch management and logistics scheduling.

matters needing attention

The selection of each device should be based on specific production needs, material properties, production scale, and budget constraints. For example, large farms may require larger capacity and more efficient equipment, while small businesses may focus on cost-effectiveness and ease of operation. At the same time, environmental regulations are also an important factor that cannot be ignored, ensuring that the environmental standards of the production line meet the standards.

In addition, maintenance and upkeep are also key to the service life of equipment and the stability of the organic fertilizer production line. Regular inspections of equipment condition and timely replacement of vulnerable parts should be carried out to ensure the continuous and efficient operation of the production line.

.jpg)

.jpg)