How to Choose a Composting Turner: Windrow vs. Trough Systems – Which is Right for Your Organic Fertilizer Production?

In the process of converting livestock manure, crop residues, and other organic waste into high-quality organic fertilizer, aerobic fermentation is the core process. Choosing the right composting turner is a critical decision to ensure fermentation efficiency and control production costs. Currently, windrow composting turners and trough composting turners are two mainstream technological approaches, representing distinctly different production models and investment logics. Understanding their fundamental differences is the first step towards successful organic waste resource utilization.

Core Differences Explained: Open-Air Dynamic Fermentation vs. Workshop-Based Controlled Fermentation

Windrow composting turners are a classic example of open-air dynamic fermentation. They work by piling pre-treated materials into long, parallel windrows on a hardened surface. The turner (commonly self-propelled tracked or tractor-towed) travels along the windrows, using a high-speed rotating turning wheel to cut, scatter, mix, and move the material. This method has a relatively low investment threshold and is highly adaptable to different sites, especially suitable for processing bulky materials such as straw and garden waste. However, the fermentation process is completely exposed to the natural environment, significantly affected by rain, snow, and low temperatures, resulting in a longer fermentation cycle (25-45 days), and making odor and dust control more difficult.

Trough type composting turners represent the advanced direction of workshop-based controlled fermentation. Materials are placed in long concrete fermentation troughs, with a forced ventilation system at the bottom. The turner (usually rail-mounted) travels on tracks along the trough, using a height-adjustable turning drum to deeply turn, break up, and move the material backward. This fully enclosed or semi-enclosed design, combined with bottom aeration, creates an optimal environment for microbial activity. Its greatest advantage is extremely high fermentation efficiency, with the cycle shortened to 10-15 days, and it is virtually unaffected by weather, allowing for continuous production year-round. At the same time, the workshop environment facilitates the collection and treatment of exhaust gases, resulting in excellent environmental performance. Key Decision Dimensions: From Efficiency and Cost to Long-Term Planning

When considering these two types of equipment, you need to conduct a comprehensive evaluation from the following dimensions:

- Investment and Operating Costs

Windrow composting: Initial investment is mainly for equipment procurement and site hardening, resulting in less financial pressure. However, its operating costs, including manual labor (driving, covering), losses due to weather-related downtime, and potential environmental treatment costs, may account for a significant portion.

Trench composting: Requires a one-time investment in trench construction, plant buildings, and equipment, resulting in higher initial investment. However, its high degree of automation, reduced labor requirements, and improved turnover efficiency due to shorter fermentation cycles often make its comprehensive operating cost per ton of material more advantageous in large-scale production.

- Raw Material Processing Capacity and Site Requirements

Windrow composting: Offers high flexibility in processing capacity, allowing for easy expansion by increasing the length and number of windrows. However, it requires a large area of open-air hardened ground, and the material stacking height is limited (usually 1.5-2 meters).

Trench composting: The processing capacity per trench is clearly defined, and the scale can be expanded by increasing the number of trenches. It significantly saves land, employing three-dimensional deep-layer fermentation (depth can reach over 2.5 meters), and its processing capacity per unit area is several times that of windrow composting, making it ideal for projects with limited land resources.

Consider “organic waste resource utilization” as a long-term core business, and be willing to invest in higher efficiency, better environmental performance, and more stable products.

Choosing between windrow and trench composting is essentially a trade-off between initial investment flexibility and long-term operational efficiency, and a choice between adapting to nature and controlling the process. For investors determined to develop organic waste treatment into a modern, sustainable industry, the industrialized path represented by trench composting equipment is undoubtedly a solid foundation for building core competitiveness and coping with stricter environmental regulations in the future. We recommend that you make a strategic decision based on a clear self-positioning and detailed financial calculations that can support development for the next five to ten years.

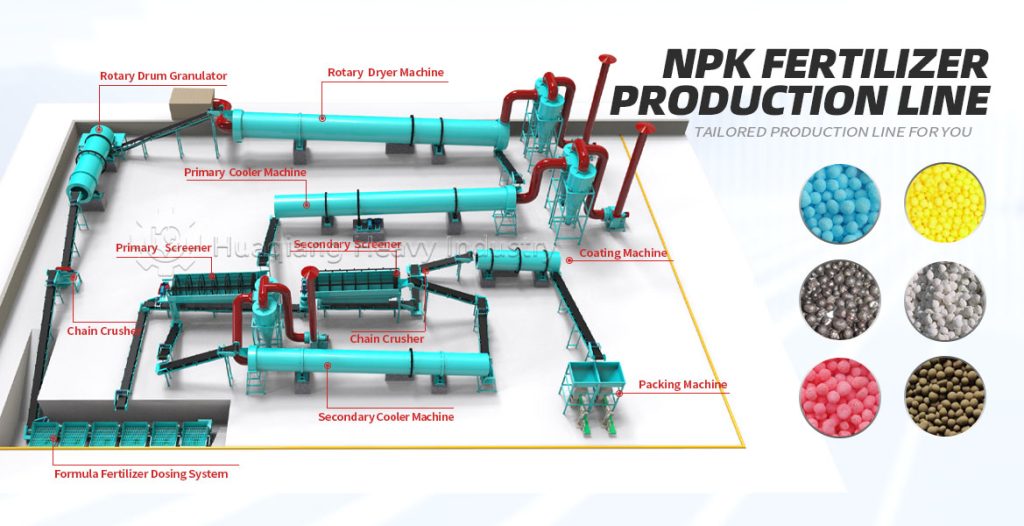

Complete System: From Raw Material Crushing to Efficient Composting

Regardless of the chosen fermentation method, the process begins with essential fertilizer raw material processing machinery and equipment. Before composting, materials like manure, straw, and crop residues require size reduction. A cage crusher is highly effective for softer materials, while a robust chain crusher handles harder, drier components. For materials with high moisture content (25%-55%), a specialized half-wet material crusher machine is essential to prevent clogging. Once properly prepared, these materials are ready for the fermentation composting turning technology stage. For open-air operations, a windrow composting machine serves as a versatile agriculture waste compost fermentation machine. For intensive, controlled production, trough-type aerobic fermentation composting technology is implemented using a trough-type compost turner, which ensures uniform aeration and rapid decomposition within a contained environment. The synergy between effective preprocessing and the correct fermentation equipment forms the foundation of a successful organic fertilizer production line.