The Heartbeat of Fertilizer Production

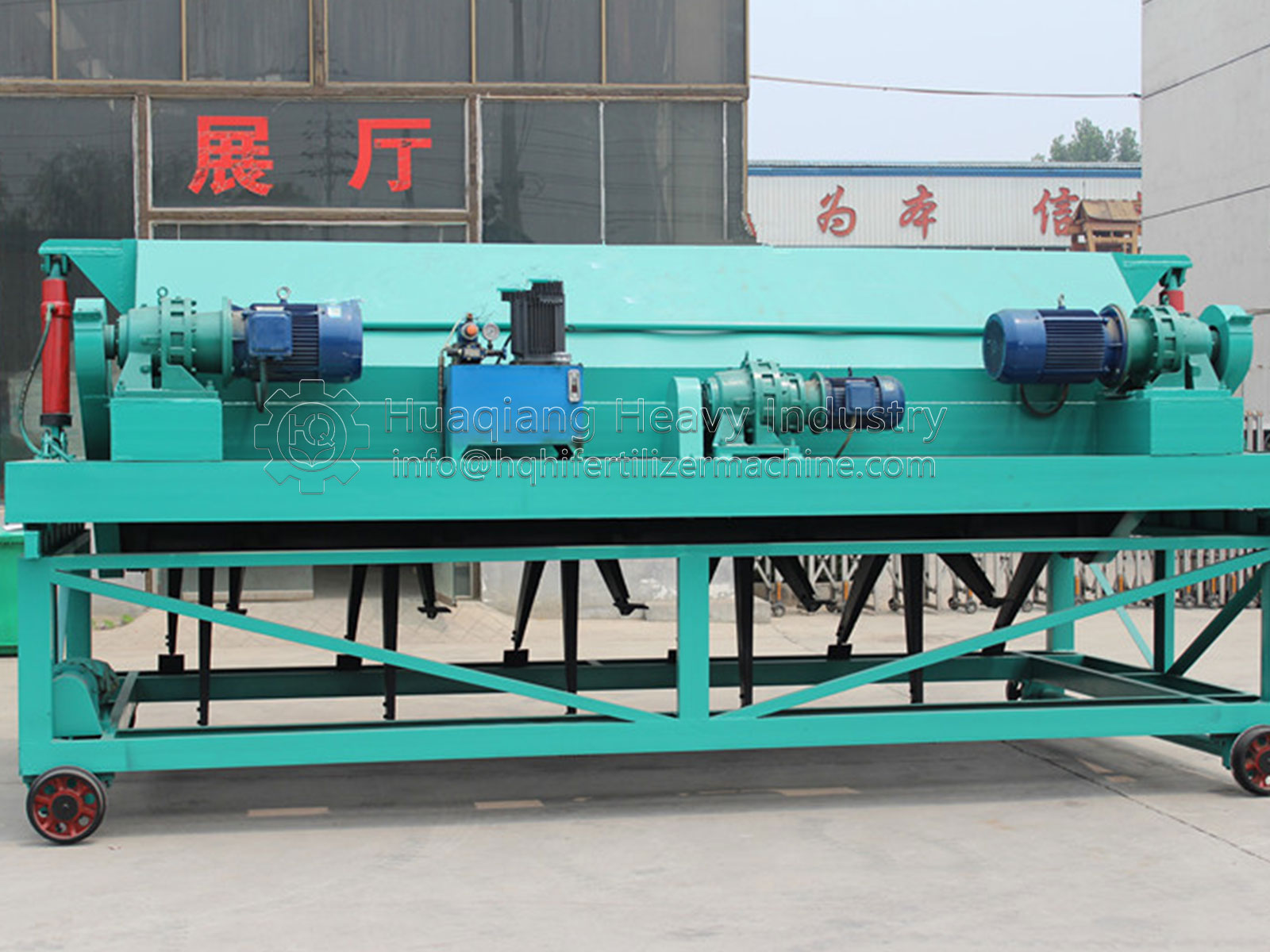

A windrow compost turning machine is a type of composting machinery specifically designed for aerobic fermentation of organic materials. It’s part of the equipment required for biofertilizer production, which typically includes a mixer, fermenter, grinder, and granulator. As a key component of fertilizer equipment, a windrow compost turning machine specializes in organic waste treatment, distinguishing itself from chemical fertilizer machinery in its focus on bio-organic material processing. Its crawler design provides stability and maneuverability for large-scale composting operations within a complete fertilizer production system.

The Central Nervous System

Imagine pretreated materials as ingredients waiting to be cooked, and the windrow compost turning machine as the chef mastering the heat. It precisely turns 2-meter-high organic windrows, much like a chef stir-frying dishes, ensuring every part gets even “heating.” This mechanical ballet can process thousands of tons daily, delivering perfectly fermented materials for subsequent granulation and drying processes.

The Metronome of Mass Production

In large fertilizer plants with annual outputs exceeding 50,000 tons, multiple windrows align like piano keys. The crawler turner moves like a skilled pianist, cycling through different zones following the composition of “fresh material loading – thermophilic fermentation – cooling maturation.” This “multi-zone rotation” enables 24/7 continuous production, transforming organic fertilizer making into true industrial assembly lines.

Did you know? Modern crawler turners’ intelligent control systems allow operators to adjust travel speed and turning frequency as precisely as a car’s accelerator via touchscreens. When downstream granulators speed up, the fermentation rhythm follows in real-time, ensuring the entire production line harmonizes like a symphony orchestra.

The Versatile Performer

Unlike fixed fermentation equipment, crawler turners can either coordinate seamlessly with other devices in modern plants or work solo in open fields. When farms need onsite manure treatment or cities must handle sudden garden waste, this steel giant can “relocate,” bringing production lines to materials rather than the opposite.

From farms to cities, windrow compost turning machines are redefining possibilities in organic fertilizer production. More than just bridges connecting pretreatment and refining processes, they’re alchemists transforming organic waste into black gold. In today’s sustainability-focused world, these flexible, efficient machines have become indispensable hearts of modern fertilizer production lines.