Cow dung is transformed into fertilizer for crops through biological fermentation technology. Fermentation compost turner machine speeds up the treatment process of compost fermentation technology, making cow dung fully fermented and qualified.

Fermentation composting

Aerobic composting is to absorb, oxidize and decompose wastes by aerobic bacteria under aerobic conditions. Through their own life activities, microorganisms oxidize part of the absorbed organic matter into simple inorganic matter, and release the energy needed for the growth of microorganisms, while the other part of the organic matter is synthesized into new cytoplasm, so that microorganisms continue to grow and reproduce, and produce more organisms. Under artificial control, under certain water content, C / N ratio and ventilation conditions, waste organic matter is transformed into fertilizer through microbial fermentation, which is called aerobic composting.

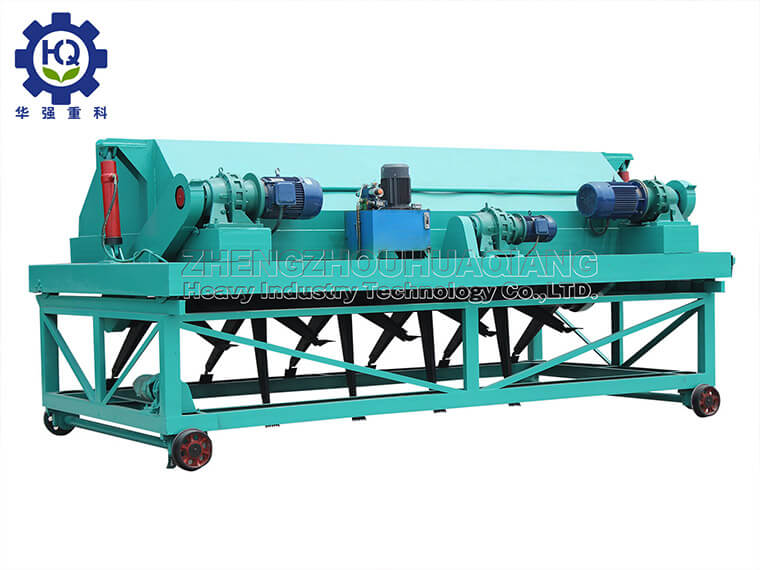

Turner machine handling cow manure compost

1. Advanced organic fertilizer production line uses microbial oxygen-consuming fermentation, which is planned according to the principle of oxygen-consuming fermentation, so that the fermenting bacteria have room to give full play to their functions.

2. The compost turner is suitable for the mechanism and process requirements of microbial fermentation of poultry manure, and can effectively mix the viscous poultry manure with microbial agent and straw powder. It creates a better aerobic environment for material fermentation. Under the condition of loose material, the fermentation temperature can be controlled at 60-70℃ for 3-4 days. The compost after fermentation can be made into slow-release granular fertilizer by rotary drum granulator.

3. The turner machine designed by Tianci Fertilizer Equipment Factory has a balanced power, low energy consumption and large output, which reduces the production cost of bio-organic fertilizer. According to the technical parameters of the machine, the small machine can mix 400-500 cubic meters of fresh cow dung per hour (The equivalent of 100 people working tirelessly at the same time). There are a maximum of 4 or 5 personnel in the whole plant. The turning machine makes the finished fertilizer have obvious price advantage.

4. The overall structure of the tipping machine is reasonable, the whole machine has good rigidity, balanced force, safe and reliable performance, easy to control, strong applicability to the site. Except for the rough and robust frame, all parts are standard parts, which is convenient for operation and maintenance.

Fermented compost can also be used as the raw material of compound fertilizer production line. According to the fertilizer ratio, organic compound fertilizer particles are made, which greatly improves the product quality.