Many people are probably familiar with rapeseed cake. In fact, about 60% of the residue after rapeseed cake oil is pressed remains. Due to the large amount of protein in rapeseed cake, it can become one of the raw materials for organic fertilizer fermentation.

The rapeseed cake fertilizer production line uses decomposed rapeseed cake, soybean residue, and other organic fertilizers to not only fertilize the soil, enhance soil permeability, alleviate soil compaction, prevent root burning, but also inhibit pathogenic bacteria in the soil. Reduce the occurrence of soil borne diseases, but if rapeseed cakes, bean dregs, and other materials do not mature, they not only cannot fully exert their effects, but also are not conducive to the growth of vegetables, flowers, and fruits.

The production process of organic fertilizer production equipment mainly involves mixing organic solid waste with a moisture content of less than 60%, such as chicken manure, pig manure, cow manure, duck manure, household waste, sugar residue, distiller’s grains, sludge, drug residue, sugar residue, mushroom waste, rice husk, weeds, straw, monosodium glutamate plant waste, etc., as the main raw materials. Microbial fermentation agents are added to mix well, and aerobic continuous fermentation is carried out to fully decompose, sterilize, deodorize, and remove water, After fermentation, decomposition, drying, and crushing of organic waste with a moisture content of 30-35%, magnetic separation and screening are carried out. Then, the raw materials with binders and other components that need to be compatible are measured, batched, and mixed (or further dried to produce powdered organic fertilizer) in an automated batching and mixing system according to the ratio requirements. The fully mixed materials are uniformly and continuously fed into a granulator by a belt conveyor for granulation, Then, it is dried by a dryer with low temperature and high air volume (≤ 65 ℃) before cooling and screening. The finished particles are coated by a coating machine (with brightener and anti caking agent added), transported by a belt conveyor to the finished product silo, and measured by a computer automatic quantitative packaging system. The finished products packaged in 40-50kg/bag are then stacked and stored.

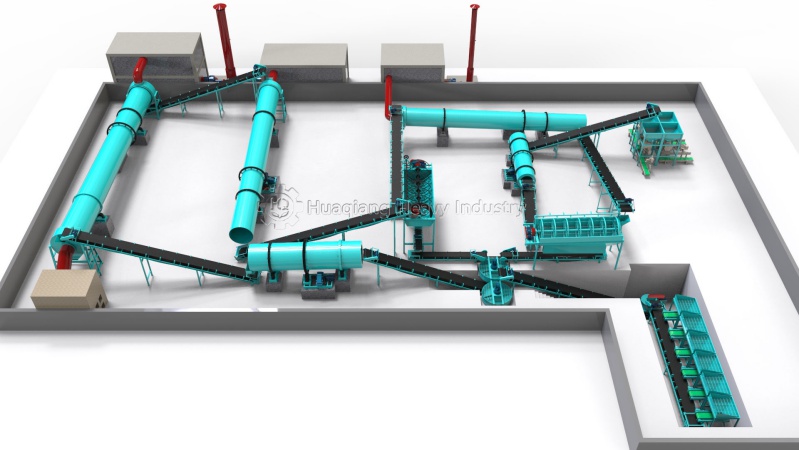

The rapeseed cake fertilizer processing production line includes fermentation equipment, granulation equipment, crushing equipment, mixing equipment, screening equipment, cooling equipment, drying equipment, coating equipment, automatic packaging equipment, and other technological processes.