How to use chicken manure organic fertilizer equipment to process fertilizer?

1. The dehydrator dries fresh chicken manure

Fresh chicken manure has high moisture content, so it is necessary to separate the liquid and solid in the chicken manure through a solid-liquid separator.

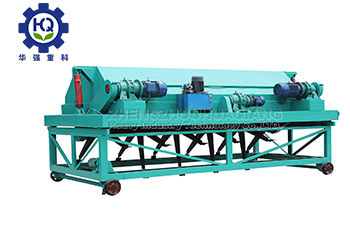

2. Use a chicken manure turner for composting

Composted chicken manure is better for fertilizer and healthier. At the same time, you can also use fermented chicken manure to sell directly.

3. Broken fermented organic chicken manure

This process is the key to the granulation of chicken manure. Using a semi-wet pulverizer, it can be conveniently agglomerated into powder.

4. Mix the crushed chicken manure powder evenly

In order to get evenly distributed chicken manure, an organic fertilizer mixer is essential in the process of making chicken manure. We can provide you with a pan mixer for your use. High mixing efficiency and small footprint.

5. Chicken manure granulation equipment granulated chicken manure for sale

Making chicken manure pellet machine plays an important role in the process of making chicken manure. Without a machine, pellets cannot be made. Common organic fertilizer granulators include: npk fertilizer granulator, rotary drum granulator, disc granulator machine, new organic fertilizer granulator, new two-in-one organic fertilizer granulator, flat die granulator machine, ring die granulator, each granulator has its own production characteristics, and the fertilizer granulator machine price varies. There are three types of new organic fertilizer granulation, rotary drum granulator and disc granulator machine for your choice. Each one can meet your requirements.

6. Drum dryer drum cooler drying and cooling granular chicken manure fertilizer

The finished chicken manure pellets are in a state of high temperature. In order for the pellets to be in good condition, the temperature must be lowered. It makes chicken manure treatment equipment fast.

7. Screening and packaging

.jpg)

.jpg)