The raw materials for producing organic fertilizers are quite extensive, with common ones being poultry manure such as chicken manure, pig manure, cow manure, and sheep manure. Such raw materials need to undergo biological fermentation and then meet the standards of harmless treatment, in order to further produce commercial organic fertilizers. In general, the moisture content of raw materials is high, and a certain proportion of dry materials need to be added for moisture adjustment, such as straw powder, mushroom residue, etc.

Taking sheep manure as an example, pile it up on the site, sprinkle a special fermentation agent for sheep manure composting on the surface of the raw materials, and add an appropriate amount of dry/auxiliary materials according to the moisture content. The general ratio of raw materials and auxiliary materials is 3:1, and the width and height of the pile are determined based on the respective composting machine model.

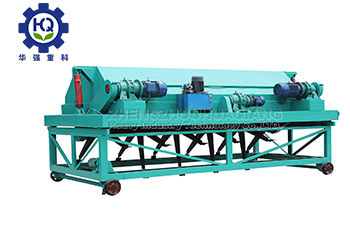

Then, the organic fertilizer composting machine walks on top of the material pile, evenly flipping, stirring, and crushing the raw materials, so that the sheep manure and dry material auxiliary materials and bacterial strains are fully stirred and evenly mixed. The composting machine also has a crushing function, even if there are large pieces of sheep manure or dry material auxiliary materials, under the action of the composting machine, the large pieces of materials can be crushed and decomposed to facilitate full fermentation.

After the organic fertilizer composting machine flips over, a new flat material pile is formed, and the new pile is in a fluffy and loose state, creating a favorable aerobic state for material fermentation, which is very conducive to the production and fermentation of organic fertilizers. In this state, the flipped pile can be raised to a high fermentation temperature within 24 hours, allowing the pile to maintain high temperature for 2-3 days, and then flipped again. In this state, it has basically become fat in 7 days.

In high temperatures, bacteria, grass seeds, and insect eggs in sheep manure are killed, and large molecular proteins are decomposed into small molecular proteins that are beneficial for crop absorption. During the biological fermentation process, it can effectively prevent the generation of harmful and odorous gases such as hydrogen sulfide, amine gas, and indole in feces, and completely eliminate the odor in feces.

With high temperature and flipping, the moisture in the raw materials will gradually decrease. The general fermentation cycle is 12-15 days, and the fastest fermentation can be completed in 7 days, and the pile can be collected. The moisture content will also decrease to about 30%. We can continue with the next step of deep processing, such as screening, crushing, and granulation.

As long as the early fermentation work is done well, the quality of organic fertilizers will be better, and the later deep processing process will be easier to carry out, such as granulation, without problems such as difficulty in pelletizing.

In summary, it can be seen that the organic fertilizer composting machine plays a crucial role in the production and application of organic fertilizers, and it is crucial to choose a suitable high-quality and cost-effective organic fertilizer composting machine.