The rationality of the process, equipment, and construction layout of the organic fertilizer production line directly affects the infrastructure area and investment amount. The basic principles of factory layout design are based on saving, reducing investment, effectively and fully utilizing existing space, effectively utilizing planned investment, and fully meeting production objectives. The reasonable layout of the process equipment factory should start from its processes and principles.

.jpg)

In order to achieve a reasonable layout of the process equipment workshop and factory design, judgments should be made from three aspects: raw materials, processing technology, and deep processing requirements.

1. The impact of raw materials on the process equipment and factory design of organic fertilizer production lines. Due to differences in raw materials, the production process is affected, and most organic fertilizer raw materials are affected by pollution.

One scenario is that during the raw material pretreatment process, the manufacturer can directly preprocess the raw materials on the farm or farmers, then close and transport them to the manufacturer;

Another scenario is to collect untreated waste directly from farmers and farms, and preprocess it in factories. These two methods directly affect the construction of the processing area.

2. Factors affecting the fermentation process. The fermentation process should be carried out based on the quantity of materials.

The current fermentation process that meets national production standards is aerobic fermentation, and the fermentation cycle consists of two parts: fermentation, maturation, and secondary aging. In order to meet the standards, it is advisable to choose tank fermentation or stack fermentation as much as possible. Compared to the two, with the same production capacity requirements, stack fermentation occupies a larger factory area.

Another factor that affects the fermentation process is the fermentation equipment used. Tank fermentation often uses a mobile car with multiple tanks for fermentation, and the flipping process directly realizes the movement of materials towards the discharge port. The fermentation tank can be transferred during the secondary aging stage to achieve continuous fermentation;

However, the use of walking composting machines or flipping machines in stackers results in inherent inconvenience in material transfer. The secondary aging process often involves in-situ aging, which affects the fermentation cycle.

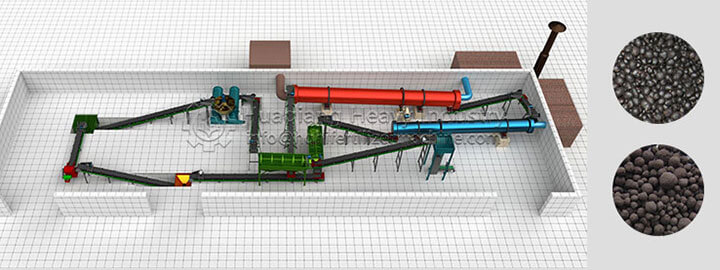

3. The process impact during the later stage of deep processing. The post processing technology of organic fertilizer production line equipment can be divided into powder organic fertilizer production line technology and granular organic fertilizer production line technology, with significant differences in occupied area and equipment infrastructure investment.

Starting from the production line technology of powdered organic fertilizer, the processing technology of powdered organic fertilizer is that after the raw materials are fermented and matured, the main equipment only needs processes such as crushing, stirring, and packaging to be sold. Simply put, the production line process of powdered organic fertilizer is part of the particle processing technology.

In terms of the production process of granular organic fertilizer, in addition to processes such as crushing, stirring, and packaging, drying, granulation, particle grading, and particle packaging are also required. Therefore, particle processing technology often chooses processing production lines with an annual output of over 10000 tons, while small capacity enterprises often choose powder fertilizer processing technology.

.jpg)

.jpg)

.jpg)

.jpg)