The specific fermentation process of organic fertilizer turning machine for processing fertilizers

The workflow of an organic fertilizer turning machine usually follows the following steps:

Raw material deployment:

Evenly lay the prepared organic materials, such as livestock manure, crop straw, etc., in the fermentation bed or composting field.

The laying thickness of raw materials is usually determined based on the type of material and fermentation requirements.

Start the stacker:

According to the needs of the fermentation process, set the working parameters of the organic fertilizer turning machine, such as turning frequency, turning depth, etc.

Start the flipping machine to begin flipping the pile.

Pile flipping homework:

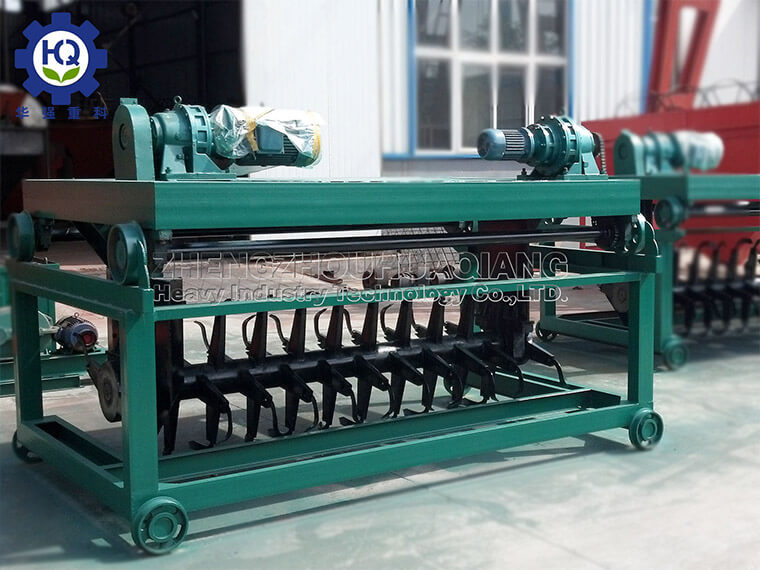

The organic fertilizer turning machine uses its rotating turning shovel or rake teeth to turn the materials in the pile up and down, achieving material mixing and ventilation.

This process helps to increase the oxygen concentration inside the reactor, promoting the growth and metabolic activity of microorganisms.

Adjust temperature and humidity:

During the flipping process, the temperature and humidity of the pile can be adjusted by controlling the flipping frequency and depth to maintain optimal fermentation conditions.

For certain specific fermentation processes, such as aerobic fermentation or anaerobic fermentation, special temperature or humidity control measures may be required.

Fermentation process:

After a period of flipping, organic materials undergo biodegradation reactions, generating heat and promoting microbial activity.

As fermentation progresses, the temperature of the heap will rise and gradually decrease after reaching a certain peak, which is a sign of vigorous microbial activity.

Mature stage:

When the temperature of the heap begins to steadily decrease and reaches a lower level, it indicates that the fermentation process is nearing completion and the organic materials have entered the mature stage.

At this stage, microbial activity slows down, organic matter further decomposes, and stable organic fertilizers are formed.

Subsequent processing:

Mature organic fertilizers can undergo subsequent treatments such as screening, crushing, and drying to meet different usage requirements.

The processed organic fertilizer can be used for fertilizing farmland, improving soil structure, and providing the nutrients needed by plants.

Equipment maintenance:

After each flipping operation, clean and maintain the organic fertilizer flipping machine to ensure its normal operation and extend its service life.

Through the above workflow, the organic fertilizer turning machine can efficiently process organic materials, produce high-quality organic fertilizers, reduce environmental pollution, and promote sustainable agricultural development.

.jpg)

.jpg)