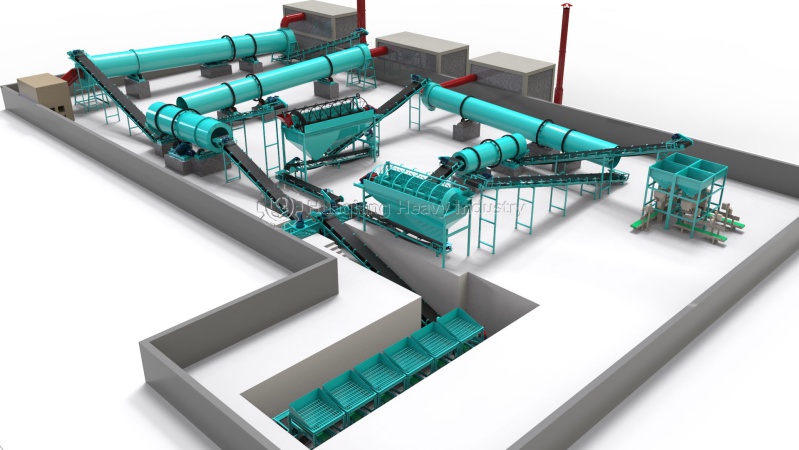

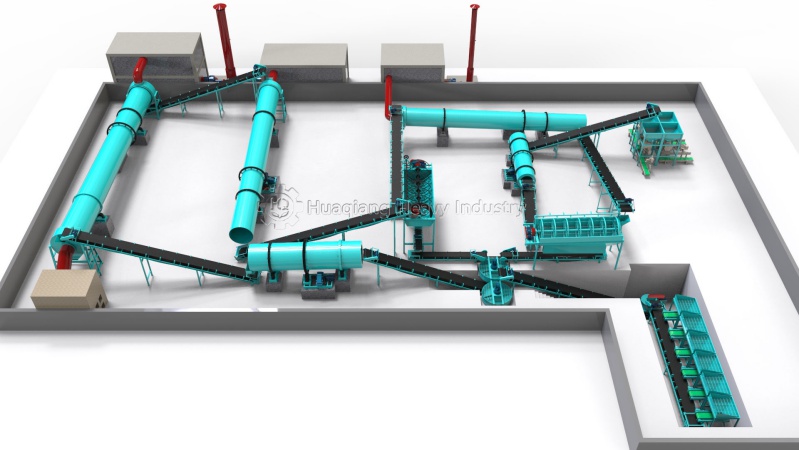

The organic fertilizer production line converts organic raw materials into efficient agricultural fertilizers

Organic fertilizer production line is an industrial equipment specifically used for producing organic fertilizers, which converts organic raw materials into efficient agricultural fertilizers through a series of fine process flows. Organic fertilizers are increasingly favored by farmers for their benefits to soil and crop health, therefore, organic fertilizer production lines play an increasingly important role in modern agricultural production.

The organic fertilizer production line usually includes the following key links:

Raw material pretreatment: including screening, crushing, and mixing of organic raw materials to ensure the quality and consistency of the raw materials. The raw materials can be animal manure, crop residues, urban organic waste, etc.

Composting: By using a composting turner, the raw materials are flipped, ventilated, and fermented to accelerate the decomposition and maturation of organic matter, while achieving the effects of deodorization and sterilization.

Dehydration: Use a dehydrator to remove excess water from the compost for subsequent granulation and packaging.

Granulation: By using a granulator to compress dehydrated organic matter into granules, the stability and usability of fertilizers are improved.

Drying and cooling: The dryer is used to reduce the moisture content of the fertilizer, while the cooler is used to lower the temperature of the fertilizer to a suitable range for packaging and storage.

Screening and packaging: The screening machine is used to separate particles that do not meet the standards, while the packaging machine is responsible for quantitatively packaging qualified fertilizers.

Characteristics of organic fertilizer production lines

Environmentally friendly and efficient: Organic fertilizer production lines can effectively convert organic waste into fertilizers, reduce environmental pollution, and improve resource recycling efficiency.

High degree of automation: Modern organic fertilizer production lines usually have the characteristics of high automation, which can reduce manual operations, improve production efficiency and safety.

Good flexibility: The production line can adjust process parameters and equipment configuration according to different raw materials and market demands, producing different types and specifications of organic fertilizers.

Stable product quality: Through precise control and standardized production processes, the organic fertilizer production line can ensure the stability and reliability of product quality.

Organic fertilizer production lines are widely used in various agricultural production fields, including planting, animal husbandry, horticulture, etc. It can be used to produce various organic fertilizers, such as bio organic fertilizers, compound organic fertilizers, microbial organic fertilizers, etc., to meet the needs of different crops and soils.

With the increasing emphasis on environmental protection and sustainable development, the application prospects of organic fertilizer production lines will become increasingly broad. By using organic fertilizer production lines, not only can agricultural production efficiency be improved, but also resource recycling can be promoted, agricultural ecological environment can be protected, and important contributions can be made to achieving green agriculture and sustainable development.

.jpg)

.jpg)