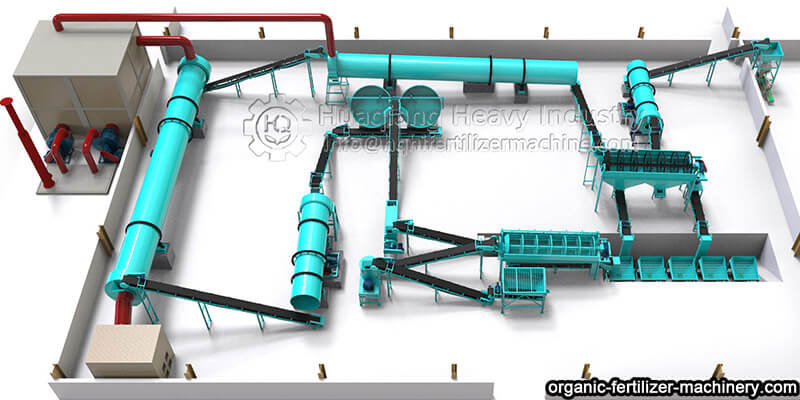

The complete set of automated organic fertilizer production line includes: manure dewatering machine, fermentation tipping machine, organic fertilizer crusher, organic fertilizer mixer, organic fertilizer granulator, rotary dryer, cooling machine, drum screening machine, automatic packaging machine, belt conveyor, coating machine, etc.

1. Organic fertilizer tipping machine: Its function is to mix animal manure with crushed crop straw, undergo high-temperature fermentation and decomposition, deodorize and sterilize, completely eliminate harmful bacteria in the material, and prepare for the next process;

2. Organic fertilizer crusher: Crush fermented materials, the finer they are, the more rounded the particles produced, and the better their appearance;

3. Forklift feeding silo: plays a role in uniform feeding and does not cause material to accumulate at the feeding port;

4. Horizontal mixer: adding elements such as nitrogen, phosphorus, and potassium, bidirectional spiral stirring is more uniform, suitable for mixing various materials;

5. Organic fertilizer granulation machines: Organic fertilizer granulation machines are divided into three types of conventional granulation equipment: disc granulation machines, toothed granulation machines, and three-in-one composite granulation machines. The prices of the three types of granulation equipment are completely different, and customers need to customize them according to their own needs;

6. Organic fertilizer dryer and cooler: The hot air is introduced into the dryer through an induced draft fan to dry the raw materials. The moisture content of the dried raw materials does not exceed 30%. Due to the high temperature of the dried particles, a cooling machine is needed to cool them down;

7. Drum screening machine: The function of this equipment is to screen out particles that do not meet the standard size, and transport them to the crushing process through a belt conveyor for new crushing and granulation. The qualified particles will be transported to the encapsulation process through screening;

8. Organic fertilizer coating machine: Add a layer of coating agent outside the particles to make the appearance of the particles more round and beautiful, sell well, and facilitate long-term storage of materials;

9. Fully automatic quantitative packaging scale: This equipment is the last process in the organic fertilizer production line, and its function is to automatically package particles, with the advantages of saving labor and more accurate packaging.

The organic fertilizer production line can effectively solve the environmental pollution caused by organic waste in animal husbandry, reduce surface water eutrophication caused by pollution, and improve the safety and quality of agricultural products. Fully consuming human green and organic food has laid a good foundation, and the ecological and environmental benefits are extremely significant.