Granular potassium fertilizer: A comprehensive guide to benefits, production, and application

Granular potassium fertilizer is a commonly used, high-quality form of potassium fertilizer in agricultural production. It offers the advantages of convenient storage and transportation, and stable fertilizer efficiency. Its production relies on specialized equipment, and its application requires careful consideration of crop needs, balancing increased efficiency with soil health.

The core benefits focus on practical application and effectiveness. Compared to powdered potassium fertilizer, granular potassium fertilizer is less prone to caking and dust, making storage and handling more convenient and reducing nutrient waste; its uniform particle size is suitable for mechanized application, ensuring even distribution and preventing seedling burn, saving labor and increasing efficiency; and its slow-release properties provide a sustained supply of potassium, improving absorption and utilization.

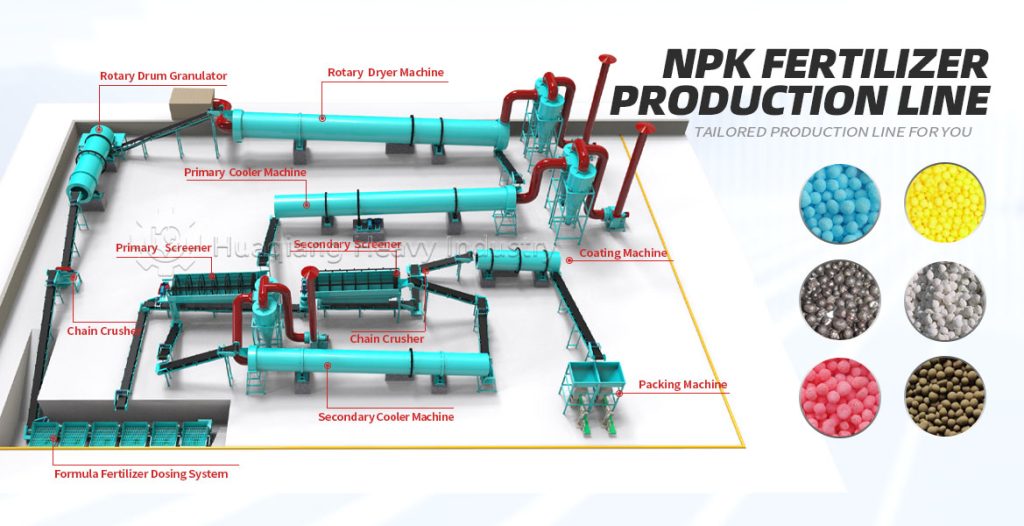

The production process emphasizes standardization and adaptability. Granular potassium fertilizer is often produced using NPK fertilizer production lines, employing granulation machines such as double roller press granulators and rotary drum granulators. This process requires minimal binders and high-temperature drying, and is compatible with raw materials such as potassium chloride and potassium sulfate, allowing for precise control of particle strength and size.

Application must follow scientific principles. It is suitable for field crops such as corn and rice, as well as economic crops such as tomatoes and fruit trees, with a focus on application during critical potassium-demanding stages such as stem elongation and fruit development; it can be applied through furrow application or broadcasting, and combined with organic fertilizers to enhance effectiveness; and the application rate should be controlled based on soil fertility to avoid excessive application and nutrient antagonism.

In summary, the value of granular potassium fertilizer lies in its standardized production and scientific application. It leverages its physical form to improve practicality and contributes to efficient and sustainable agricultural production through precise nutrient supply.