NPK fertilizer production: How are tiny pellets changing modern agriculture?

In modern agricultural production, the NPK fertilizer production line plays a vital role in ensuring global food security through its precise design and efficient operation. This complete NPK manufacturing process transforms raw materials into nutritionally balanced fertilizer pellets, with each step showcasing the brilliance of modern engineering.

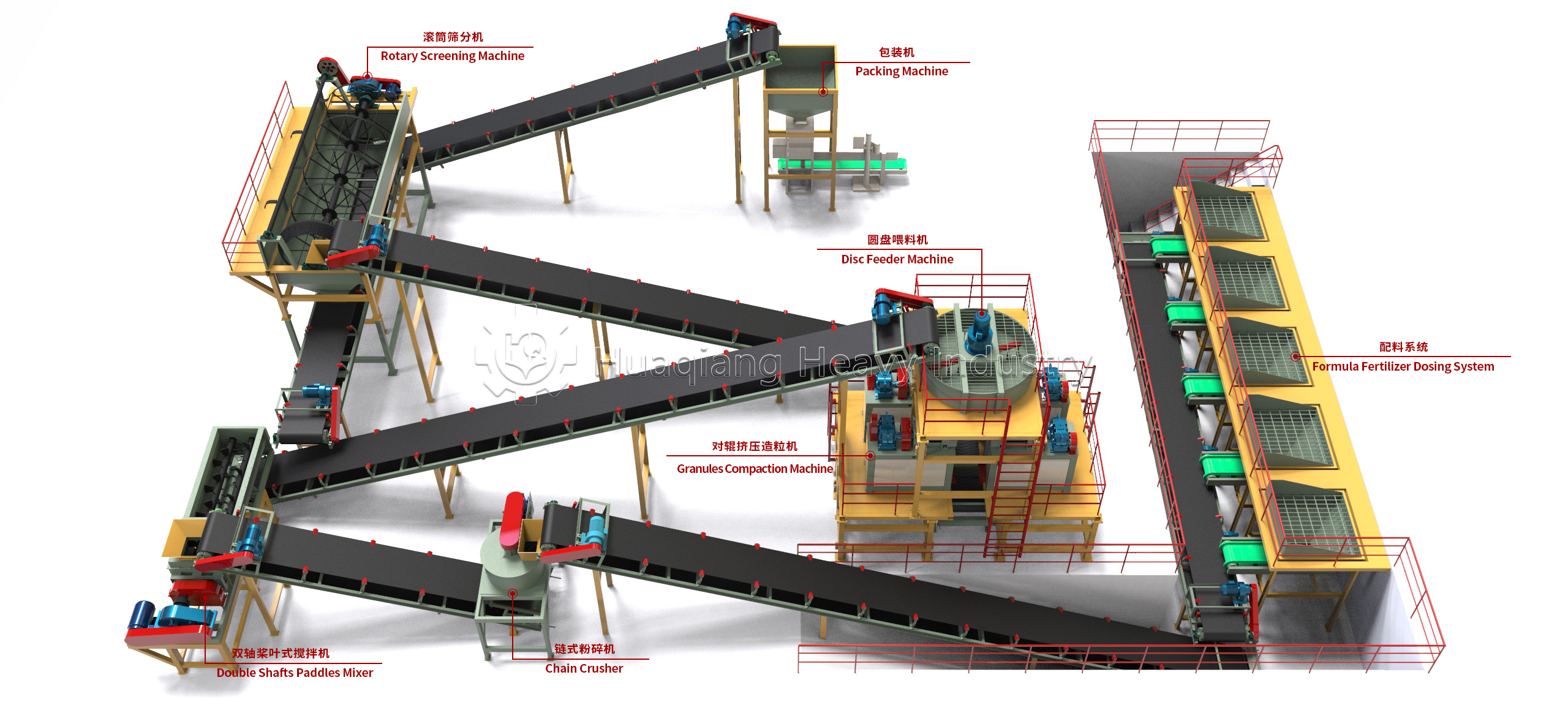

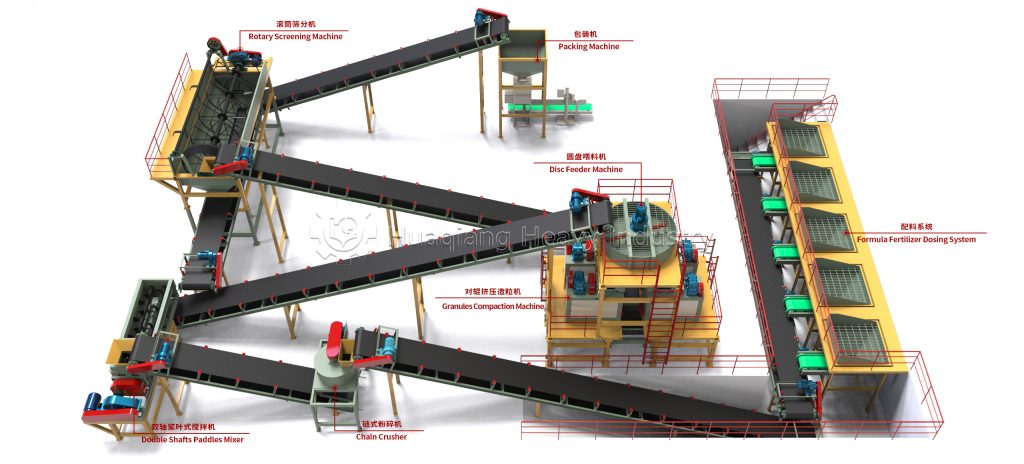

The entire NPK production process begins with precise ingredient proportioning. Raw materials such as urea, phosphate, and potash are accurately measured before being fed into crushers to achieve the ideal particle size for mixing. Subsequently, double-shaft paddle mixers or V-type mixers thoroughly blend these materials, laying a solid foundation for the subsequent granulation process.

Granulation represents the core of the NPK fertilizer manufacturing process. After adding appropriate moisture to achieve optimal humidity, disc granulators, drum granulators, or extrusion granulators transform the mixed materials into uniform pellets. These machines utilize rotational or pressure forces to create consistently sized, high-quality particles.

In the complete npk production line, the subsequent drying and cooling stages are equally crucial to the npk fertilizer production process. Fluidized bed dryers or rotary drum dryers effectively remove moisture from the pellets, while cooling drums reduce the temperature to suitable levels, ensuring product stability. Screening equipment further refines the selection of qualified particles, guaranteeing consistent product size and completing the transformation into high-quality NPK fertilizer.

To enhance fertilizer performance, some production lines additionally employ coating processes that create a protective film on the pellet surface, improving moisture resistance and controlling nutrient release rates. Finally, automatic packaging machines complete precise weighing and packaging, while advanced PLC control systems monitor the entire process to ensure every step is executed flawlessly.

This intelligent production line not only improves fertilizer quality but also promotes sustainable agricultural development, providing solid support for global food security.