Unlocking the key to high-efficiency operation of organic fertilizer production lines

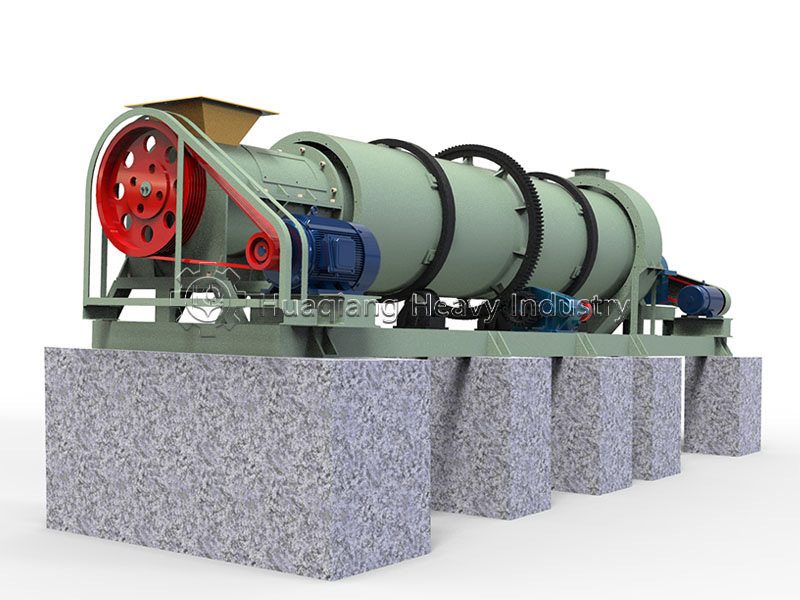

The continuous efficiency and product qualification rate of organic fertilizer production lines depend critically on the suitability of the core organic fertilizer production equipment. The drum fertilizer dryer, as the “efficiency hub” of post-processing, not only undertakes the core task of material dehydration but also connects the preceding and succeeding processes, solving bottlenecks and providing crucial support for large-scale production.

Its core value lies in “efficient dehydration + process integration.” After granulation, the moisture content of organic fertilizer granules reaches 20%-30%. If drying is not timely, clumping and mildew can occur, disrupting the process. The drum fertilizer dryer, through the rotation of the inclined drum and the turning action of internal baffles, ensures sufficient contact between the material and hot air for uniform dehydration, precisely controlling moisture content to a safe range of 12%-14%. With a processing capacity of several tons to tens of tons per hour, it is perfectly suited for continuous operation of the production line.

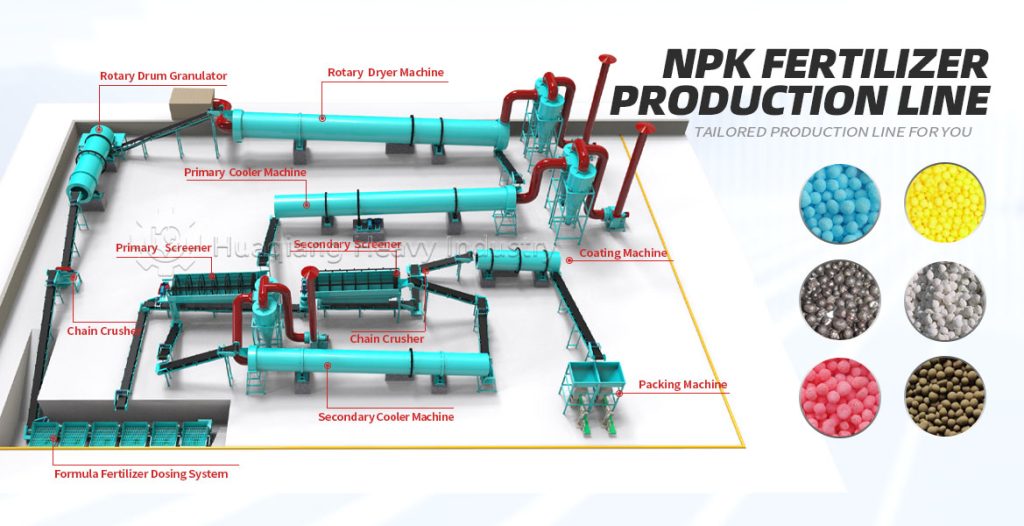

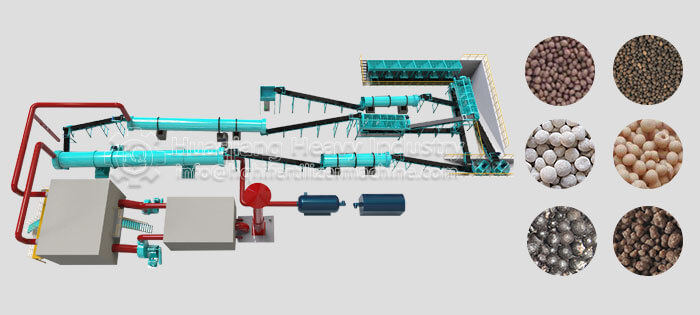

As a key piece of organic fertilizer production equipment, its adaptability is extremely strong. Whether it’s livestock and poultry manure, straw-based organic granules, or organic-inorganic compound granules, it can be adapted by adjusting the hot air temperature and drum rotation speed, preventing high temperatures from damaging nutrients while ensuring effective drying. At the same time, it seamlessly connects with organic fertilizer granulators, coolers, and screening machines, forming a closed-loop process, reducing transportation losses and improving the overall efficiency of the production line.

For large-scale, standardized organic fertilizer projects, the drum fertilizer dryer is a core component for improving overall efficiency. Its stable operation can significantly reduce the rate of product re-moisturization, improve the qualification rate, shorten the production cycle, and contribute to the efficient and low-cost operation of the organic fertilizer production line.