How much profit is there from the production and processing of straw organic fertilizer?

Advantages of organic fertilizer manufacturing process in processing straw waste

1.Harmless treatment of agricultural waste and scientific and reasonable production. It can solve the problem of processing organic matter such as kitchen waste, weeds, straws, etc., realize the regeneration and utilization of waste organic resources, and realize waste reduction and resource treatment.

2. Organic fertilizer processing plant changed traditional compost into biological compost. At present, the treatment of livestock and poultry manure is relatively simple. Exposure to the sun or septic tank has strong odor, which is easy to attract flies and mosquitoes, and affect the environment and the physical and mental health of the masses. The project uses animal manure and straw to produce organic fertilizer, which can effectively solve the problems of soil, water and air pollution, and improve the living environment.

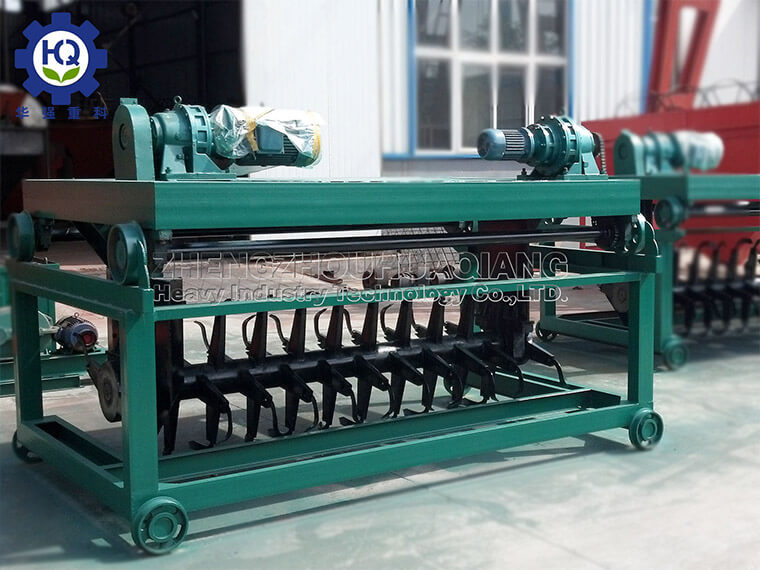

3. Convert straw waste into ecological organic fertilizer through biological fermentation technology. At present, agricultural straw returning to the field will cause air pollution during the combustion process. In this project, agricultural wastes such as straws can be made into organic fertilizer, and the compost turning machine can process the compost to achieve high-efficiency and high-quality fermentation. The decomposed organic fertilizer can be directly applied and is easily absorbed by crops. There is no discharge of waste water, odor and waste residue during the production process. At the same time, the project will play a very active role in avoiding stacks of firewood, reducing environmental pollution, and promoting the prohibition of straw burning, and can achieve good economic, ecological and social benefits..jpg)

Organic fertilizer processing plants have good benefits

We provide NPK fertilizer manufacturing process and organic fertilizer production equipment to meet the needs of fertilizer plants. Since the investment and construction of a factory that purchased our organic fertilizer equipment, the production of commercial organic fertilizer has been in short supply, and it has been favored by surrounding farmers. The nearby vegetable greenhouses, fruit tree tea gardens and other large planting bases have come here and signed many sales contracts.

Moreover, the organic fertilizer plant for a large number of surrounding customers to give preferential prices for sales, the implementation of a small profit and high sales business model, not only improve environmental pollution, provide convenient services for surrounding farmers, but also create great economic benefits for itself.

.jpg)

.jpg)