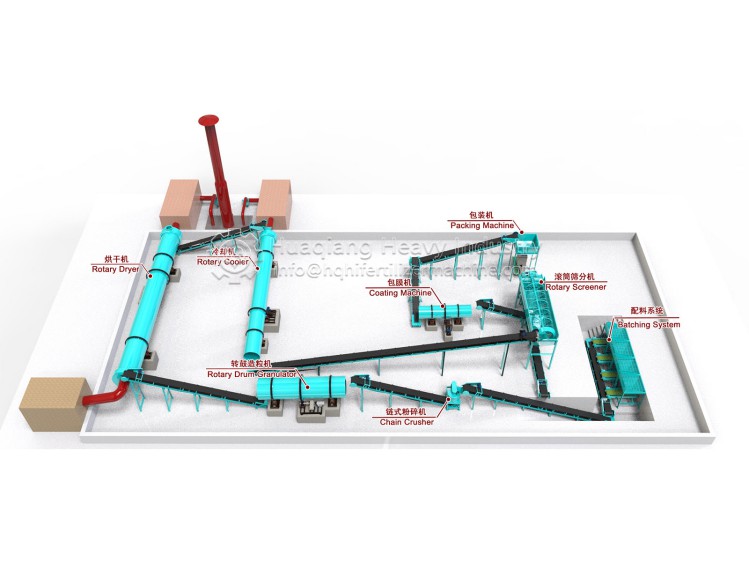

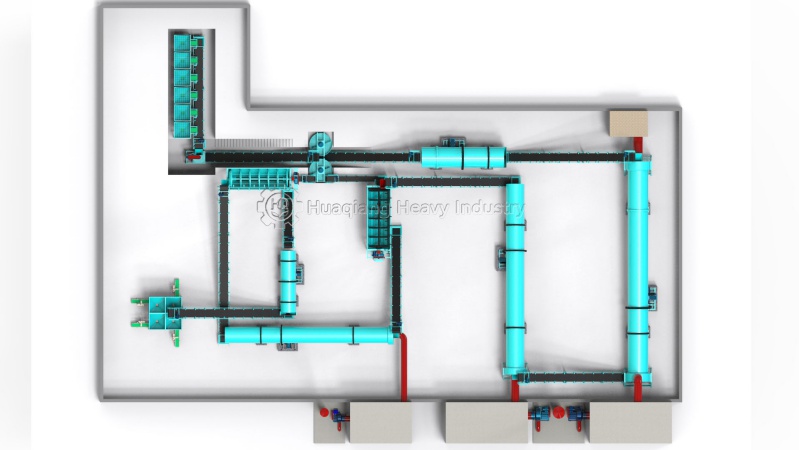

The process flow of small and medium-sized cow manure organic fertilizer production line

Cow manure is a popular raw material for organic fertilizers, and the manufacturing equipment and process have been gradually improved and matured. In addition, some policies and subsidies from organic fertilizer factories currently make organic fertilizer production practitioners quite popular. The commonly used organic fertilizer production equipment on the market currently includes a complete process from organic fertilizer fermentation to granular packaging. Overall, making organic fertilizer is still very convenient..jpg)

The process flow of small and medium-sized cow manure organic fertilizer production line:

Place fresh cow manure with a moisture content of 65% -85% and an appropriate amount of auxiliary materials (dry straw, crushed grass, dry cow manure, etc.) in a fermentation tank for fermentation, while thoroughly stirring with a fermentation equipment (organic fertilizer mixer);

The organic fertilizer flipper continuously flips to adjust water content and carbon to nitrogen ratio (C/N); The mixed fresh cow manure is fermented for 7 days under suitable temperature and oxygen conditions; Then it is sent into the dryer, where the cow manure blocks come into full contact with hot air and quickly lose surface moisture; Due to the high-speed rotating crushing equipment inside the dryer, the cow manure blocks are constantly crushed and dehydrated, completing the drying process; Measurement, bagging, packaging, and human storage.

When producing balanced composite organic fertilizers, the N content of dried cow manure is measured during the intermediate stage of drying cow manure P. The content of K element, and then based on various crops, flowers, grasslands, fruits, and vegetables, balance the compound organic fertilizer N P. The requirement for K element is to add it quantitatively to the drying cow manure, stir thoroughly with a mixer, measure, bag, package, and store in person.

.jpg)

.jpg)

.jpg)

.jpg)