Raw Material Characteristics and Advantages

Oil Palm Empty Fruit Bunch (OPEFB) is the main by-product generated during palm oil processing, with approximately 1.1-1.3 tons of empty fruit bunches produced for every ton of palm oil. This agricultural waste possesses unique physical and chemical characteristics that make it an excellent raw material for organic fertilizer. OPEFB is rich in cellulose (approximately 45%), hemicellulose (about 25%), and lignin (around 20%), while also containing abundant mineral elements such as potassium (K), calcium (Ca), magnesium (Mg), as well as essential plant nutrients like nitrogen (N) and phosphorus (P).

Nutritional analysis shows that fresh empty fruit bunches typically contain about 60-65% moisture, with dry matter containing approximately 0.5-0.8% nitrogen, 0.1-0.2% phosphorus, 2.0-3.5% potassium, and rich organic matter content (about 85-90%). These characteristics make it an ideal base material for organic fertilizer production.

Processing Technology

Transforming empty fruit bunches into high-quality organic fertilizer requires systematic processing. First, pretreatment involves shredding using specialized crushers to reduce the material to 2-5 cm particles, increasing surface area to facilitate subsequent fermentation. This is followed by the composting fermentation stage, using windrow or trough fermentation systems, with carbon to nitrogen ratio controlled at the optimal range of 25-30:1, typically requiring the addition of nitrogen sources such as chicken manure or chemical nitrogen fertilizers for adjustment.

Temperature control is crucial during the fermentation process. The high-temperature phase (55-65°C) needs to be maintained for 10-15 days to eliminate pathogens and weed seeds, followed by the medium-temperature phase (45-55°C) for further maturation. The entire fermentation cycle typically requires 45-60 days, with regular turning necessary to ensure proper aeration and oxygen supply. Modern processing plants often employ microbial inoculation technology, adding specific decomposing agents to accelerate lignocellulose degradation, reducing the fermentation period to 30-40 days.

Product Characteristics and Application Effects

Fully matured OPEFB organic fertilizer appears dark brown with the characteristic odor of fertile soil, with stable pH values between 6.5-7.5. Its organic matter content can reach 40-50%, total nutrient content (N+P₂O₅+K₂O) is approximately 3-5%, while also containing abundant trace elements and beneficial microorganisms. This organic fertilizer demonstrates significant effects in improving soil physical structure, enhancing soil porosity, increasing water and nutrient retention capacity, and promoting the formation of soil aggregates.

Field experiments show that applying OPEFB organic fertilizer in oil palm plantations can increase fresh fruit bunch yield by 15-25%, while significantly improving soil fertility indicators. After application, soil organic matter content can increase by 0.5-1.0 percentage points, soil microbial population increases by 2-3 times, effectively alleviating soil acidification and compaction problems caused by long-term exclusive use of chemical fertilizers.

Environmental Benefits and Economic Value

The development and utilization of OPEFB organic fertilizer offers significant environmental benefits. For every ton of empty fruit bunches used to produce organic fertilizer, approximately 0.8 tons of CO₂ equivalent greenhouse gas emissions can be reduced, avoiding air pollution caused by open burning, while also reducing chemical fertilizer usage by 20-30%. From an economic perspective, the investment payback period for establishing an OPEFB organic fertilizer processing plant is typically 3-5 years, demonstrating good economic returns.

Furthermore, OPEFB organic fertilizer production creates new employment opportunities locally, forming a complete industrial chain from raw material collection, processing, to product sales and application. This recycling model aligns with sustainable development principles, transforming the oil palm industry from a linear “resource-product-waste” model to a circular “resource-product-renewable resource” model.

Application Prospects and Development Directions

With the growing global demand for sustainable agriculture and organic food, the market prospects for OPEFB organic fertilizer are promising. Future development directions include developing specialized compound organic fertilizer formulations optimized for different crop nutritional requirements; researching rapid fermentation technologies to further shorten production cycles; and exploring co-fermentation with other agricultural wastes to improve resource utilization efficiency.

Simultaneously, it is necessary to establish complete quality standard systems and market promotion mechanisms to ensure stable product quality and improve farmers’ awareness and acceptance of OPEFB organic fertilizer. Through technological innovation and policy support, OPEFB organic fertilizer is expected to become an important organic fertilizer source in tropical regions, making significant contributions to sustainable agricultural development.

Sustainable Innovation: The Future of OPEFB Fertilizer Production

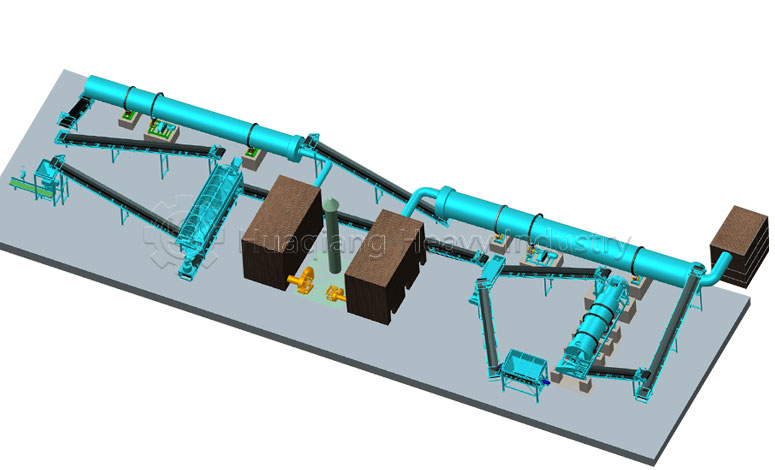

The transformation of Oil Palm Empty Fruit Bunches into high-quality organic fertilizer represents a perfect synergy between waste management and sustainable agriculture. Modern organic fertilizer production line systems leverage advanced equipment like the large wheel compost turner and chain compost turner to optimize the organic fertilizer fermentation process, ensuring efficient decomposition of lignocellulosic materials. Following fermentation, specialized granulation equipment such as the double roller press granulator or rotary drum granulator transforms the composted material into uniform, easy-to-handle fertilizer granules through precise drum granulation processes.

For facilities seeking product diversification, the same infrastructure can support both traditional organic fertilizer and bio organic fertilizer production line operations, while separate npk fertilizer production line systems can be integrated for comprehensive product offerings. The npk fertilizer manufacturing process typically employs different fertilizer granulator technologies, but shares the same commitment to quality and efficiency. As the wheel compost turner and other turning machines continue to evolve, they enable larger-scale, more cost-effective processing of OPEFB materials. This integrated approach to organic fertilizer production not only addresses waste management challenges in the palm oil industry but also creates valuable soil amendments that support sustainable agricultural practices worldwide, closing the nutrient loop in one of the world’s most important tropical crops.

.jpg)