Major Chemical Fertilizers and Application Guide

In modern agricultural production, chemical fertilizers play an irreplaceable role. Understanding the characteristics and proper usage methods of different fertilizer varieties is crucial for improving crop yield and quality. This article introduces several major chemical fertilizer varieties and their applications.

Ammonium Phosphate Fertilizers

Monoammonium phosphate (MAP) and diammonium phosphate (DAP) are two important phosphorus fertilizer varieties. Monoammonium phosphate contains approximately 11% nitrogen and 52% phosphorus, with good water solubility, making it suitable for use as base fertilizer and top dressing. Diammonium phosphate contains 18% nitrogen and 46% phosphorus, serving as an important raw material in compound fertilizers.

Both fertilizers have good physical properties, making them easy to store and apply. They are particularly suitable for use in phosphorus-deficient soils, effectively promoting crop root development, flowering, and fruiting. Application rates should be determined based on soil test results to avoid resource waste and environmental pollution from excessive use.

NPK Compound Fertilizers

Ammonium sulfate, as an important nitrogen fertilizer, contains approximately 21% nitrogen and 24% sulfur. It not only provides the nitrogen nutrition required by crops but also supplements sulfur, making it particularly suitable for use in sulfur-deficient soils.

NPK fertilizers are compound fertilizers scientifically proportioned according to crop needs and soil conditions. Different NPK ratios can meet the nutritional requirements of crops at different growth stages, achieving precise fertilization and improving fertilizer utilization efficiency.

Phosphorus and Potassium Fertilizer Varieties

Phosphate fertilizers include various types, with superphosphate being one of the most traditional phosphorus fertilizers. It contains 14-20% available phosphorus, along with abundant calcium and sulfur elements. Superphosphate is suitable for most crops and soil types, with particularly significant effects in acidic soils.

Potassium fertilizer is one of the essential nutrient elements for crop growth, playing an important role in improving crop stress resistance and quality. Common potassium fertilizer varieties include potassium chloride and potassium sulfate. Selection should consider the potassium requirements of crops and soil conditions.

Special Role of Sulfur

Sulfur is not only a raw material for sulfuric acid production but also has important uses in agriculture. It can be used as a soil amendment, particularly in alkaline soils, effectively reducing soil pH and improving soil structure. Additionally, sulfur is an important component of certain pesticides and fertilizers.

Rational selection and scientific use of chemical fertilizers are important aspects of achieving sustainable agricultural development. Growers should choose the most suitable fertilizer varieties and application methods based on soil conditions, crop needs, and environmental factors, ensuring high crop yield and quality while protecting the agricultural ecological environment.

Summary and Extension

Modern agriculture relies on precise fertilizer application, with NPK compound fertilizers playing a pivotal role in meeting crop nutritional demands. The NPK fertilizer manufacturing process begins with accurate ingredient proportioning using advanced fertilizer mixer machines and NPK blending machines. These equipment ensure homogeneous mixing of nitrogen, phosphorus, and potassium components according to crop-specific formulations, forming the foundation for quality fertilizer production.

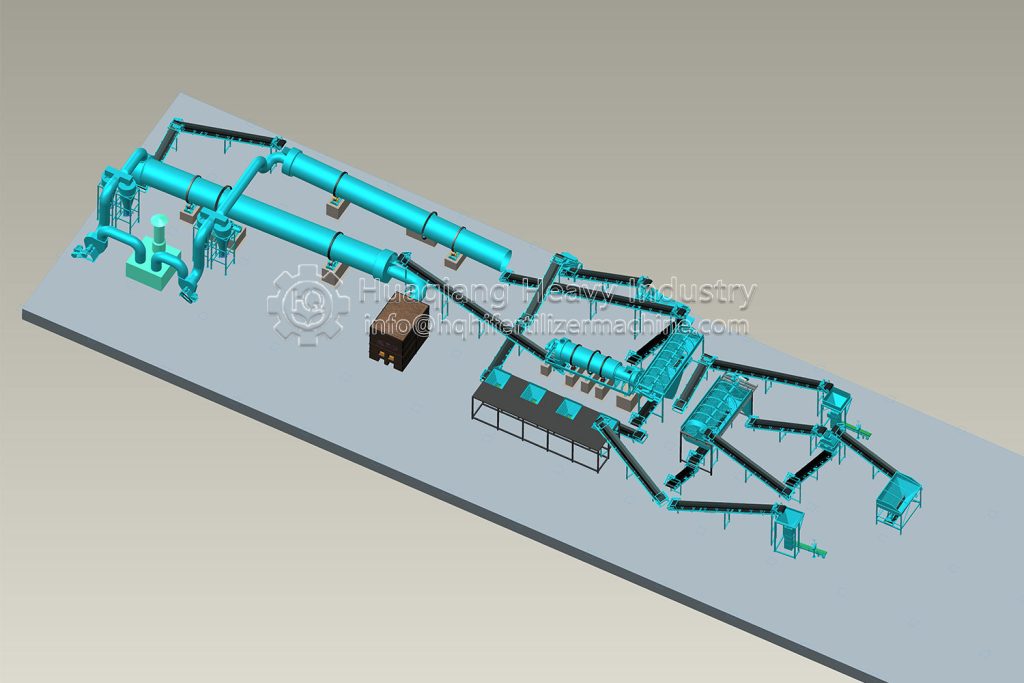

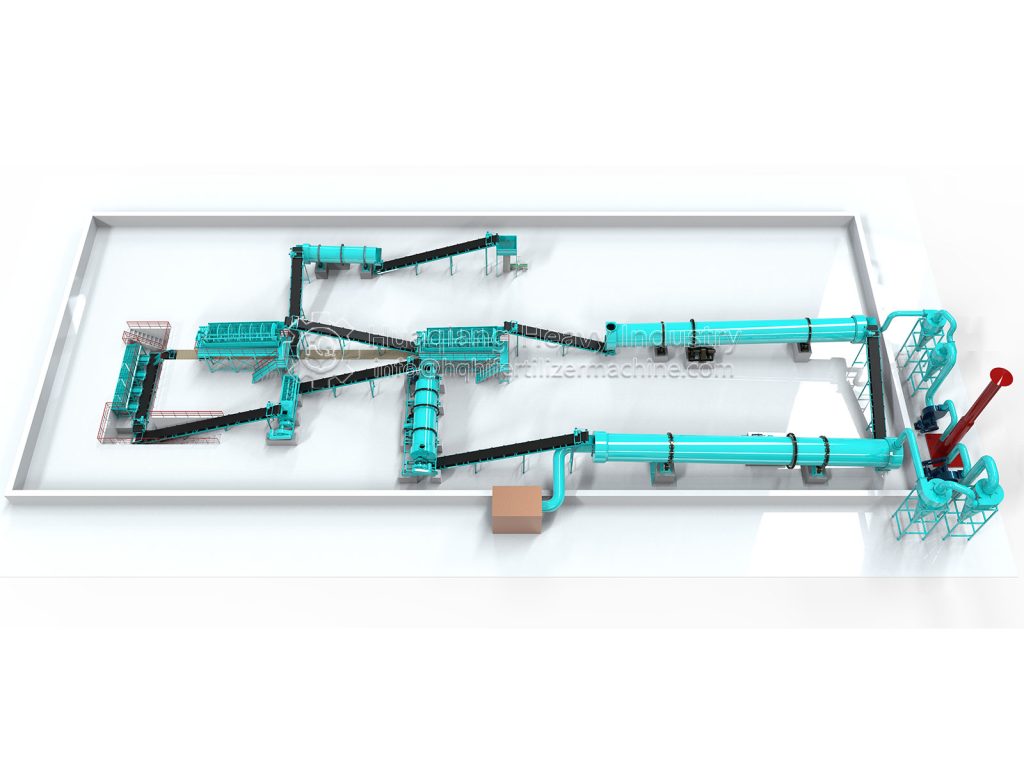

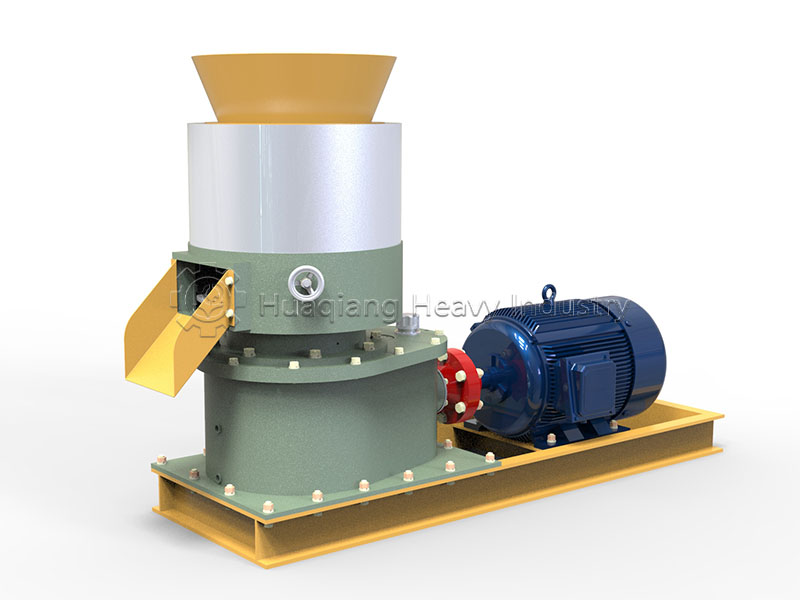

Granulation represents the core stage of NPK production process, where mixed materials are transformed into uniform granules. The disc granulator machine utilizes centrifugal force to create spherical particles, while the NPK fertilizer granulator employs agitation or compaction methods. For bulk blending fertilizer operations, specialized NPK bulk blending machines enable direct mixing of granular raw materials. The complete NPK fertilizer production line integrates crushing, mixing, granulating, drying, and packaging equipment to achieve continuous manufacturing of NPK fertilizer.

The fertilizer granulation process significantly improves product characteristics, reducing dust and enhancing nutrient release control. Modern NPK manufacturing facilities employ automated NPK fertilizer machines that optimize resource utilization while minimizing environmental impact. Through scientific fertilizer granulation technology and proper equipment selection, producers can create tailored fertilizers that address specific soil deficiencies and crop requirements, ultimately supporting sustainable agricultural development.