As global agriculture shifts toward sustainable practices, manure-based fertilizers have emerged as a cornerstone of eco-friendly farming. By converting organic waste into nutrient-rich resources, these fertilizers support soil health while reducing environmental pollution. Based on processing methods, nutrient composition, and functional properties, manure-derived fertilizers can be categorized into four distinct types, each addressing specific agricultural needs—from foundational soil conditioning to high-value functional applications.

1. Ordinary Organic Fertilizer (Basic Type)

This is the most fundamental form of manure-based fertilizer. Through controlled composting, raw manure undergoes decomposition to eliminate pathogens and weed seeds, resulting in a stable product rich in organic matter. It typically contains ≥45% organic matter but has relatively low NPK content (≥5%). Its primary role lies in improving soil structure, enhancing water retention, and increasing microbial activity. Commonly used as a base fertilizer for field crops like wheat and corn, it is also ideal for rehabilitating degraded soils in orchards or vegetable gardens. Over time, it mitigates soil compaction and boosts long-term fertility.

2. Organic-Inorganic Compound Fertilizer (Balanced Type)

To bridge the gap between organic and conventional fertilizers, this type blends composted manure with synthetic nutrients such as urea, monoammonium phosphate, or potassium sulfate. It maintains ≥20% organic matter while offering NPK levels of ≥15%. This combination ensures rapid nutrient availability for crops alongside sustained soil improvement. The granular form facilitates mechanized application and storage. Widely adopted in cash crops like vegetables, fruits, and flowers, it serves as a versatile base or top-dressing fertilizer for scenarios demanding both immediate nutrition and soil preservation.

3. Bio-Organic Fertilizer (Functional Type)

Enriched with beneficial microorganisms like Bacillus subtilis, phosphorus-solubilizing bacteria, or nitrogen-fixing bacteria, bio-organic fertilizers transcend mere nutrient supply. They contain ≥40% organic matter and a critical threshold of effective live bacteria (≥200 million per gram). These microbes suppress soil-borne diseases, unlock immobilized phosphorus and potassium, and stimulate root development. Packaged in sealed bags to preserve microbial viability, they are particularly valuable for addressing continuous cropping obstacles in greenhouse farming or supporting high-value crops like strawberries and blueberries under reduced-chemical regimes.

4. Organic Water-Soluble Fertilizer (Rapid-Action Type)

Through advanced processes like enzymatic hydrolysis or chelation, organic matter in composted manure is broken down into water-soluble molecules such as humic acid or amino acids. This formulation allows for direct application via irrigation systems or foliar spraying, with absorption efficiency exceeding 80%. It provides quick relief for nutrient deficiencies while enhancing the soil microenvironment. Available in liquid or soluble powder forms, it is often supplemented with water-soluble inorganic nutrients. Ideal for critical growth stages (e.g., flowering or fruit expansion) and precision agriculture systems like drip irrigation, it offers a practical solution for fast-paced, resource-efficient farming.

In summary, manure-based fertilizers have evolved from simple soil amendments to sophisticated tools supporting diverse agricultural systems. By selecting the appropriate type—ordinary organic for soil restoration, organic-inorganic for balanced nutrition, bio-organic for microbial benefits, or water-soluble for rapid uptake—farmers worldwide can align productivity with sustainability, turning waste into wealth for future generations.

Summarize

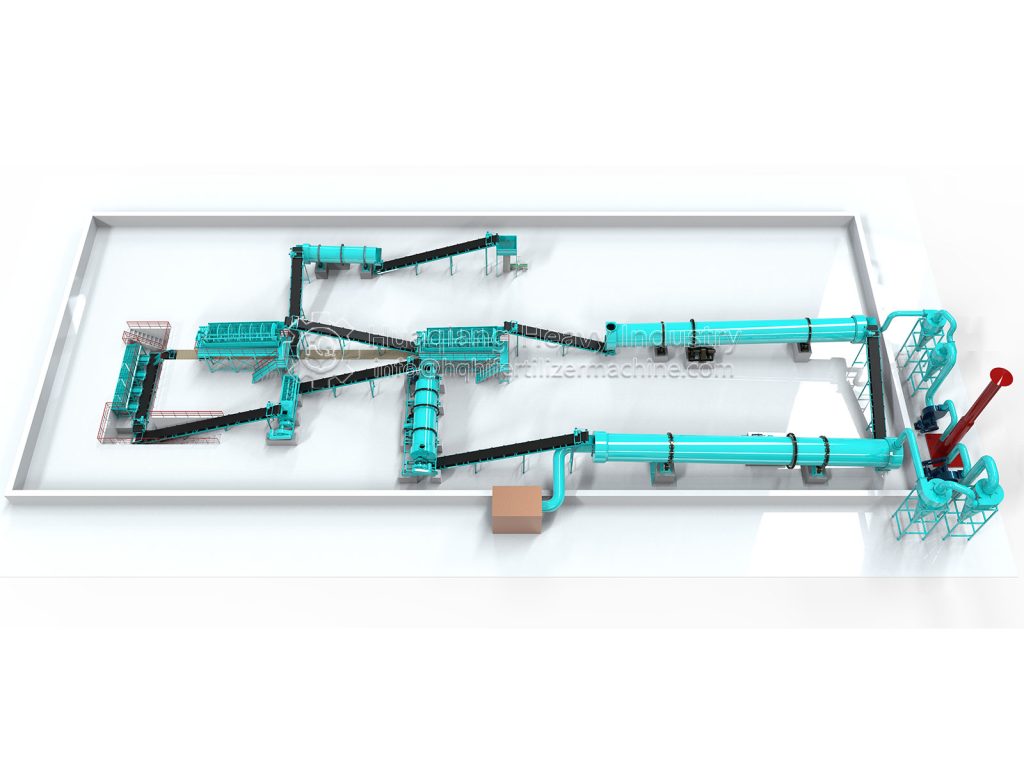

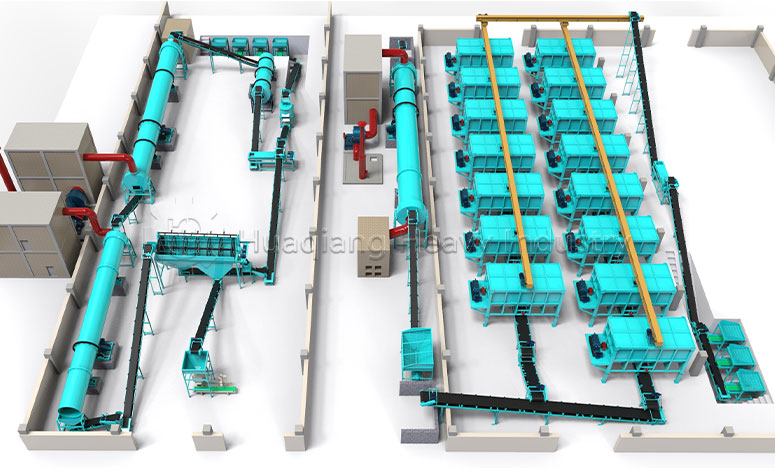

The four categories of manure-based fertilizers represent progressive levels of processing sophistication within an organic fertilizer production line. From basic composting to advanced formulations, each type requires specific fertilizer processing machines to achieve desired characteristics. The ordinary organic fertilizer forms the foundation, while the granular organic-inorganic compounds demand reliable organic fertilizer granulator equipment. For specialized formulations, the choice between different fertilizer granulator types significantly impacts product quality and production efficiency in any organic fertilizer factory.

Granulation technology plays a crucial role in manufacturing these fertilizers, with equipment selection directly affecting the organic fertilizer machinery price. The drum granulator excels in large-scale production of uniform organic-inorganic compounds through its efficient drum granulation process, while the double roller granulator operates on dry compaction principles ideal for heat-sensitive materials. Similarly, in NPK production lines, the NPK fertilizer granulator employs distinct NPK production process methodologies to create balanced nutrient formulations. The fertilizer roller press machine offers another versatile solution for both organic and compound fertilizer production.

Modern organic fertilizer factories must carefully evaluate their equipment portfolio to efficiently produce all four fertilizer categories. The integration of appropriate granulation equipment – whether drum granulator for wet mixing or double roller granulator for dry processing – enables manufacturers to create everything from basic soil conditioners to specialized bio-organic formulations. This equipment versatility allows producers to meet diverse market demands while optimizing their NPK production line capabilities, ultimately determining both production capacity and return on investment through strategic machinery selection and process optimization.