Organic fertilizer production: raw material fermentation → composting and maturation → granulation

In the context of global agricultural sustainability, organic fertilizer production has become a crucial link in resource recycling. The key process of “raw material fermentation → turning and composting → pelletizing” forms a seamless transformation chain from organic waste to commercial fertilizer. This interconnected process, where each step is indispensable, collectively achieves the resource utilization of waste materials.

Composting: The Foundation of Organic Fertilizer Production

The compost turner plays a vital role as a “pre-composting processing equipment” in this process. It converts raw materials such as livestock manure and sludge into composted materials suitable for pelletizing through turning, aeration, and crushing. This process requires precise control of material moisture between 30%-45%, ensuring uniform particle size without large impurities, while maintaining nutrient stability. Inadequate turning that results in incomplete composting will directly affect subsequent pelletizing quality, leading to easily broken granules and potential secondary fermentation causing plant damage during application.

Pelletizing: Adding Value to Commercial Fertilizer

The organic fertilizer granulator serves as the “forming equipment,” responsible for transforming composted materials into valuable granular fertilizer. Using the composted materials processed by the turner as the core raw material, and adding necessary binders and trace elements, it processes loose materials into uniform granules through extrusion and rolling processes. This effectively addresses practical issues such as inconvenient storage, difficult transportation, and uneven application of composted materials, while enhancing the slow-release effect of nutrients. The selection of granulators must match the processing capacity of the turners to ensure continuous and stable operation of the production line.

Synergistic Effects: Producing High-Quality Organic Fertilizer

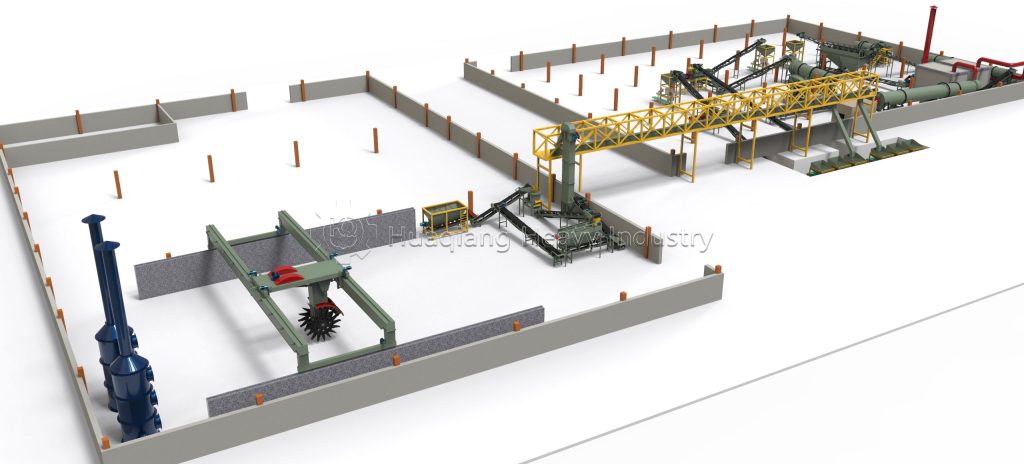

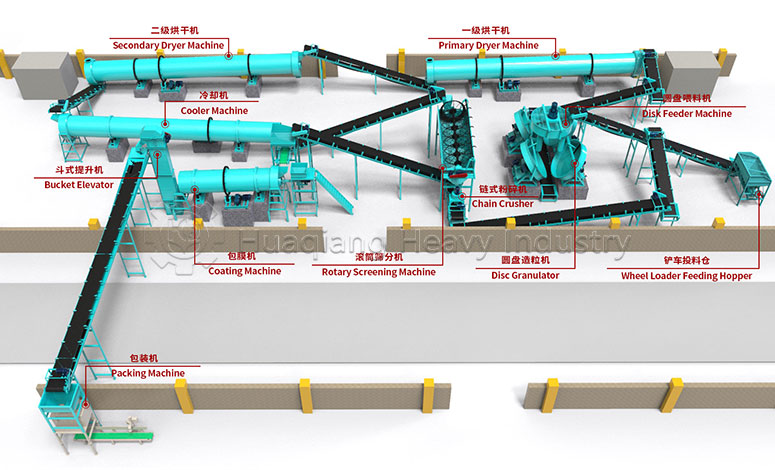

The complete organic fertilizer production process begins with raw material pretreatment, where various organic wastes are mixed and sent to fermentation tanks. Over the next 5-15 days, the turner continuously performs turning operations to complete the aerobic fermentation process. The resulting composted materials undergo screening and drying treatments to adjust moisture to levels suitable for pelletizing. Subsequently, the granulator processes these materials into granules, which are finally cooled and screened to become commercial organic fertilizer ready for market.

In this production chain, the turner determines the composting quality and nutrient activity of the organic fertilizer, while the granulator determines the product’s physical form and performance characteristics. The performance parameters of both must be mutually compatible – the output particle size from the turner directly affects the granulator’s forming rate, while the granulator’s process requirements in turn constrain the turner’s operational standards. This precise coordination ensures that the final product possesses both excellent fertilizer efficiency and superior physical characteristics.

With the growing global demand for sustainable agriculture, modern organic fertilizer production line configurations integrating advanced technologies are making significant contributions to circular economy development. A comprehensive bio organic fertilizer production line typically begins with efficient organic fertilizer fermentation systems, where equipment selection between a versatile chain compost turner and high-capacity large wheel compost turner significantly impacts processing efficiency. The large wheel compost turning machine offers superior aeration for large-scale operations, while the robust wheel compost turner provides reliable performance for medium-scale organic fertilizer factory requirements.

Following the fermentation phase, material moves to granulation where the organic fertilizer granulator selection becomes critical – with the drum granulator standing out for its high-capacity processing of uniform pellets. When evaluating organic fertilizer machinery price, operators must consider the complete system integration rather than individual components. This holistic approach to organic fertilizer production line design not only achieves optimal resource utilization of organic waste materials but also produces high-quality fertilizers that reduce dependence on conventional NPK production line outputs. Through this technological synergy, modern organic fertilizer systems provide substantial economic and environmental returns while promoting green development throughout the agricultural sector.

.jpg)

.jpg)

.jpg)