Organic Fertilizer Applications and Production Equipment

Main Application Areas of Organic Fertilizer

Agricultural Production

Organic fertilizer is widely used in field crops, vegetable cultivation, and fruit tree farming. It improves soil structure, enhances soil water and nutrient retention capacity, provides comprehensive nutrition for crops, and significantly improves agricultural product quality and yield.

Landscaping and Greening

In urban landscaping, golf courses, and sports field maintenance, organic fertilizer promotes healthy plant growth, improves soil ecological environment, and reduces the use of chemical fertilizers.

Ecological Restoration

In projects such as mine reclamation, saline-alkali land improvement, and degraded soil restoration, organic fertilizer effectively improves soil physical and chemical properties and accelerates ecosystem recovery.

Key Organic Fertilizer Production Equipment

Main Production Equipment Systems:

- Crushing Equipment:Half-wet material crushers, chain crushers for raw material pretreatment

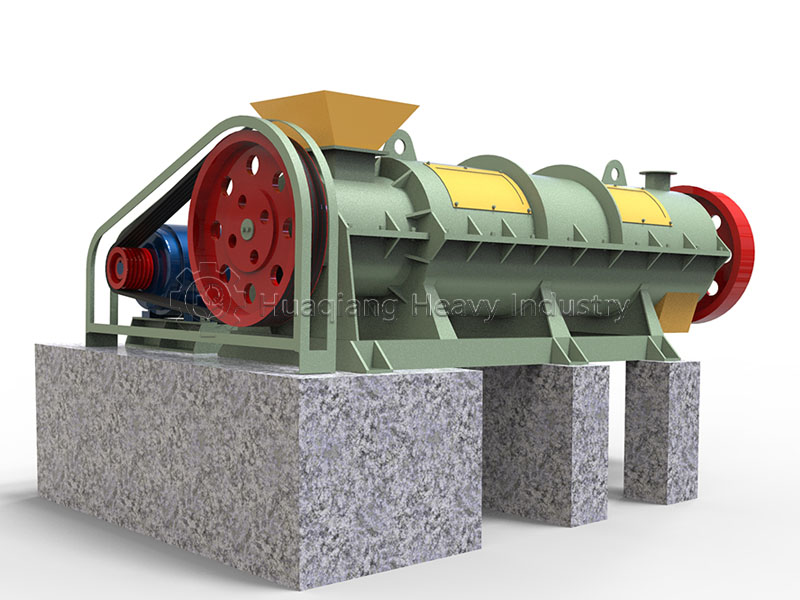

- Mixing Equipment:Dual-shaft mixers, disc mixers to ensure uniform material mixing

- Fermentation Equipment:Trough turners, crawler compost turners to promote organic matter decomposition

- Granulation Equipment:Rotary drum granulators, disc granulators to form uniform particles

- Drying and Cooling Equipment:Rotary dryers, coolers to adjust product moisture and temperature

- Screening and Packaging Equipment:Rotary screening machines, automatic packaging machines for final processing

Environmental Benefits and Sustainable Development

The use of organic fertilizer not only improves agricultural production efficiency but more importantly achieves the resource utilization of agricultural waste. By converting livestock manure, crop straw, and other materials into valuable organic fertilizers, it both solves environmental pollution problems and promotes the development of circular agriculture economy. This “turning waste into treasure” production model provides an effective pathway for achieving sustainable agricultural development.

Comprehensive Production Solutions for Modern Agriculture

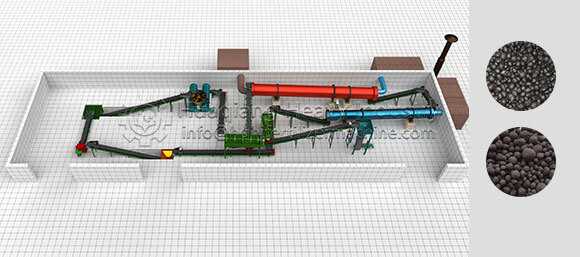

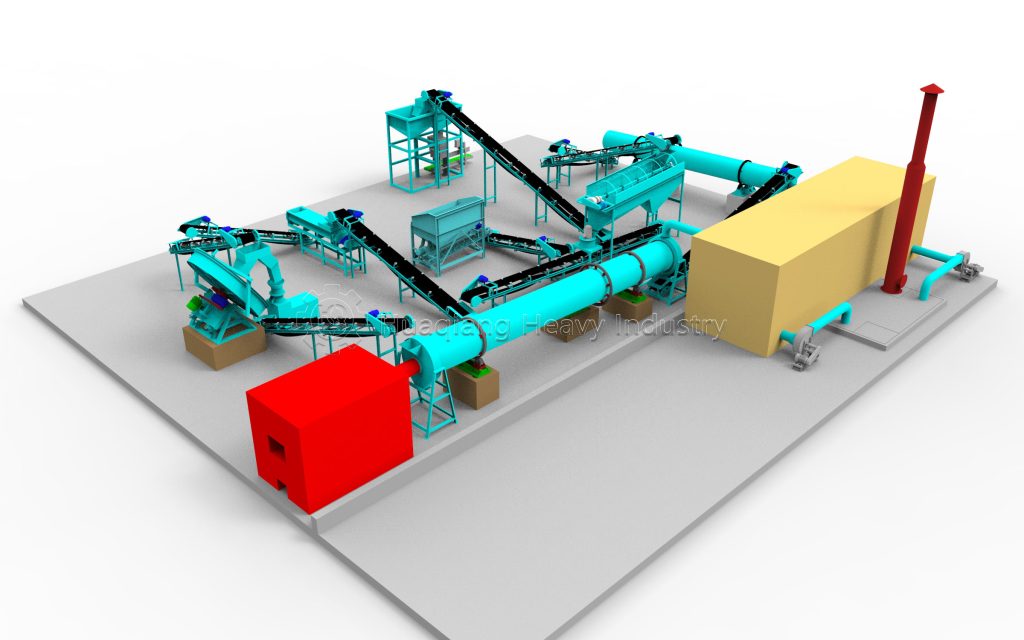

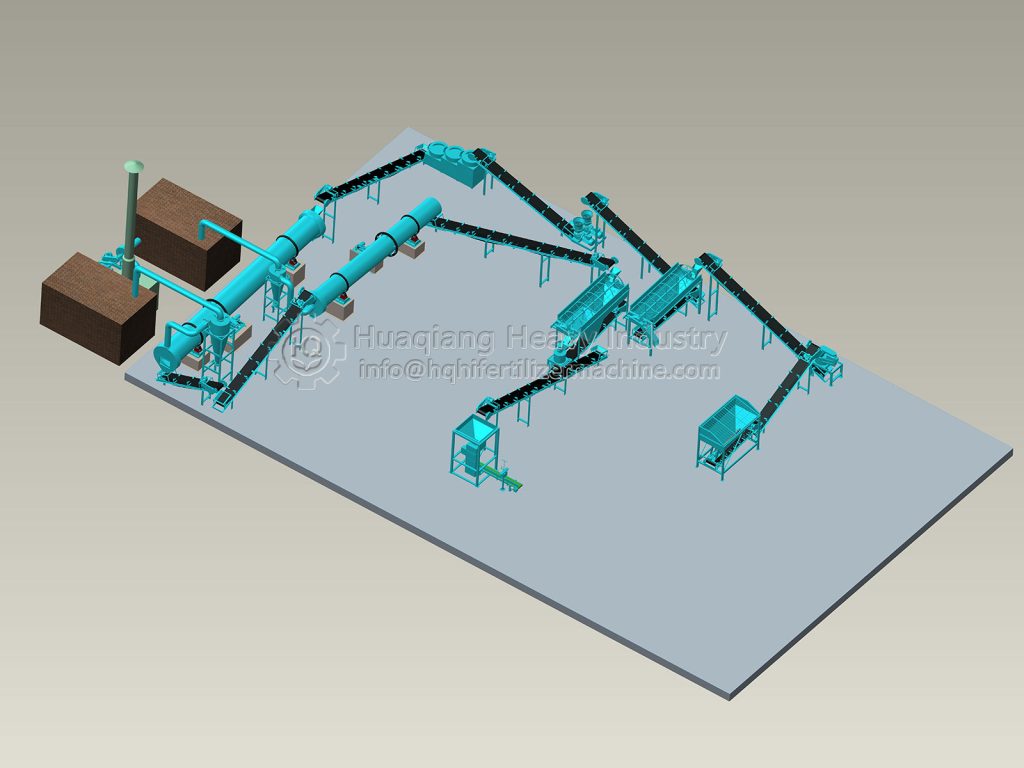

The complete organic fertilizer production line represents an integrated system that transforms organic waste into valuable agricultural resources through sophisticated processing stages. Central to this process is the fermentation phase, where equipment like the chain compost turner and large wheel compost turning machine efficiently manage the organic fertilizer fermentation process, ensuring optimal decomposition and pathogen elimination.

Granulation technology forms the core of fertilizer production, with multiple equipment options available based on specific requirements. The rotary drum granulator (also known as drum granulator) excels in high-capacity drum granulation, while the double roller press granulator (or fertilizer roller press machine) provides alternative compaction granulation. For specialized nutrient formulations, the NPK fertilizer production line implements a precise NPK production process using specialized NPK fertilizer granulator equipment to create balanced nutrient products.

Modern production facilities can choose between various configurations, from the standard organic fertilizer production line to specialized bio organic fertilizer production line systems. The complete NPK fertilizer manufacturing process integrates multiple fertilizer granulator technologies to meet diverse agricultural needs. Whether using a wheel compost turner for fermentation or advanced granulation equipment, these integrated systems support sustainable agriculture by converting organic materials into high-quality fertilizers for various application areas.