A comprehensive analysis of common compound fertilizer production processes

Compound fertilizer production processes are diverse, with core differences focusing on raw material processing, granulation methods, and energy consumption control. Different processes are suited to different fertilizer types and production capacity requirements. The following outlines the core characteristics and application scenarios of four major processes, providing a reference for production selection.

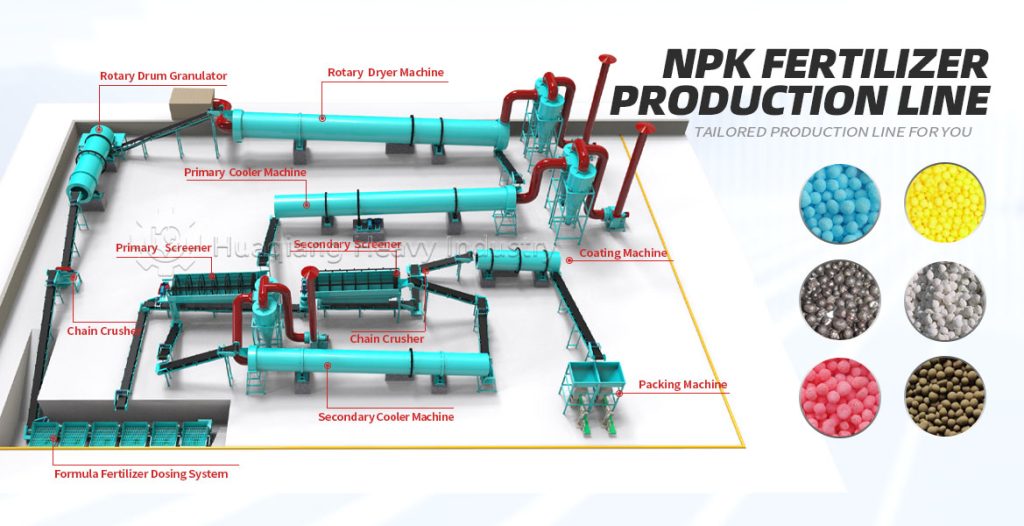

Rotary drum granulation is a traditional mainstream wet process. Raw materials are sprayed, mixed, and granulated in a rotary drum, followed by drying, cooling, and screening to complete production. Its advantages include high production capacity and uniform granules, making it suitable for general-purpose NPK compound fertilizers; its disadvantages include high energy consumption and strict control over raw material moisture content.

Spray granulation emphasizes high efficiency and integration. The raw material slurry is directly sprayed into a granulation tower, where it is rapidly dried and formed by hot air, without the need for additional mixing. It offers uniform nutrient distribution and high efficiency, making it suitable for large-scale production of high-concentration compound fertilizers, but it requires high equipment investment and has stringent requirements for slurry viscosity.

Dry extrusion granulation is an environmentally friendly and energy-saving process. Dry raw materials are directly pressed into shape using a double roller press granulator, eliminating the need for water addition and drying. Energy consumption is more than 30% lower than wet processes, and there is no wastewater or exhaust gas. It is suitable for various raw materials and small-to-medium-scale environmentally friendly production, although the granule strength is slightly lower.

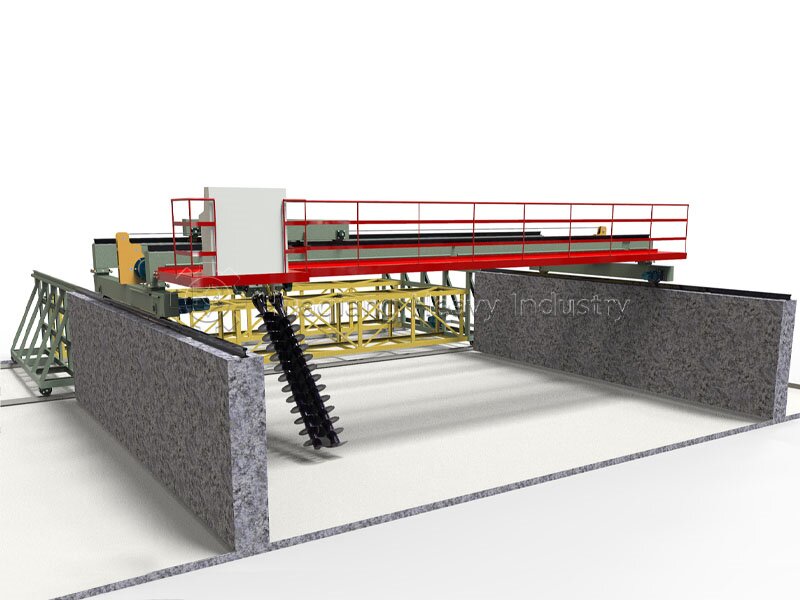

Blending granulation focuses on flexibility. Single fertilizers are mixed according to the formula using a double axis paddle mixer, and then granulated or made into BB fertilizer as needed. It offers flexible formulations and convenient product changes, making it suitable for customized production, but it requires high consistency in raw material particle size.