What are the precautions for using and operating an organic fertilizer granulator

The price of organic fertilizer granulator equipment is closely related to the type and model, and the choice of model also depends on the production demand. Therefore, the key factor in selecting fertilizer granulator equipment. Of course, with different selection options, the corresponding supporting equipment configurations and prices also vary.

What are the precautions for using and operating an organic fertilizer granulator?

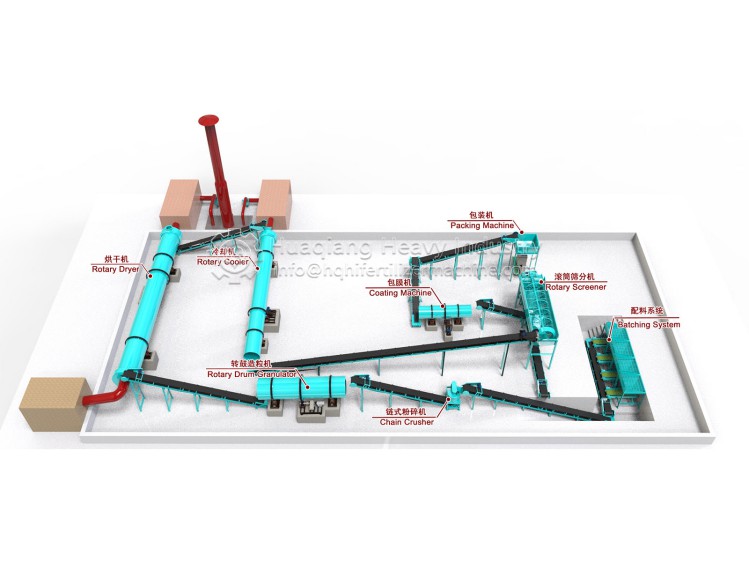

At least two warehouses should be equipped for granulation and powder blending, so that the granulator does not need to be stopped when changing formulas.

Efficient iron removal devices must be installed before 2 materials enter the granulator to protect the granulator.

It is best to place the organic fertilizer granulator directly on the cooling machine and the crusher under the cooling machine.

To prevent particles from falling into the bottom of the warehouse and damaging the vertical spiral chute inside the warehouse.

5. Finished product packaging should be placed behind the finished product warehouse.

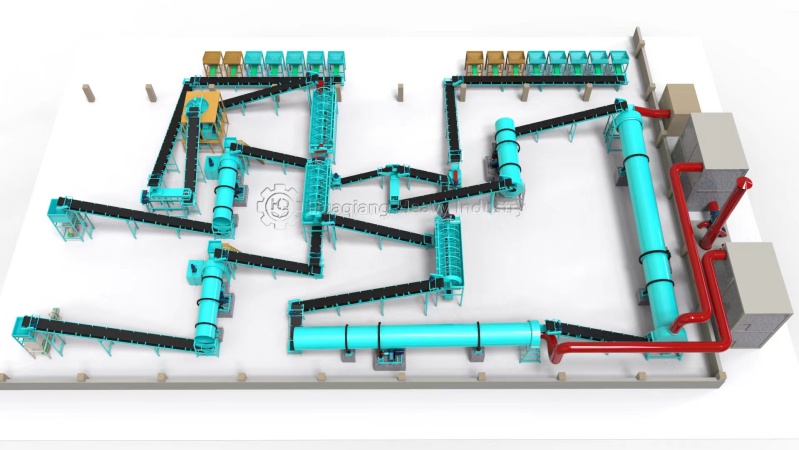

1. Raw material receiving process: Different raw material receiving processes are adopted based on the type, packaging form, and transportation method of the received raw materials. Regardless of the receiving process, raw materials need to undergo quality and weight inspections.

2. The raw materials received by bulk trucks and tank trucks are automatically unloaded into the receiving pit after being weighed by a ground scale. After the raw materials are unloaded into the material receiving pit, they are sent to the vertical silo for storage or directly into the crushing or batching silo through a horizontal conveyor, bucket elevator, initial cleaning magnetic separator, and automatic scale.

.jpg)

.jpg)