The organic fertilizer granulator is one of the most core equipment in organic fertilizer equipment, which has a direct impact on the quality of organic fertilizer particles (roundness, uniformity, fertilizer moisture retention performance, etc.).

So, what are the differences in the several processes of organic fertilizer granulation? What are the impacts on product quality? Different granulation processes for organic fertilizers require different types of granulators, which directly affect the yield, quality, appearance, price, and other aspects of the product.

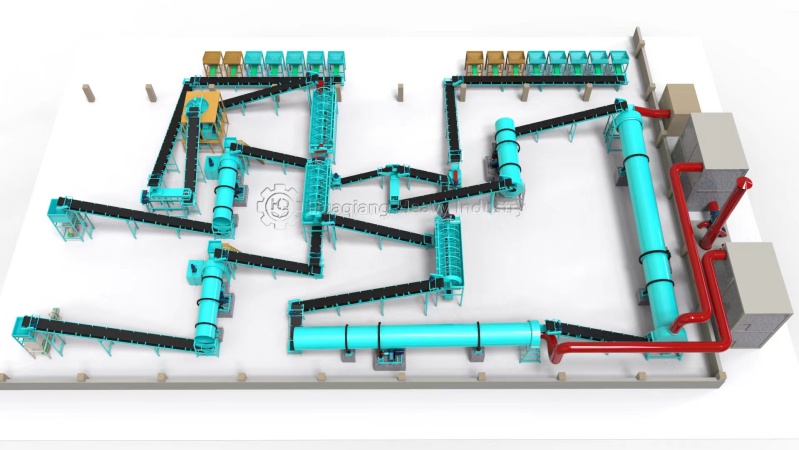

It can be said that the organic fertilizer granulator is the core of the entire production line. The raw materials for making organic fertilizers come from a wide range of sources, including plant residues, peat soil, humic acid, cow manure, chicken manure, sheep manure, duck manure, free manure, sludge, filter sludge from sugar factories, distillery lees, and so on.

For different raw materials and requirements for improving product quality and output, various organic fertilizer equipment manufacturers have developed various granulators, such as roller extrusion granulators, strand rotation granulators, disc granulators, new organic fertilizer granulators, new compound fertilizer granulators, flat mold granulators, ring mold granulators, etc.

If your investment funds are limited or the sales market has not yet opened up, I suggest that you start with a set of powder organic fertilizer production lines. The low price and good quality of powder organic fertilizer equipment will help you open up sales channels. After the sales market opens up, we can increase production and purchase equipment, and it is not too late to start the particle production line.