Plants need to be fertilized because most soils do not provide the essential nutrients needed for optimal growth. Even if you’re lucky enough to start with good soil, as plants grow, they absorb nutrients and make the soil less fertile. By fertilizing, you can replace lost nutrients and ensure that this year’s plants have the food they need to grow.

The main nutrients required by plants include carbon, hydrogen, oxygen, nitrogen, phosphorus, potassium and so on. Carbon from CO2 in the air, hydrogen from water, oxygen from water, and nitrogen from air help plants make the proteins they need to make new tissues. Phosphorus stimulates root growth, helps plants germinate and flower, improves vitality and increases seed size. Potassium enhances the overall vitality of the plant. It helps plants make carbohydrates and provides disease resistance.

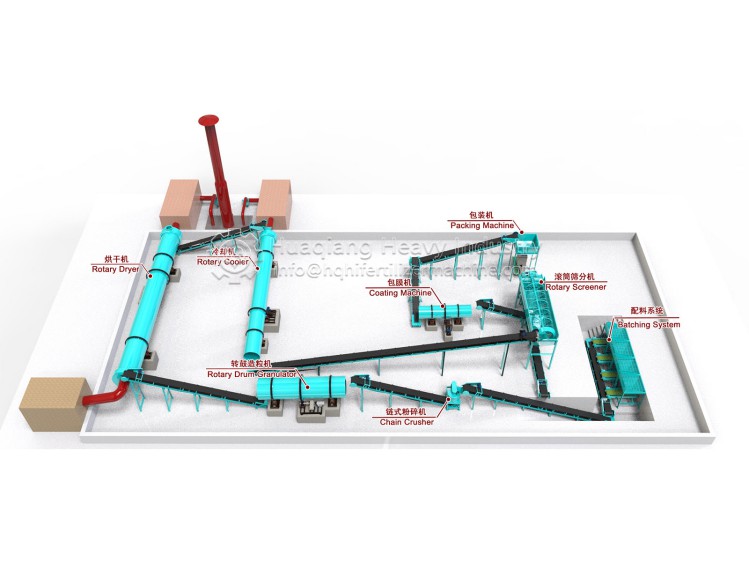

NPK fertilizer production line is composed of the crusher, fertilizer mixing machine, granulator, screening machine, fertilizer coating machine, fertilizer automatic packaging machine. Compared to NPK fertilizer granulation line, NPK fertilizer

The mixing line is fairly simple. Generally speaking, nitrogen, phosphorus and potassium fertilizer mixing production line includes automatic batching machine, BB fertilizer mixer, storage hopper and fertilizer packaging machine. Our company provides npk fertilizer production line and various equipment, which can quickly improve efficiency, increase the output of npk fertilizer, and save labor cost.

Nitrogen, phosphorus and potassium fertilizers produced using npk production lines can rapidly promote plant growth, and they can also leach into streams and ponds due to the high water solubility of synthetic fertilizers. Synthetic fertilizers have an advantage in early spring. Because they are water-soluble, plants can use them even when the soil is still cold and soil microbes are not active.