In the field of bio organic fertilizer production, the innovative 2-in-1 granulator works like a master magician, perfectly integrating mixing and granulation processes. This “Transformer”-like equipment is redefining efficiency in the organic fertilizer production line through ingenious design innovations. By combining two essential functions into a single machine, it significantly streamlines the complete organic fertilizer line, reducing space requirements and energy consumption while improving output quality.

1. Mixing System: The Perfect Symphony of Raw Materials

The mixing system conducts like an orchestra leader, ensuring harmonious blending:

Intelligent Mixing Core – The mixing shaft made of high-strength alloy steel acts like a baton, working with spiral or paddle-shaped wear-resistant blades at 20-60 rpm to achieve over 90% mixing uniformity. The 1-8 m³ mixing chamber with curved design ensures material flows as smoothly as a symphony.

Mixing Speed: Adjustable 20-60 rpm

Mixing Uniformity:>90%

2. Granulation System: The Magical Transformation Stage

The granulation system is the most magical part:

The granulation disc with adjustable tilt (30°-50°) moves like a flexible dancer, adapting to material characteristics. The stainless steel disc with wear-resistant rubber lining ensures perfect formation of every fertilizer pellet.

Multiple “transformation” options available:

- Tooth Stirring Type: High-speed rotating claws instantly agglomerate loose materials like a magician’s hands

- Roller Press Type: Strong extrusion between rollers and template creates uniform, solid pellets

The powerful 11-45kW drive system provides stable support for this “transformation show.”

3. Intelligent Control System: The Precise Production Commander

The PLC touchscreen control system acts as the equipment’s brain:

It monitors key parameters like material moisture and mixing uniformity in real-time, sounding alarms immediately when abnormalities are detected. Like an experienced production commander, it ensures every process runs at optimal condition.

The level sensor-equipped hopper and variable-frequency screw feeder achieve intelligent “on-demand” material supply. The vibration device at the discharge end ensures smooth pellet conveying.

This 2-in-1 granulator not only saves over 30% of floor space but also increases production efficiency by 50%. It’s sparking a “2-in-1 revolution” in global organic fertilizer production, making the process smarter, more efficient, and more environmentally friendly.

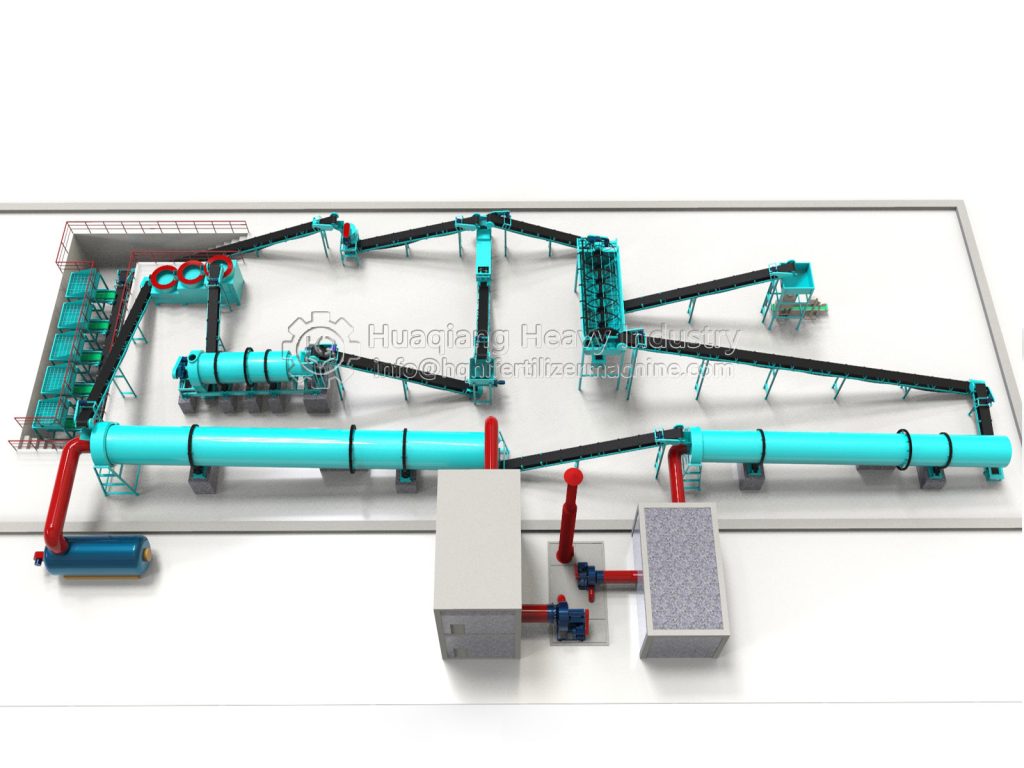

Relationship to Production Lines

The 2-in-1 granulator serves as a central component in both small-scale and industrial organic fertilizer production line setups. Its innovative design eliminates the need for separate mixing and granulation equipment, making the entire organic fertilizer line more compact and efficient. This integration is particularly valuable in bio organic fertilizer production, where precise control over the granulation process is essential for maintaining microbial viability and nutrient content.

Space Efficiency

Combines two processes into one machine, reducing the footprint of the production line by up to 40%.

Energy Savings

Uses 30% less energy compared to operating separate mixing and granulation equipment.

Process Optimization

Eliminates material transfer between machines, reducing processing time and potential contamination.