Organic Fertilizer Fermentation Time Control

Organic fertilizer fermentation time directly affects fertilizer quality and production efficiency. Typically, a complete fermentation cycle requires 25-45 days, depending on the raw material type, environmental conditions, and fermentation technology used. Under suitable temperature (55-65°C) and humidity (50-60%) conditions, using professional compost turning machines can significantly shorten fermentation time and improve efficiency.

The fermentation process is divided into three stages: temperature rise period (3-5 days), high temperature period (15-25 days), and maturation period (7-15 days). Each stage requires strict control of turning frequency and ventilation conditions to ensure optimal microbial activity.

Organic Fertilizer Machinery Price Analysis

The price of organic fertilizer production equipment varies depending on equipment type, capacity, and automation level. Basic configuration organic fertilizer turners range in price from $8,000-$50,000, while complete production line investments can reach $200,000-$1,000,000.

| Equipment Type | Price Range (USD) | Suitable Scale |

| Small Wheel Turner | 8,000-15,000 | Below 5,000 tons/year |

| Chain Plate Turner | 25,000-50,000 | 5,000-20,000 tons/year |

| Complete Production Line | 200,000-1,000,000 | Above 20,000 tons/year |

Compost Turner Selection and Comparison

Organic fertilizer turners are core equipment in the fermentation process, with main types including:

- Wheel Turners: Suitable for large-scale production with strong processing capacity

- Chain Plate Turners: Suitable for viscous materials with uniform mixing

- Groove Type Turners: Space-saving with high automation level

When selecting compost turning machines, factors such as material characteristics, production scale, site conditions, and investment budget need to be considered. Appropriate turners can not only improve fermentation efficiency but also significantly reduce labor costs and energy consumption.

Organic Fertilizer Production Line Output Optimization

The production line output of modern organic fertilizer factories depends on several factors:

- Equipment configuration and automation level

- Raw material supply stability

- Fermentation cycle control

- Production process optimization

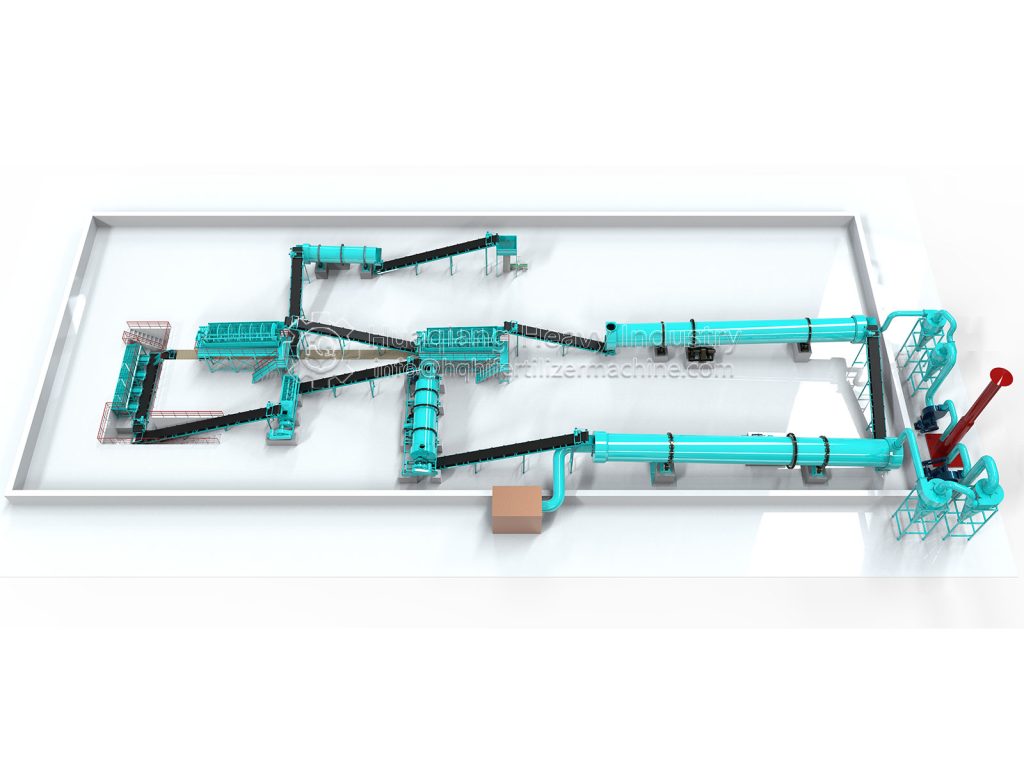

Typical production line configurations include: pretreatment system, fermentation system, crushing system, mixing system, granulation system, drying system, screening system, and packaging system. By optimizing coordination between various stages, overall output and quality can be effectively improved.

For an organic fertilizer factory with an annual output of 10,000 tons, it is recommended to configure: 2 groove type turners, 1 crusher, 1 mixer, 1 granulation system, 1 dryer, and a complete automation control system. Such configuration ensures continuous and stable production while maintaining consistent product quality.

Quality Control Key Points

To ensure organic fertilizer quality, focus on:

- Accuracy of raw material ratios

- Real-time monitoring of fermentation temperature

- Scientific control of turning frequency

- Moisture and nutrient testing of finished products

- Sanitation management of production environment

By establishing a comprehensive quality management system combined with advanced testing equipment, produced organic fertilizer can meet relevant standards and requirements, providing quality product support for sustainable agricultural development.

Advanced Quality Control in Organic Fertilizer Production

Building upon these quality control fundamentals, the entire organic fertilizer production line requires integrated equipment coordination to maintain standards. The organic fertilizer fermentation process relies heavily on proper fermentation composting technology for organic fertilizer, where equipment like the large wheel compost turner and chain compost turner (also known as wheel compost turner) ensures optimal aeration and temperature distribution. These turning machines work in sequence with the organic fertilizer granulator systems, where various organic fertilizer granulation processes transform the fermented material into uniform pellets. The fertilizer granulator stage becomes particularly critical for product consistency, as it must maintain the nutritional integrity achieved during fermentation while creating market-ready products. This seamless integration from composting to granulation represents the pinnacle of modern organic fertilizer manufacturing, ensuring every batch meets the highest quality standards for sustainable agriculture.