In modern organic fertilizer production, the application of auxiliary sterilization technologies has become increasingly important to ensure the safety and quality of final products. Beyond primary aerobic and anaerobic fermentation processes, these supplementary methods can further enhance the sterilization level of fertilizers, particularly suitable for agricultural production scenarios with strict hygiene standards.

Physical Sterilization: Rapid and Efficient Pretreatment

Physical sterilization methods primarily use thermal energy and radiation to quickly eliminate harmful organisms. Among these, high-temperature drying is one of the most commonly used techniques. By heating manure to above 100°C, it effectively destroys pathogenic microorganisms while removing moisture. This method is particularly suitable for treating raw materials with high moisture content, achieving significant sterilization effects in a short time.

Ultraviolet irradiation is mainly applied to powdered materials after fermentation, using specific wavelengths of UV light to damage microbial DNA structures for surface sterilization. Microwave treatment utilizes unique thermal effects to rapidly penetrate materials and uniformly eliminate harmful organisms throughout. These physical methods are typically used as pretreatment steps before aerobic or anaerobic fermentation, or for secondary sterilization before packaging finished fertilizers, making them especially applicable to high-hygiene production scenarios like organic vegetable cultivation.

Chemical Conditioning: Precise Control of Fermentation Environment

Chemical conditioning involves adding specific chemical agents during the fermentation process to regulate material properties and assist in degrading harmful substances. Quicklime is one of the most common conditioning agents, capable of raising material pH to above 12, creating an environment unfavorable for pathogen survival. Calcium superphosphate serves dual functions, both reacting with ammonia to reduce nitrogen loss and decreasing heavy metal activity through chemical reactions.

Humic acid, as a natural organic acid, plays a unique role in the sterilization process. It effectively adsorbs antibiotics and heavy metal ions, preventing these harmful substances from entering the soil environment. However, special attention must be paid to dosage control when using chemical conditioning methods, as excessive use may disrupt soil pH balance or affect crop growth. Therefore, this approach is typically used in combination with biological fermentation processes rather than as a standalone sterilization method.

Value and Prospects of Integrated Applications

In practical production, the combined use of these auxiliary sterilization technologies can generate synergistic effects. For instance, physical sterilization can quickly reduce initial microbial load, creating favorable conditions for subsequent biological fermentation, while chemical conditioning optimizes the fermentation environment and improves sterilization efficiency. This multi-level, multi-angle sterilization strategy ensures the safety and stability of final fertilizer products.

With continuously rising global requirements for food safety and environmental protection, the innovation and application of auxiliary sterilization technologies will become more widespread. Future development trends focus on creating more environmentally friendly and efficient combined processes that ensure sterilization effectiveness while reducing energy consumption and costs, providing stronger technical support for sustainable agricultural development.

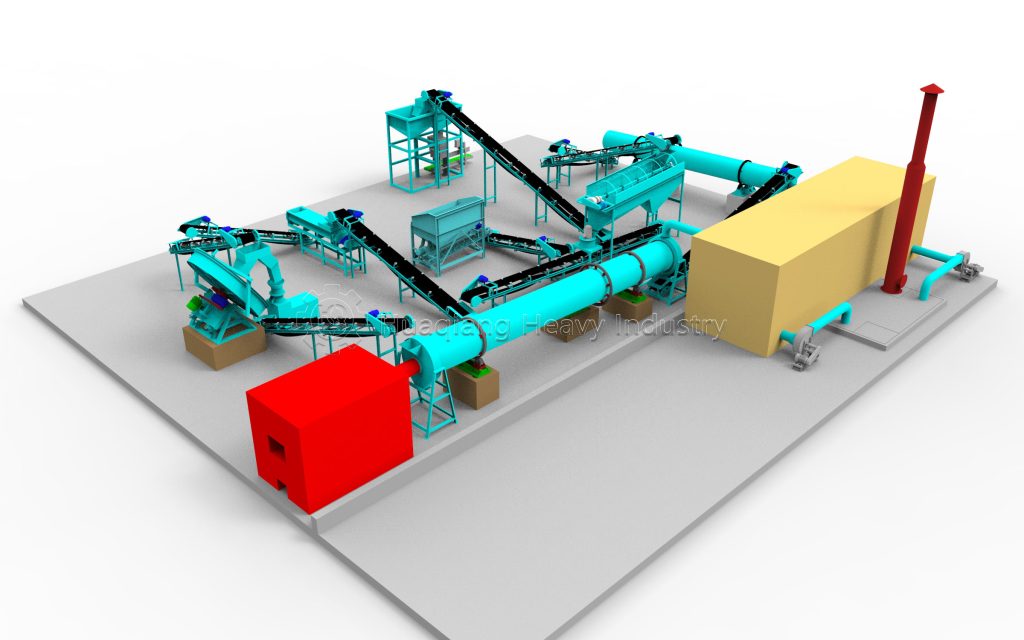

Fertilizer Sterilization and Production Integration

The integration of auxiliary sterilization technologies with modern fertilizer production represents a significant advancement in agricultural safety and efficiency. These sterilization methods complement traditional fertilizer granulation processes across various production systems. In an organic fertilizer production line, proper sterilization ensures safe inputs before materials enter the disc granulator machine for shaping. Similarly, in a bio organic fertilizer production line, sterilization maintains microbial purity while preserving beneficial organisms. The npk fertilizer production line also benefits from these technologies, where the npk blending machine combines sterilized organic components with mineral nutrients before granulation. Equipment choices like the disc granulator in a disc granulation production line or the double roller press granulator as an alternative fertilizer granulator ensure proper formation of sterilized materials. Meanwhile, windrow composting machine technology integrates sterilization directly into the decomposition phase. This holistic approach to fertilizer manufacturing – combining advanced sterilization with optimized npk fertilizer line operations and appropriate windrow machine management – creates safer, higher-quality products that meet increasingly stringent agricultural standards while supporting sustainable farming practices worldwide.