Fundamental Conceptual Differences

In the field of particle manufacturing, agglomeration and granulation are two closely related but fundamentally different concepts. Agglomeration refers to the physicochemical process where dispersed powder particles gather together to form aggregates under the action of binding forces or external forces, while granulation is a complete systematic engineering process aimed at producing qualified granular products. Simply put, agglomeration is the core part of granulation, but granulation encompasses much more than just agglomeration.

Agglomeration solves the problem of “from dispersion to aggregation,” while granulation solves the problem of “from raw materials to qualified products.” This distinction determines their different positions and values in industrial applications.

Differences in Scope and Objectives

As a single process, agglomeration has a relatively narrow scope, mainly focusing on how particles transition from a dispersed state to an aggregated state. This process may produce loose aggregates of varying sizes and insufficient strength, which often cannot be directly used as products. In contrast, granulation is a complete process flow that includes multiple procedures besides agglomeration, such as pretreatment, solidification, shaping, and screening.

Illustrative Analogy

If granulation is compared to building a complete house, then agglomeration is like constructing the building’s framework. Just having a framework is insufficient – subsequent work such as wall construction, interior and exterior decoration, and quality inspection are needed to obtain a qualified house ready for occupancy. Similarly, aggregates formed merely through agglomeration require further processes like solidification and shaping to become qualified granular products.

Specific Manifestation in Compound Fertilizer Production

Taking NPK compound fertilizer drum granulation as an example, the relationship between agglomeration and granulation becomes clear. In the drum granulator, urea powder, monoammonium phosphate powder, and potassium chloride powder gather together under the action of binders to form moist granular aggregates – this is the agglomeration process. However, these moist particles have high moisture content and low strength and cannot serve as final products.

Complete Granulation Process

The moist particles after agglomeration need to enter a dryer where excess moisture is removed under hot air at 120-150°C, solidifying the particle structure and enhancing strength. Subsequently, qualified particles are separated through screening machines, eliminating undersized or oversized unqualified products. The final compound fertilizer particles of 2-4 millimeters with qualified compressive strength represent the complete product of the granulation process.

Industrial Significance and Application Value

As a fundamental process, agglomeration can occur naturally in various scenarios, such as powdered fertilizers absorbing moisture and caking in humid environments. However, such naturally occurring agglomeration is often purposeless, producing aggregates of unstable quality. In contrast, agglomeration in industrial granulation is precisely controlled and optimized, aiming to establish a foundation for subsequent processes.

The core value of granulation lies in transforming powdery raw materials that are difficult to use directly into granular products that are convenient for transportation, storage, and use through systematic process flows. This not only improves the physical properties of materials but also enhances product utilization efficiency and commercial value.

Understanding the difference between agglomeration and granulation helps in selecting appropriate technical routes in industrial production, optimizing process parameters, and ultimately producing high-quality granular products that meet requirements. This understanding holds significant guiding importance for particle manufacturing in multiple fields including fertilizers, pharmaceuticals, and chemicals.

Integrating Agglomeration Principles into Modern Fertilizer Production Systems

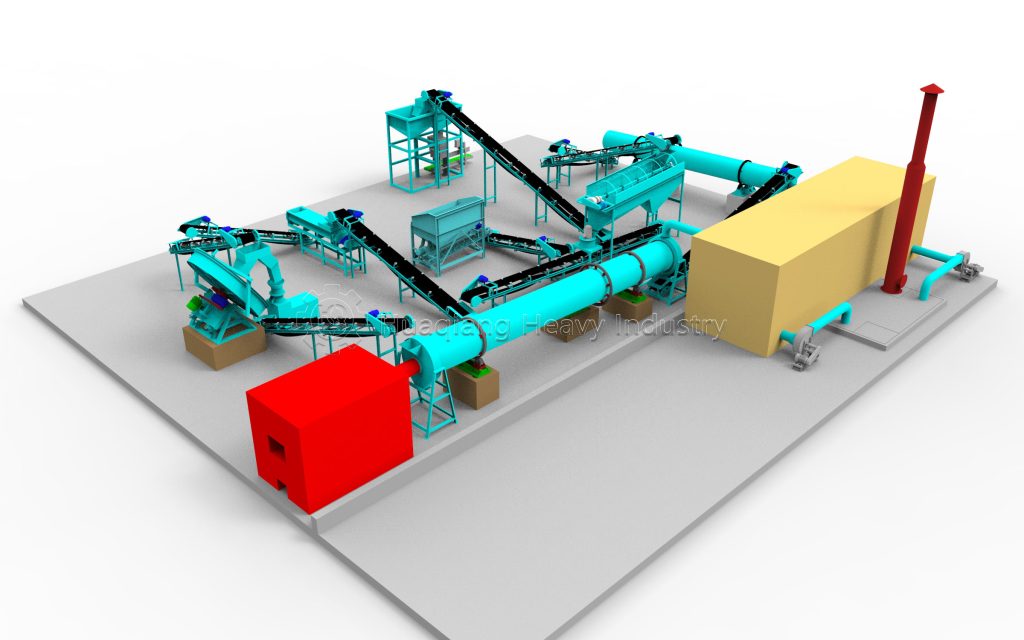

The fundamental distinction between agglomeration and granulation becomes particularly evident when examining complete fertilizer granulation processes in industrial settings. Modern npk fertilizer production line configurations carefully orchestrate both the initial agglomeration phase and subsequent processing stages to create high-quality granular products. Equipment like the disc granulator machine and double roller press granulator exemplify how controlled agglomeration serves as the foundation for producing uniform, durable fertilizer granules through different technical approaches.

In organic fertilizer production line systems, the relationship between agglomeration and complete granulation is equally crucial. Following the decomposition phase facilitated by windrow composting machine equipment, materials undergo precise agglomeration in disc granulator units before proceeding through drying and screening operations. Similarly, bio organic fertilizer production line setups must balance microbial considerations with physical granulation requirements to maintain both biological efficacy and product physical quality.

The comprehensive roller press granulator production line demonstrates how modern fertilizer equipment integrates agglomeration principles with complete processing capabilities. From basic npk blending machine operations to sophisticated disc granulation production line configurations, understanding the distinction between simple particle aggregation and systematic granulation enables manufacturers to optimize their fertilizer granulator selection and process parameters for specific product requirements across different npk fertilizer line applications.