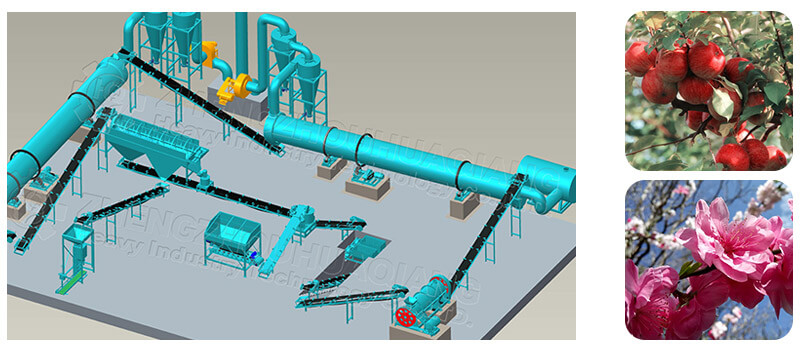

Different types of organic fertilizer equipment to meet market demand

Organic fertilizer equipment uses its own strength as a weapon against market competition. When facing problems, it will use its own strength to solve the problem and help organic fertilizer equipment become stronger. This shows the importance of strength for organic fertilizer equipment. After a long-term development of organic fertilizer equipment, we have accumulated rich experience and have a deeper and clearer understanding of the market development trend. During the long and arduous growth process, we continue to learn the current international. The most selected technology on the market to meet market demand, provide the market with the most satisfactory organic fertilizer as a development goal, and constantly transform organic fertilizer equipment.

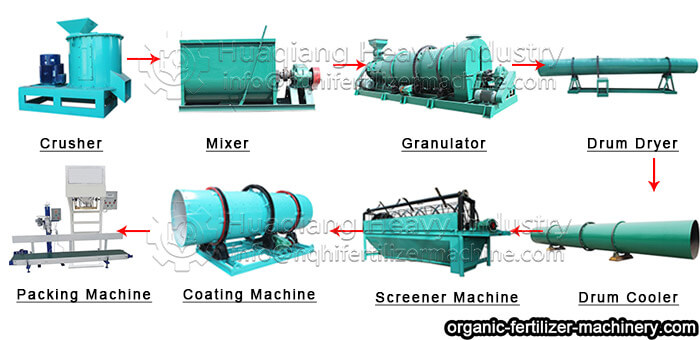

Fertilizer granulator machine series are to be designed fertilizer can be made into granulator and powder.Different type fertilizer are to be designed in different type fertilizer manufacturing process.The organic fertilizer granulator machine are to be designed and used to finish the granulation process,so the fertilizer granulator machine are to be designed and used to finish the production process.There we share more information about the fertilizer granulator machine type.

The fertilizer granulator machine also included the flat die granulator machine,new type organic fertilizer machine,and roller press granulator machine to be deisnged and used.Some other organic fertilizer machine or other series fertilizer machines are to be designed for different type.

Zhengzhou Huaqiang is willing to provide you with professional solutions and the most favorable fertilizer granulator machine price.