Bio fertilizer production

The bio fertilizer production line is designed and used to produce the bio organic fertilizer granulator.In this fertilizer manufacturing process,it is equipped with different type fertilizer machines.So how to produce the bio organic fertilizer granulator?

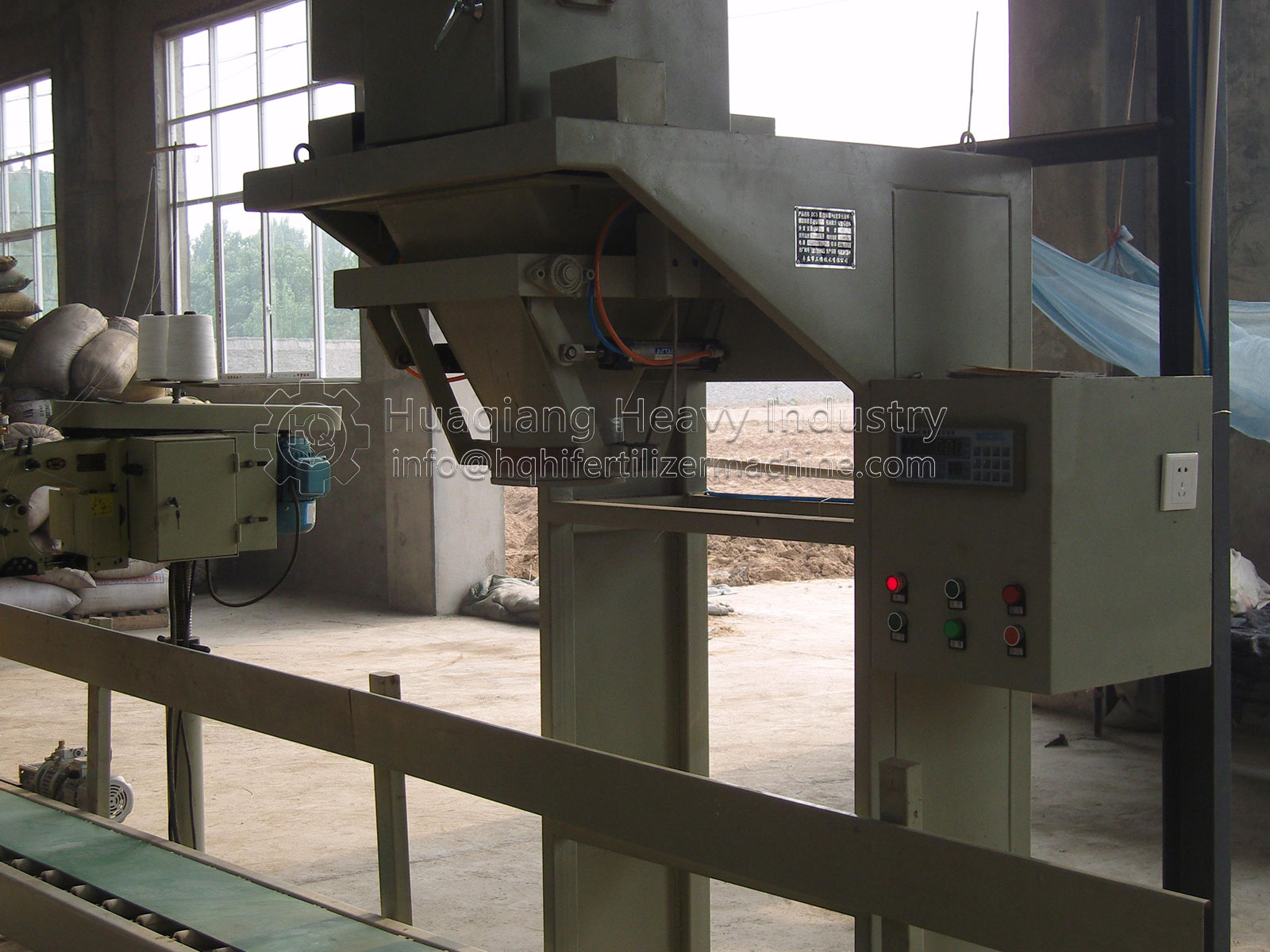

When producing the bio fertilizer granulator using the fertilizer equipment,we are first to use the fermentation compost turner machine to ferment the bio organic raw materials,which it is usually is the chicken manure,straw manure and sludge and so on.Using the fermentation compost turner machine purpose is to use the fermenting technology to kill the bacterial in the raw materials,generally it needs 7-10 days to ferment the raw materials.And then put them into the fertilizer crusher machine to grind the raw materials to the powder.And put them into the half wet materials crusher to make them mixed with other additional materials.Next to use the fertilizer granulator machine to make the granulator.The fertilizer granulator machines are the factor equipment when producing the fertilizer into granulator.Because different type fertilizer granulator machines are designed for different producing method.Such as the roller press granualtor machine is suitable the extrusion method to produce the fertilizer granulator,which this type fertilizer granulator machine is usually equipped in the npk fertilizer manufacturing process to produce the npk fertilizer granulator.Because the bio organic fertilizer granulator is also a kind of organic fertilizer granulator,we also can use the disc granulator machine to produce the bio organic fertilizer.Besides the disc granualtor machine can be choosen,the new type organic fertilizer granulator,rotary drum granulator and flat die granulator machine also can be used to produce the organic fertilizer granulator.After granulating,we need to use the fertilizer screener machine to separate thee qualified granulator from the inqualified granulator.And put the qualified granulator into the packing machine to be packed.And put the inqualified the granulator into the chain crusher machine to be grined again and make into granulator again.The designing in most large extent reduce the waste of the raw materials,and improve the working efficient.

The complete fertilizer production line is designed for producing the fertilizer granulator using the fertilizer manfuacturing technology simplify the producing process and save the time of the producing.Moreover,it also reduces the labor investment in this fertilizer manufacturing process using the smi-automatic machines to finish the fertilizer production process.