The advantages and production process of organic fertilizer granulator in processing fertilizers

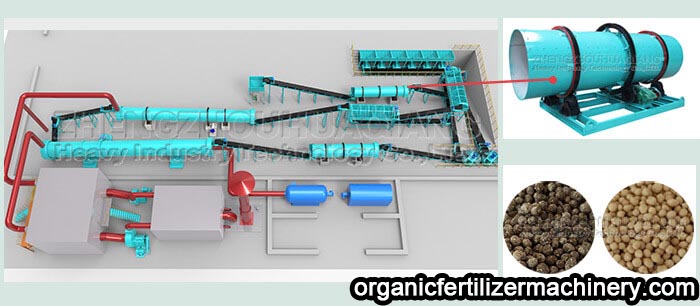

Organic fertilizer granulator includes flat mold organic fertilizer granulator, ring mold organic fertilizer granulator, double roller organic fertilizer granulator, hammer type organic fertilizer granulator, disc type organic fertilizer granulator, drum type organic fertilizer granulator Fertilizer granulator, drum type organic fertilizer granulator, etc., almost include all organic fertilizer granulators except tower granulation and condensation granulation, covering the common organic fertilizer granulation in the industry equipment. In fact, organic fertilizer powder is the best suitable fertilizer for crops. This kind of fertilizer has a simple production process, low processing cost, less harmful ingredients, and fast absorption by crops. However, with the popularization of mechanized fertilization and the existence of powder transportation People are slowly approaching organic fertilizer granulation because of the disadvantages of this. Therefore, the organic fertilizer granulator was born.The traditional organic fertilizer granulator is a disc-type organic fertilizer granulator, a drum-type organic fertilizer granulator, and a drum-type organic fertilizer granulator. These equipment play the role of connecting the past and the future for the later organic fertilizer machine. It has made great contributions to the accumulation of experience in organic fertilizer granulators. The advantages of disc granulator, drum granulator and drum type organic fertilizer granulator are simple process, convenient operation, less equipment failure and high output, but these organic fertilizer granulators have high moisture content in the finished granules. , Small particle density, high bagging rate of broken, high dust content during processing, uneven particle size and other defects. Through these defects, people gradually carried out equipment transformation and renewal.

The common organic fertilizer granulator on the market now is a combination of a flat die organic fertilizer granulator and a disc-type organic fertilizer granulator. The flat mold organic fertilizer granulator has the characteristics of high pressure, easy adjustment of the gap of the mold pressing wheel, high density of pressed particles, low dust content in the working environment, low particle moisture content, and easy drying of the finished product. The granulator can only compress columnar granules and is almost powerless for machine-seeded spherical granules. Combining the flat mold organic fertilizer granulator and the disc-type organic fertilizer granulator can reflect the superiority of the production of organic fertilizer particles, especially spherical particles. The basic use process is to use the rotation of the disc organic fertilizer granulator to polish and polish the columnar particles extruded by the flat-die organic fertilizer granulator, and finally produce spherical organic fertilizer particles. Different fertilizer granulators are selected for different fertilizer production process.

.jpg)

.jpg)

.jpg)