Working principle and advantages of organic fertilizer fermentation equipment

Organic fertilizer fermentation equipment is the first choice of organic fertilizer production enterprises, because it has great advantages in practicability and cost control, and is one of the better equipment combined with the operation mode of agriculture and animal husbandry. Here is a brief introduction to the working principle and advantages of this organic fertilizer production equipment.

1. Working principle of organic fertilizer fermentation equipment

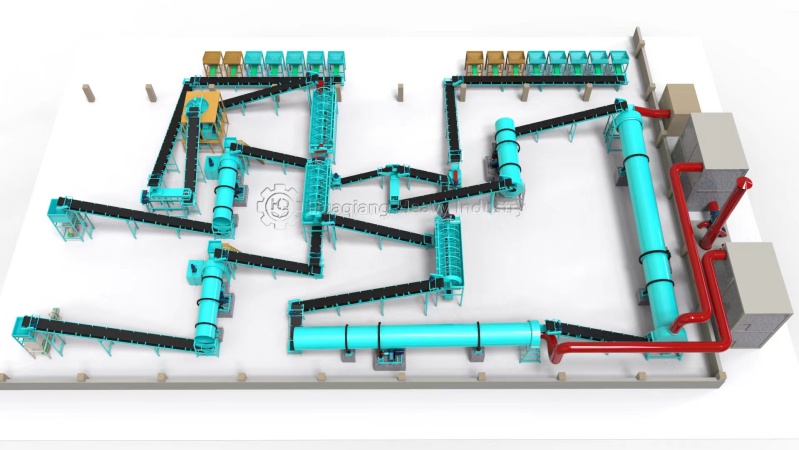

The comprehensive treatment technology of solar aerobic fermentation is adopted in compost tipper. It is composed of solar fermentation chamber, electric follow-up device, overturning and throwing machine, shifting car and aeration system. It can make full and effective use of solar energy and ferment and decompose the sewage sludge, river sludge, livestock manure and organic matter after garbage separation under the action of microorganism. The compost is further processed by an organic fertilizer granulator.

Aerobic fermentation by solar energy is a very important link in organic fertilizer production. During this period, the treatment of organic solid waste must solve the problems of drying, fermentation, sterilization, deodorization, and finally obtain higher economic benefits with lower cost. Before fermentation, various raw materials to be fermented are mixed according to a certain proportion, so as to meet the fermentation conditions such as water, carbon and nitrogen ratio, and finally achieve the purpose of shortening the fermentation cycle and achieving the best fermentation effect.

2. Advantages of organic fertilizer fermentation equipment

Compared with other similar equipment, organic fertilizer fermentation equipment has great advantages. By comparison, it is found that the windrow turner is flexible, but covers a large area; the fermentation period of fermentation tank is short, but the cost is high, and it is not suitable for popular demand. At present, the more widely used is the trough type compost turner, and the high-grade ones are double screws compost turning machine and chain compost turner, etc. there are many types of products, which can be ordered according to their own needs.

.jpg)

.jpg)