Is Bokashi Better Than Composting?

In the realm of home composting, a frequent question arises: “Is Bokashi better than traditional composting?” The answer is not a simple “yes” or “no.” Rather than viewing them as competitors, it’s more helpful to see them as complementary tools designed for different needs and scenarios. Understanding their respective strengths and limitations is key to choosing the best method for you.

Core Difference: Process and Principle

The fundamental distinction lies in their core processes:

Bokashi Composting is a two-stage anaerobic fermentation process. First, kitchen waste is mixed with inoculated bran containing Effective Microorganisms (EM) in an airtight bucket. Over about 2-4 weeks, it undergoes lactic acid fermentation, transforming into “pre-compost” and a liquid fertilizer called “Bokashi tea.” Second, this pre-compost must be buried in soil or added to a traditional compost pile for an additional 2-4 weeks of aerobic decomposition before it becomes usable compost for plants.

Traditional (Aerobic) Composting is a direct, single-stage oxidation process. Organic matter (like yard waste and vegetable peels) decomposes through the action of oxygen, moisture, and microbes, resulting directly in finished compost ready for the garden.

The Distinct Advantages of Bokashi

The Bokashi method excels in several areas, making it particularly suited to modern urban living:

Unmatched Waste Scope: It can safely and odorlessly process almost all kitchen scraps, including meat, fish, dairy, cooked foods, and bones—materials that are problematic in traditional compost—enabling true kitchen “zero waste.”

Indoor-Friendly, Clean and Fast: The entire fermentation stage occurs in a sealed bucket, producing no foul odors or attracting pests, making it ideal for apartments, kitchens, or small balconies. The initial conversion is also quicker (2-4 weeks).

Dual Outputs: Beyond the final soil amendment, it produces Bokashi tea—a valuable byproduct that, when diluted, serves as a potent liquid fertilizer or natural cleaner.

Superior Environmental Benefits: Its closed anaerobic process is more effective at minimizing greenhouse gas emissions (like methane), resulting in a lower carbon footprint compared to open-air traditional piles or landfills.

The Irreplaceable Strengths of Traditional Composting

However, traditional composting remains vital due to its simplicity and reliability:

Direct Process, One-Step Result: The compost is ready to use immediately upon completion, requiring no secondary processing. For gardeners, this is the most straightforward recycling method.

Low Cost, Easy Start-Up: It requires almost no ongoing purchase of specialized additives (like Bokashi bran) beyond a compost bin or a dedicated pile, relying primarily on naturally occurring microbes.

Excellent for Bulk “Browns”: A traditional compost pile is the most economical and effective way to handle large volumes of “brown” (carbon-rich) materials like yard trimmings, weeds, and fallen leaves.

Higher Fault Tolerance: It doesn’t demand an airtight seal. Even with less meticulous management (e.g., infrequent turning), the material will eventually break down, albeit more slowly.

How to Choose? The Key is Your “Context”

Therefore, determining which method is “better” depends entirely on your specific situation:

Choose Bokashi Composting if you: Live in an urban apartment with limited outdoor space; regularly generate mixed kitchen waste containing meat and leftovers; desire a fast, clean, indoor solution; and have a way to complete the second step (e.g., a garden bed, planter for burying, or access to a community composting system).

Choose Traditional Composting if you: Have a yard or ample outdoor space; your waste primarily consists of plant-based garden debris and fresh fruit/vegetable scraps; and you want the lowest-cost, simplest process to obtain compost.

The Best Strategy: Combining Strengths

In fact, many experienced gardeners adopt a hybrid strategy to maximize the benefits of both: Use a Bokashi bucket to process all tricky kitchen wet waste (especially animal products), then add the resulting pre-compost and Bokashi tea to a traditional compost pile. The pre-compost acts as a powerful “fermentation starter” and nitrogen source, significantly accelerating the decomposition and enhancing the fertility of the traditional pile. This approach solves the problem of sorting kitchen waste while producing large quantities of high-quality compost—a true win-win.

Bokashi composting is not an “upgraded replacement” for traditional composting but rather a powerful complementary and pre-treatment technology. It expands the boundaries of home composting, making food scrap recycling more comprehensive and convenient. By assessing your space, waste stream, and lifestyle, you might find that the best answer isn’t an either/or choice, but a clever way to let both methods work in synergy, building a more sustainable waste-cycle system together.

Conclusion: Integrating Composting Methods for Maximum Impact

Ultimately, the choice between Bokashi and traditional composting isn’t about superiority but about strategic integration. The hybrid approach—using Bokashi for kitchen waste pre-treatment followed by traditional aerobic decomposition—represents the pinnacle of home-scale fermentation composting technology for organic fertilizer. This synergistic method creates a complete waste-to-resource cycle that is both efficient and environmentally robust.

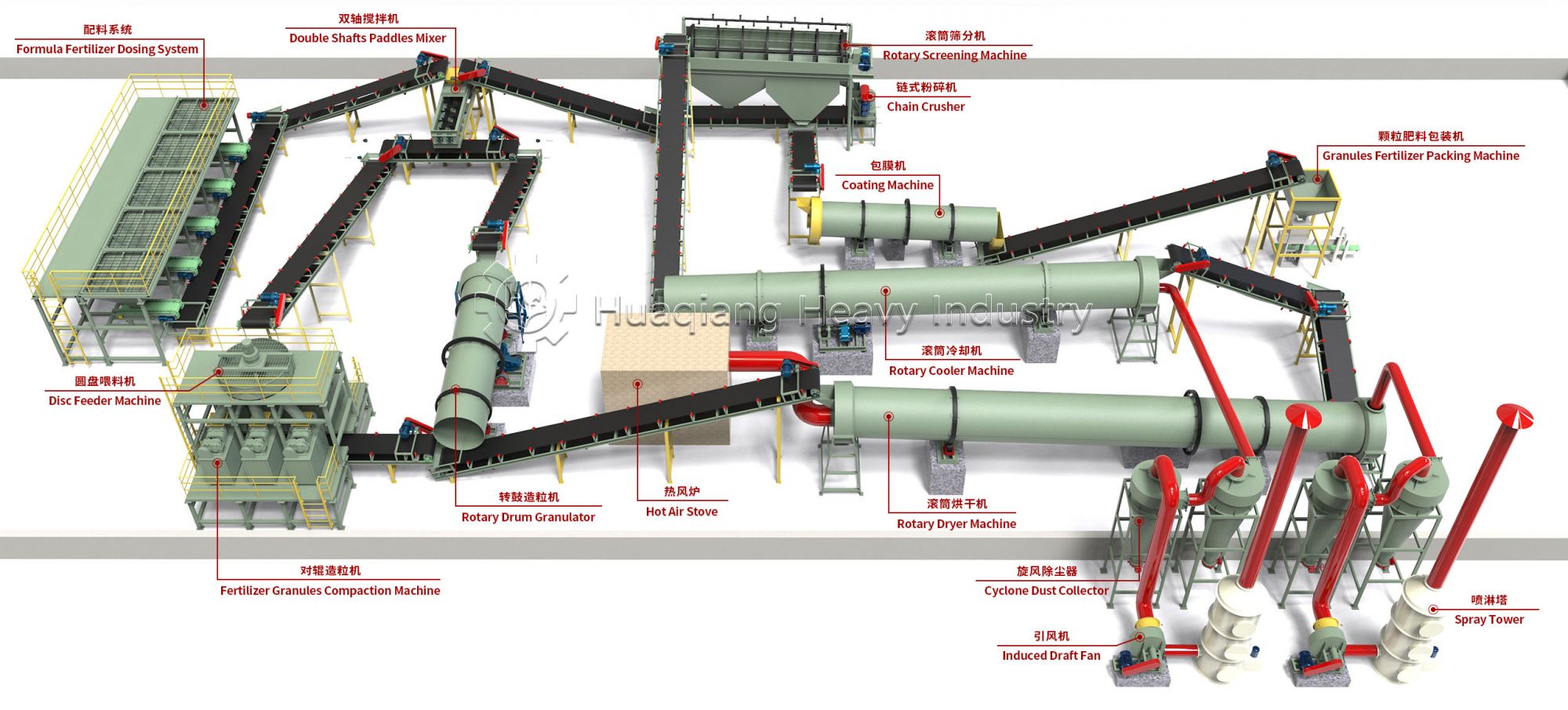

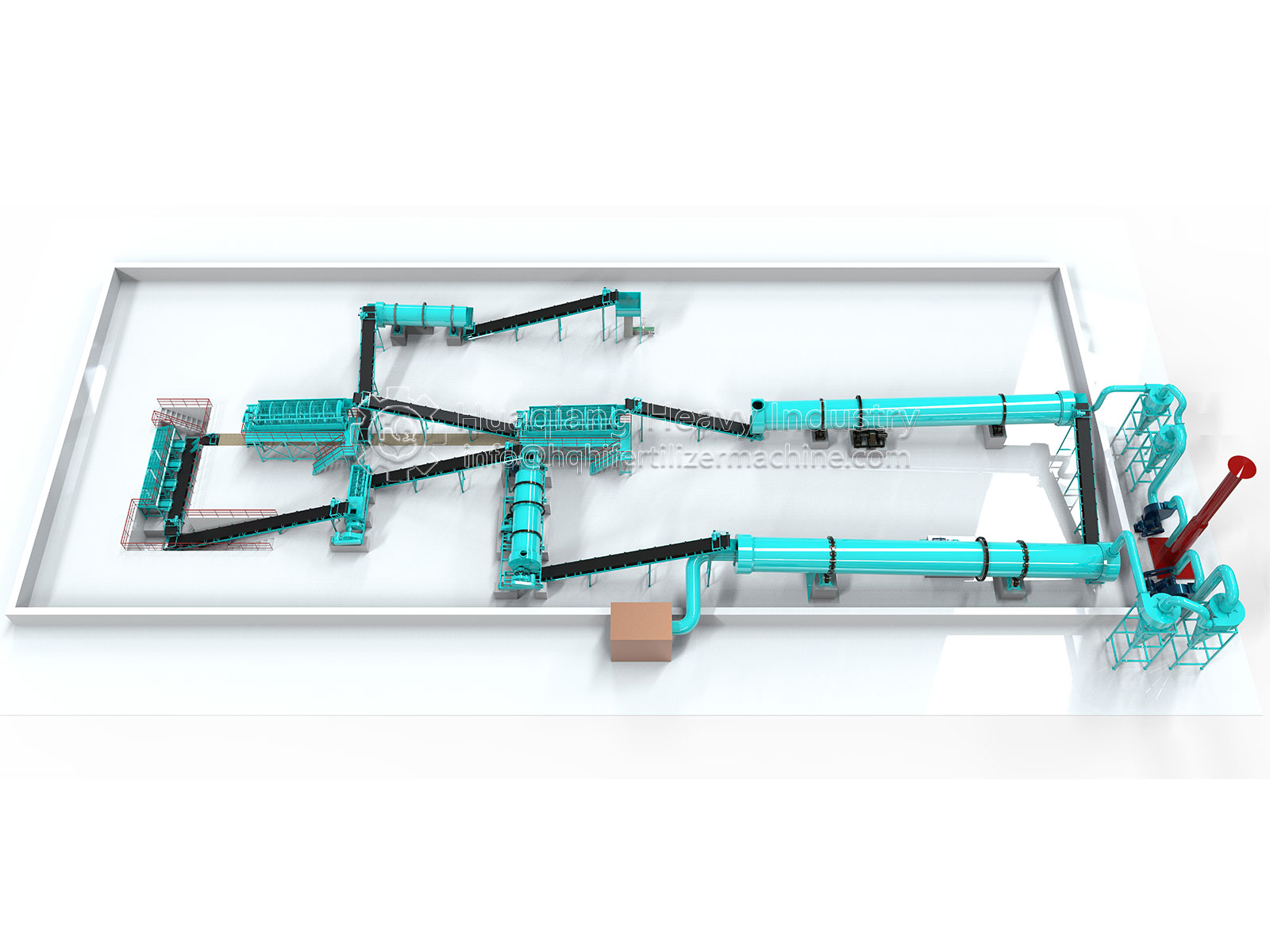

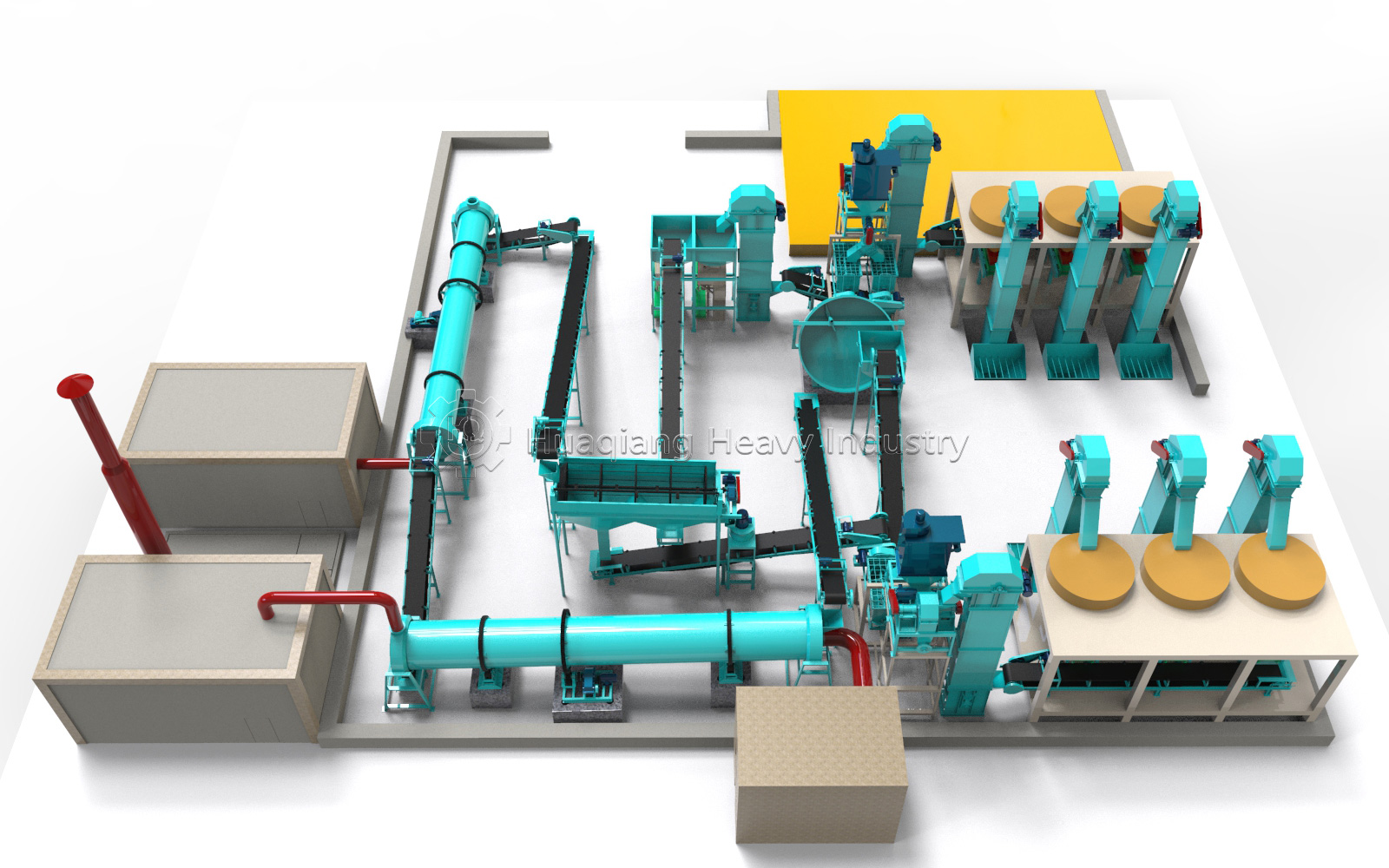

For larger-scale operations or community gardens, this integration can be enhanced with professional fertilizer making machine equipment. The pre-compost from Bokashi fermentation can be efficiently processed in a traditional windrow system using a windrow compost turner, trough-type compost turner, or large wheel compost turning machine to optimize the fermentation composting turning technology. For those looking to produce commercial organic fertilizers, the resulting compost can be further refined using a drum organic fertilizer dryer and shaped into uniform pellets with a disc granulator for shaping as part of a complete disc granulation production line.

This comprehensive approach leverages the strengths of both methods while incorporating advanced fertilizer granulation technology. Whether at home with simple buckets or at scale with industrial equipments required for biofertilizer production, the combination of anaerobic pre-treatment and aerobic finishing creates superior soil amendments, closing the nutrient loop sustainably and effectively.

Integrated Technologies: trough-type compost turner, large wheel compost turner, chain compost turner, disc granulation production line, equipments required for biofertilizer production, large wheel compost turning machine, fertilizer granulator, drum organic fertilizer dryer, fertilizer making machine, fermentation composting technology for organic fertilizer, fermentation composting turning technology, windrow compost turner, multiple silos single weigh static batching system, fertilizer granulation technology, disc granulator for shaping.