Equipment Overview

A cyclone dust collector is a dust removal device that uses centrifugal force generated by rotating airflow to separate particulate matter from the gas stream. With simple structure and low operating costs, it is widely used for gas purification in various industrial processes including cement, chemical, metallurgical, power, and food processing industries, effectively removing dust and particulate matter from flue gas.

Equipment Structure and Composition

Core Components:

- Inlet Pipe:Guides dusty gas into the collector, designed tangentially or spirally to promote airflow rotation

- Cyclone Body:Main part of the equipment, cylindrical design with smooth inner walls for generating and maintaining rotating airflow

- Cone Section:Located below the cyclone body, conical structure helps further separate and collect particulate matter

- Exhaust Pipe:Located at the top of the cyclone body for discharging purified gas

- Ash Hopper:Located at the bottom of the cone for collecting and storing separated particles

- Ash Discharge Device:Star-shaped discharge valves, screw conveyors, etc., for regular removal of particulate matter from the ash hopper

Working Principle

Dusty gas enters the cyclone dust collector through the inlet pipe and enters the cyclone cylinder tangentially or spirally, forming a high-speed rotating airflow. Under centrifugal force, heavier particles are pushed toward the cylinder wall and then fall along the wall into the ash hopper, achieving separation from the airflow. Purified gas is discharged through the central exhaust pipe. The rotating airflow continuously decelerates in the cyclone body and cone, further improving separation efficiency and ultimately achieving dust removal goals.

Equipment Advantages

Efficient Separation

High separation efficiency for larger particle sizes, effectively removing dust from industrial flue gas.

Simple Structure

No moving parts, compact structure, low maintenance costs, long service life, suitable for various industrial environments.

Reliable Operation

Easy operation, stable performance, strong adaptability, capable of handling high-temperature and high-dust-concentration gases.

Economical and Practical

Relatively low initial investment and operating costs, particularly suitable for small and medium-sized gas purification needs.

Environmentally Friendly

No secondary pollution, relatively low energy consumption, meeting modern industrial environmental requirements.

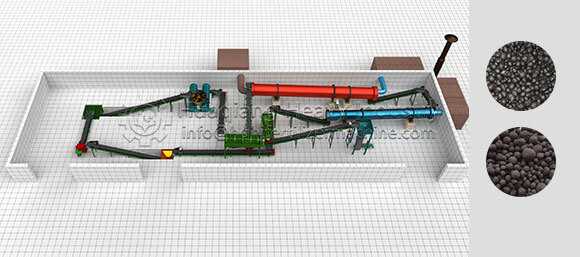

Application Value

With its unique working principle and superior performance characteristics, the cyclone dust collector plays an important role in industrial dust control across various fertilizer production facilities. It provides essential environmental protection for complete production lines including the npk fertilizer production line, organic fertilizer production line, and bio organic fertilizer production line. These systems, which incorporate equipment such as the npk blending machine, disc granulator, double roller press granulator, and windrow composting machine, generate significant dust during operation. The cyclone collector effectively controls particulate matter from the disc granulation production line and windrow machine operations, not only improving working environments and protecting employee health but also reducing atmospheric pollution to promote sustainable development. As environmental requirements continue to increase, cyclone dust collectors will remain crucial in creating cleaner production environments for the fertilizer industry, ensuring that fertilizer granulator operations meet the highest environmental standards while maintaining production efficiency.