Equipment Overview

The trough compost turner represents a cornerstone technology in modern organic processing systems, serving as specialized equipment designed for optimized fermentation processing. Through its unique reciprocating motion mechanism, this machine utilizes turning teeth on mechanical arms to thoroughly aerate materials within fermentation tanks, creating ideal conditions for microbial activity and accelerated decomposition.

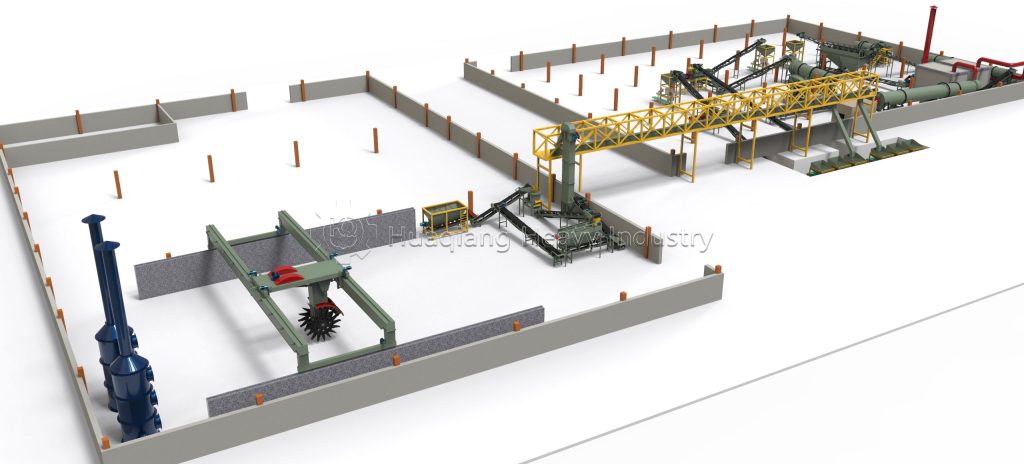

In comprehensive bio organic fertilizer production facilities, multiple equipment variants work in synergy. While the trough compost turner operates within contained channels, the large wheel compost turner offers exceptional mobility for larger-scale operations, and the chain compost turner provides robust performance for high-volume processing. These essential compost fertilizer machine solutions form the backbone of efficient organic waste transformation systems.

The complete equipments required for biofertilizer production extend beyond turning mechanisms to include specialized processing units. Following the fermentation phase, materials typically progress to a disc granulation production line, where compost is shaped into uniform granules for commercial distribution. This integrated approach ensures that organic matter undergoes complete transformation from raw material to valuable agricultural amendment.

Modern large wheel compost turning machine innovations have significantly enhanced processing efficiency, featuring adjustable working depths and automated control systems. As a crucial fertilizer production machine category, these turners facilitate critical functions including temperature regulation, moisture control, and oxygen infusion – all vital parameters for successful composting. The continuous development of compost fertilizer machine technology continues to advance sustainable agriculture practices worldwide, supporting circular economy initiatives and reducing environmental impact through efficient organic waste valorization.

Technical Advantages

Compared to traditional manual turning or ground composting methods, the trough compost turner adopts a trough structure design that enables continuous fermentation operations, greatly improves fermentation efficiency, significantly shortens the fermentation cycle, and effectively controls odor and pollution during the fermentation process, making it one of the key equipment for large-scale organic fertilizer production.

Applicable Raw Material Range

Livestock and Poultry Manure

Including chicken, pig, cow, and sheep manure, these materials are rich in organic matter and nutrients such as nitrogen, phosphorus, and potassium, making them excellent raw materials for organic fertilizer production. Through the turning action of the trough compost turner, the manure undergoes complete fermentation, eliminating pathogens, insect eggs, and weed seeds while removing odors.

Crop Straw

Corn straw, wheat straw, rice straw, etc., contain large amounts of cellulose, hemicellulose, and lignin, which can be converted into organic matter in organic fertilizer through fermentation. The trough compost turner can evenly mix straw with other raw materials to promote straw decomposition and maturation.

Edible Mushroom Residue

Mushroom cultivation residue rich in mycelium and underutilized nutrients serves as high-quality organic fermentation raw material. After processing in the compost turner, it can be made into highly effective organic fertilizer.

Industrial Organic Waste

Including organic by-products from industrial production processes such as distiller’s grains, vinegar residue, sugar residue, and oil residue. These wastes contain certain organic matter and nutrients and can be recycled after fermentation in a trough compost turner.

Municipal Sludge

Sludge generated by municipal sewage treatment plants contains substantial organic matter but may also contain harmful substances like heavy metals. It must undergo rigorous testing and treatment before being used as fermentation raw material. The trough compost turner can thoroughly ferment the sludge, reduce its moisture content, and stabilize its properties.

Environmental Benefits

The widespread application of trough compost turners not only improves the efficiency of organic waste treatment but also enables resource recycling. Through scientific fermentation processing, various organic wastes are transformed from waste to valuable resources, reducing environmental pollution while providing high-quality organic fertilizer for agricultural production, aligning with sustainable development principles.