Turning Pig Manure into Treasure: Bio-organic Fertilizer Innovation

Environmental Challenges in Livestock Development

With the global scale development of animal husbandry, the treatment of large amounts of pig manure has become a serious environmental issue. Traditional composting methods suffer from long cycles, significant nutrient loss, and improper carbon-to-nitrogen ratios, resulting in low efficiency and atmospheric pollution.

Innovative Solution

The new bio-organic fertilizer technology effectively addresses the shortcomings of traditional composting by adding efficient microbial agents and optimizing formulations. This technology uses scientific microbial combinations to significantly improve composting efficiency and quality.

Core Technical Formula

· Fermented pig manure: 65-85 parts by weight

· Conventional additives: 5-10 parts

· Compound microbial agent: 3-5 parts

· Binder: 1-10 parts

Optimal formula: 80 parts fermented pig manure, 8 parts conventional additives, 4 parts compound microbes, 8 parts binder

Microbial Ratio Innovation

The compound microbes consist of yeast and rhizobium in a ratio of 3:1 to 1:1, with the optimal ratio being 2:1. The preferred yeast is Candida, while rhizobium includes peanut rhizobium or pea rhizobium, with strain concentrations of 10⁴cfu/mg.

Outstanding Product Characteristics

· Moisture content: <30%

· Organic matter content: >30%

· NPK nutrients: 25-30g/kg

· pH value: 7.5-8.0

· Parasitic egg mortality: >95%

· Colony count: <100 CFU/kg

Global Environmental Significance

This technology not only solves the problem of livestock manure pollution but also provides high-quality fertilizer for organic agriculture. Through microbial action, waste is transformed into valuable resources, achieving sustainable development in circular agriculture, which is of great significance for global environmental protection and food security.

Conclusion

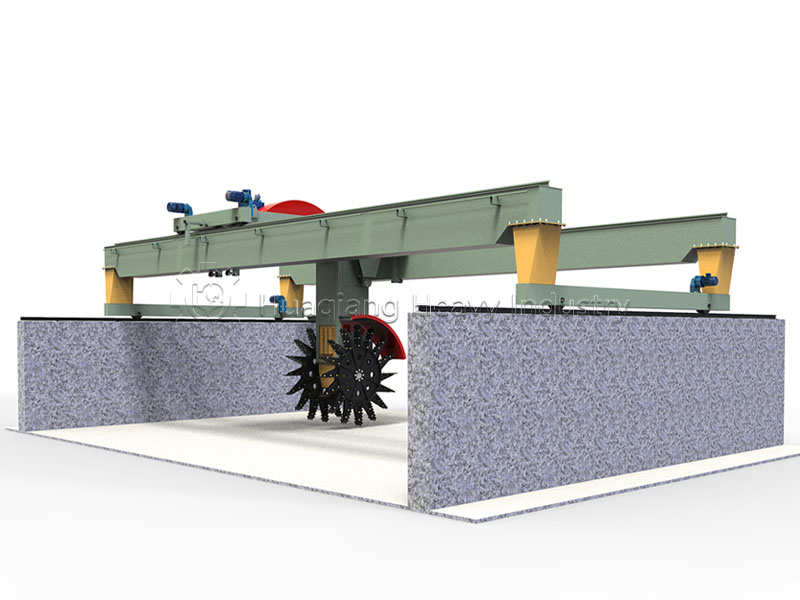

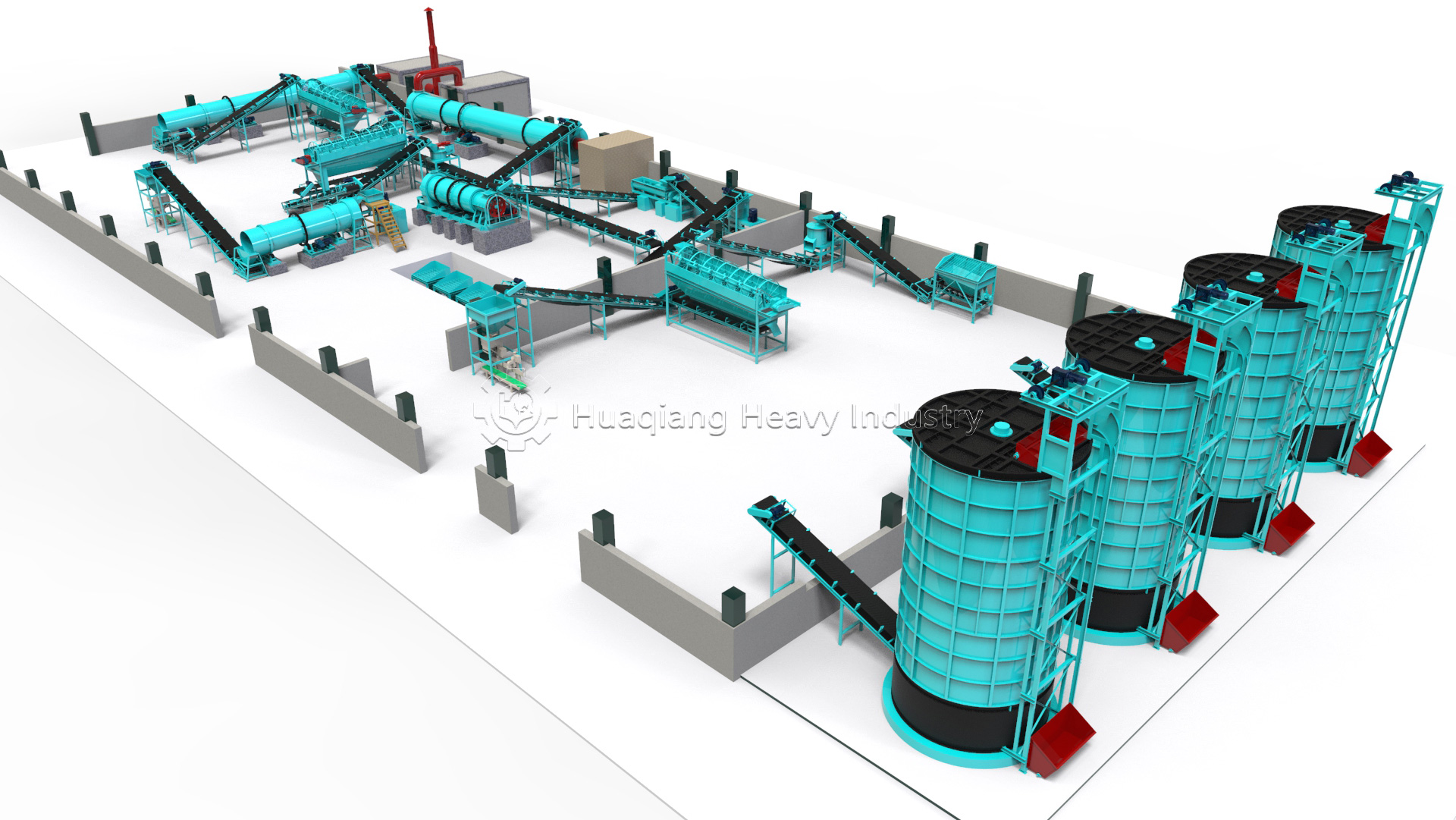

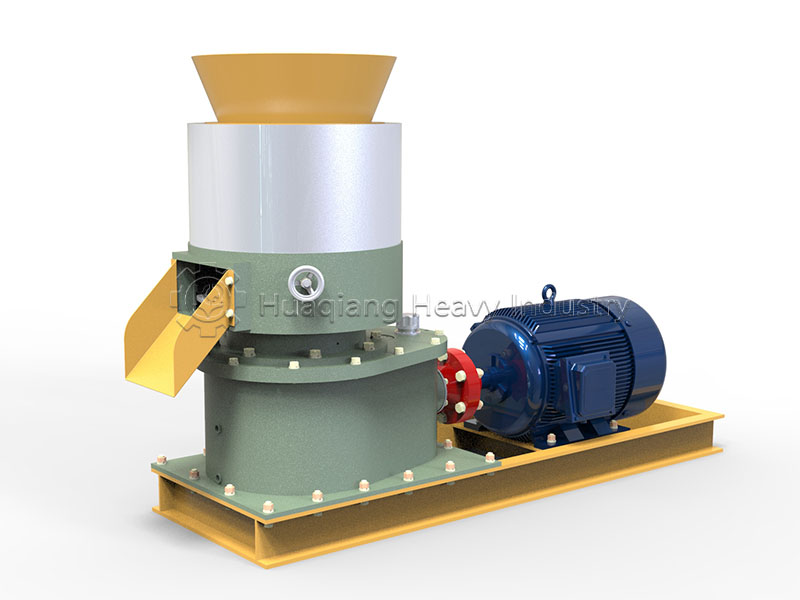

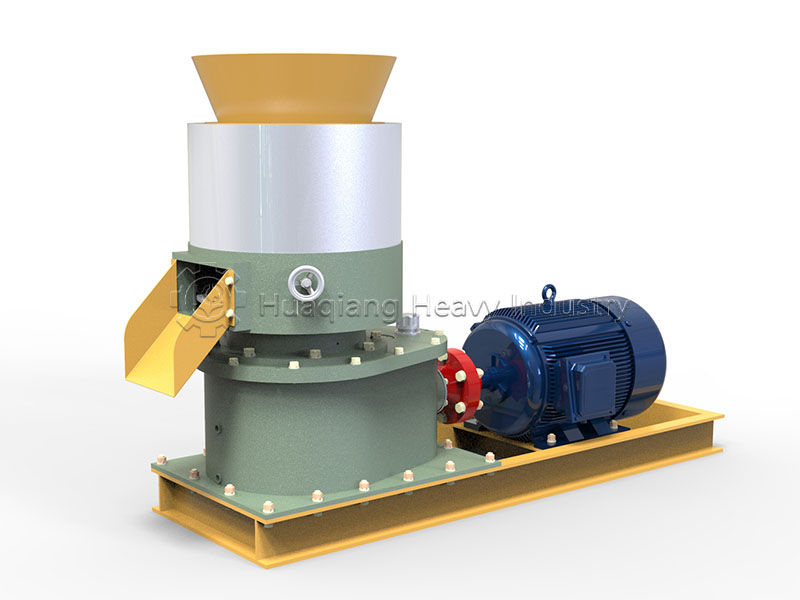

In conclusion, this innovative bio-organic fertilizer technology represents a paradigm shift in sustainable agriculture by transforming environmental challenges into valuable opportunities. The integration of specialized equipment such as the rotary drum granulator and new type two in one organic fertilizer granulator ensures efficient fertilizer granules compaction while maintaining nutrient integrity. The complete fertilizer production machine ecosystem—including the fertilizer compaction machine, chain compost turning machine, and roller press granulator production line—forms a seamless production chain that optimizes the equipments required for biofertilizer production. The drum granulator and rotary granulator work synergistically with microbial agents to create uniform granules with enhanced soil amendment properties. This holistic approach, combining advanced fertilizer compactor technology with biological innovation, not only resolves livestock pollution but establishes a circular economy model where waste becomes wealth. Ultimately, this system demonstrates how technological integration can simultaneously address environmental protection, agricultural productivity, and resource sustainability on a global scale.

.jpg)