On the stage of modern agriculture, NPK compound fertilizer has become a “nutrition master” for crop growth with its precise nutrient ratio and efficient fertilizer effect. But have you ever wondered how these uniform, plump fertilizer particles undergo their magnificent transformation from raw powder?

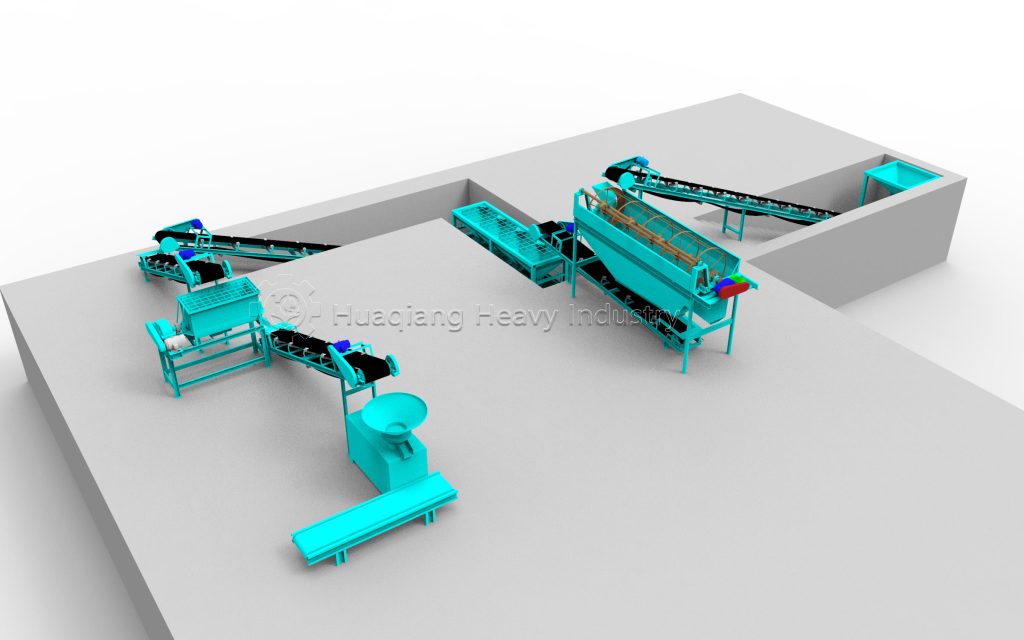

The journey begins with the sophisticated NPK fertilizer production line, where raw materials are precisely blended using an advanced NPK blending machine to create the perfect nutrient balance. This comprehensive NPK fertilizer line integrates both chemical and organic components, sometimes even connecting with an organic fertilizer production line for enhanced soil benefits.

The transformation truly begins in the granulation phase, where specialized granulation equipment takes center stage. The versatile fertilizer granulator, particularly the efficient disc granulator, works its magic in the disc granulation production line. Through a fascinating process of agglomeration, raw powder is transformed into those uniform, plump fertilizer particles that farmers depend on for optimal crop nutrition.

Let’s explore this fascinating journey of NPK compound fertilizer manufacturing, where science and technology collaborate to create the essential nutrients that feed our world.

The Symphony of Precision Production

The production process of NPK compound fertilizer is like a carefully orchestrated symphony, with each step working in harmony to ultimately create a bountiful harvest. The entire process transforms powdered raw materials into uniform granules, making it particularly suitable for producing high-nitrogen products such as organic-inorganic compound fertilizers.

Imagine various basic fertilizer raw materials undergoing meticulous screening and crushing, much like musicians tuning their instruments in preparation for perfect harmony. These materials are then precisely measured and, according to scientific ratio requirements, systematically enter the mixing hopper through conveying and lifting equipment.

The Five-Step Granulation Magic

Fine Preparation

Each basic fertilizer is separately screened, with raw materials crushed and screened again to ensure particle uniformity. Screened materials are fed into corresponding hoppers, laying the foundation for precise proportioning.

Precise Proportioning

Through metering equipment, the feeding ratio of various basic fertilizers is precisely controlled, while recycled materials also enter the feeding hopper together with basic fertilizers through lifting devices, achieving resource recycling.

Moist Granulation

In the rotary drum granulator, the clever use of saturated steam not only raises material temperature but also moderately moistens it. When necessary, small amounts of water or fertilizer solution are added to maintain optimal granulation liquid phase conditions.

Rotational Forming

Utilizing friction generated by drum rotation, squeezing forces between material particles cause them to aggregate into balls. As the drum rotates, particles gradually roll toward the outlet along the inclined direction of the cylinder.

Refined Finished Product

After leaving the granulator, particles undergo drying, screening, cooling and other processes, ultimately being packaged and stored. Unqualified particles are crushed and returned as recycled materials for reprocessing.

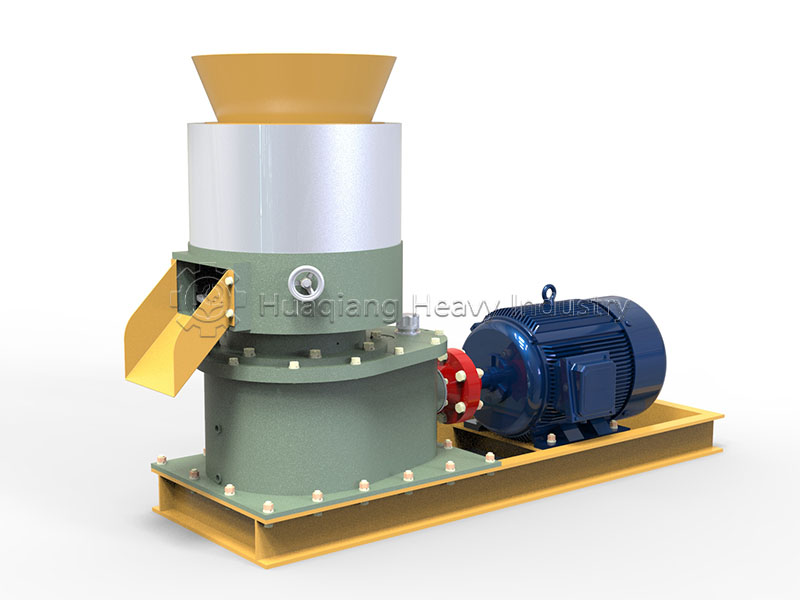

Granulator: The Core Engine of Production

As key equipment in NPK fertilizer production, the rotary drum granulator employs wet granulation technology, demonstrating the sophistication of engineering. Its cylinder uses special rubber sheet lining or acid-resistant stainless steel lining to ensure equipment durability.

During granulation, auxiliary materials such as steam, gas ammonia, or added phosphoric acid and nitrogen solutions enable heated compound fertilizer granulation. This design not only improves production efficiency but also ensures product quality stability.

.jpg)