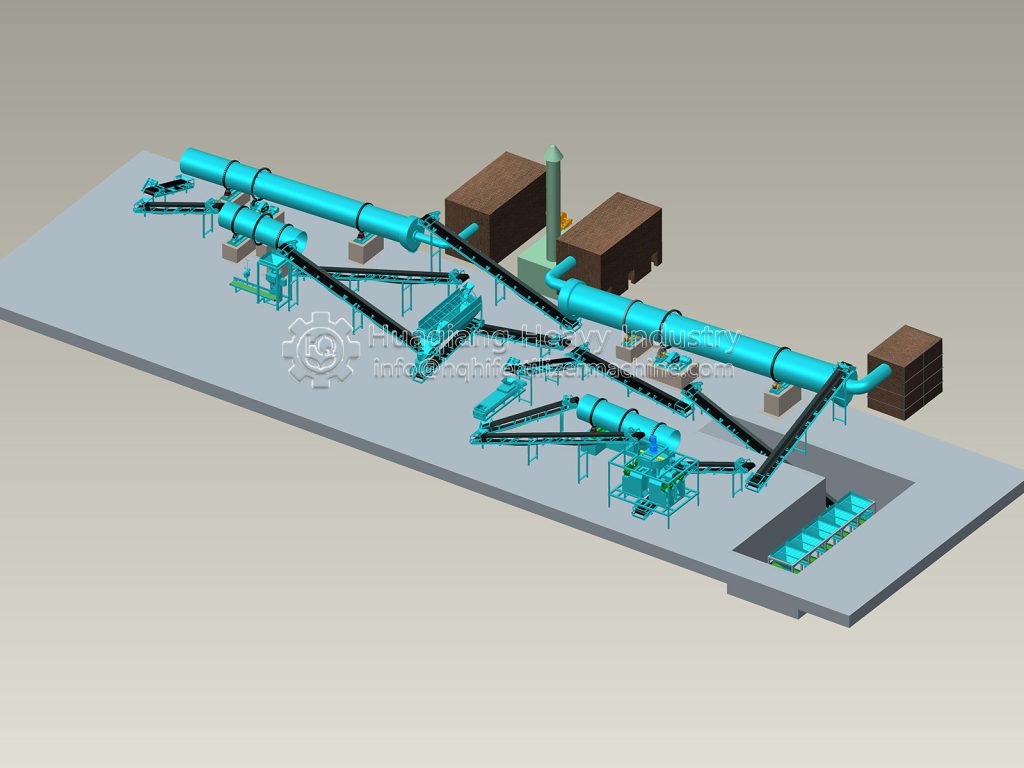

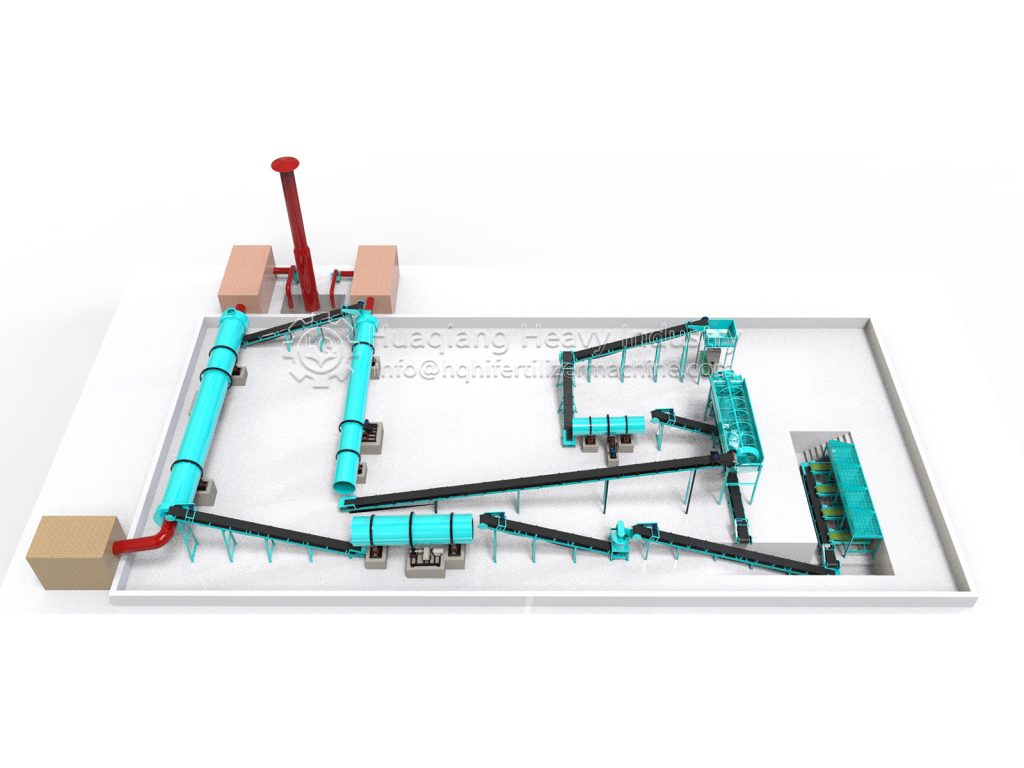

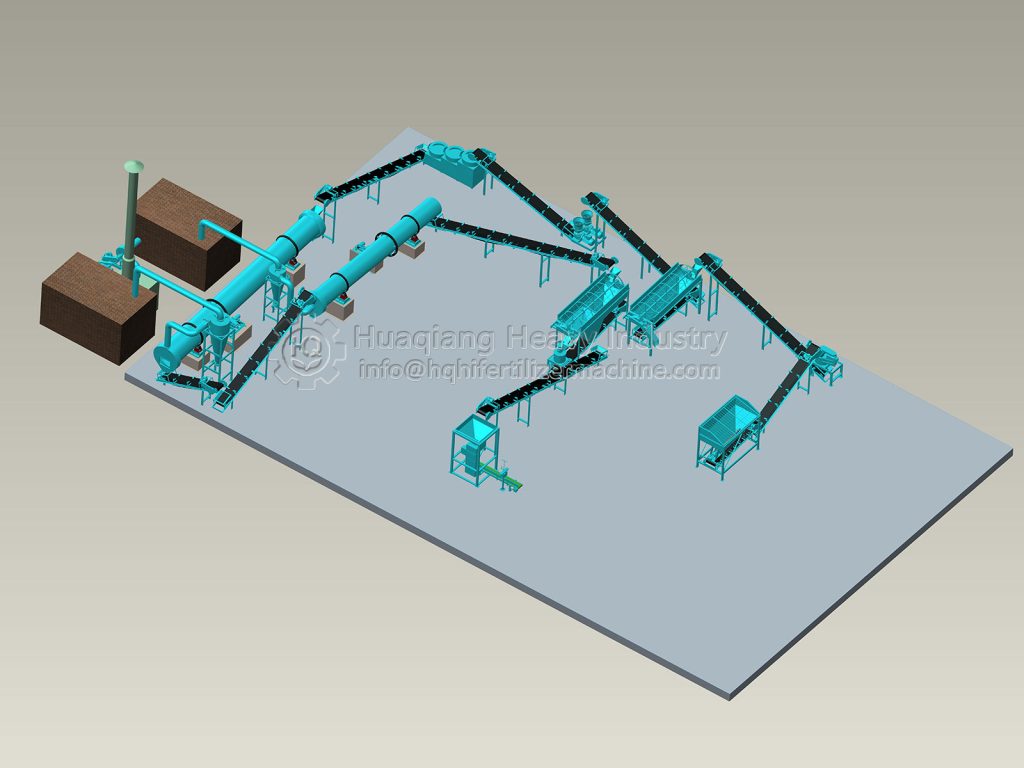

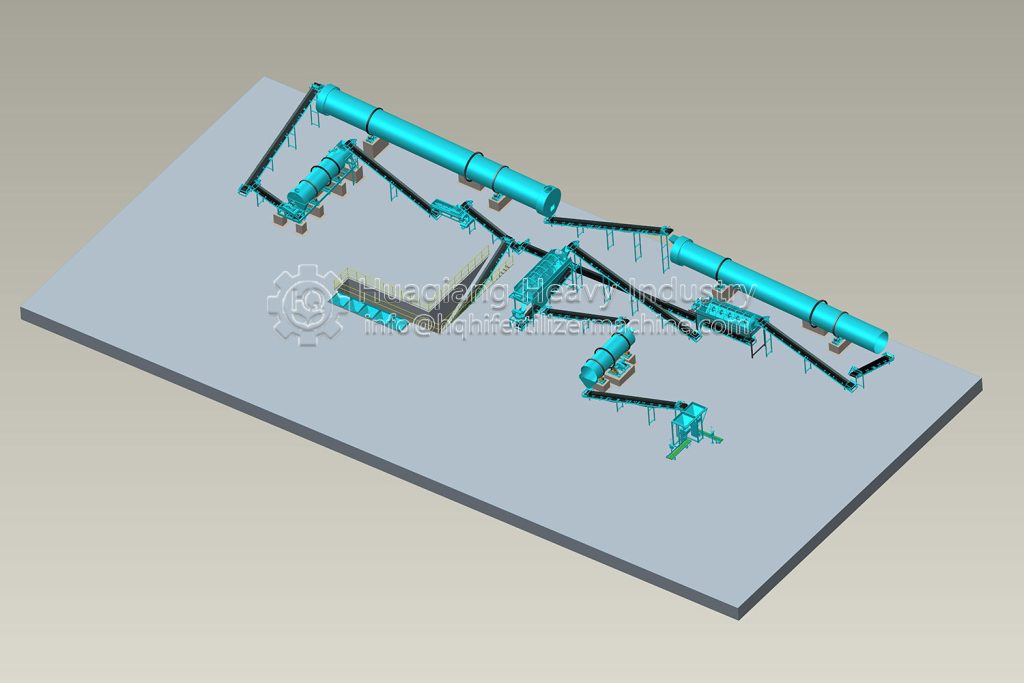

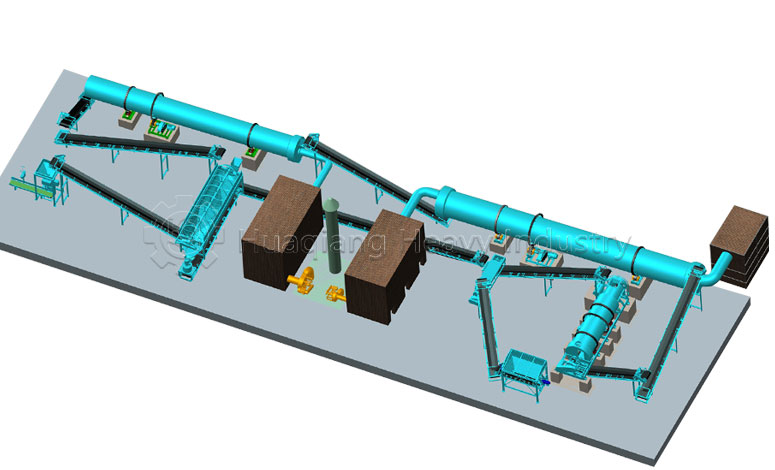

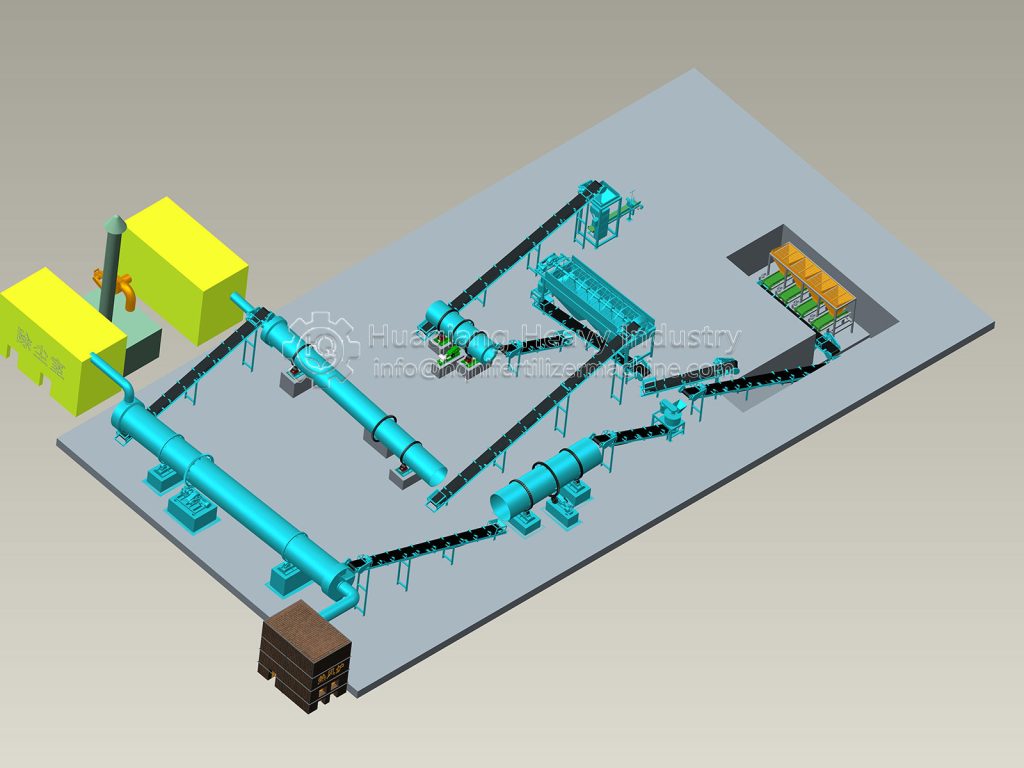

Technological innovation in NPK fertilizer production line equipment is driving industry development

In the fertilizer production industry, technological innovation in NPK fertilizer production line equipment is driving the industry’s development at an unprecedented pace, continuously improving production efficiency and product quality.

Early NPK fertilizer production equipment was relatively simple, resulting in low production efficiency and difficulty in ensuring product quality. Today, with the rapid advancement of technology, a range of advanced technologies have been applied to production line equipment.

Technological innovation in hybrid equipment is particularly important. The emergence of intelligent batching systems has enabled more precise batching of various raw materials. Using sensors to monitor the flow and weight of raw materials in real time, the control system can precisely adjust the feed rate to ensure that the mixing ratio error is kept within a very small range. Furthermore, new mixing structure designs, such as double axis mixers, can achieve uniform mixing of materials in all directions in a shorter time.

Granulation technology has also achieved significant breakthroughs. Some advanced granulation equipment uses spray drying granulation technology to produce fertilizers with uniform granules and excellent solubility. This technology not only improves fertilizer quality but also meets the needs of different crops and fertilization methods. Furthermore, the automation level of granulation equipment continues to improve, allowing it to automatically adjust granule size, shape, and strength according to set parameters. Energy-saving hot air furnaces and efficient cooling systems are widely used in drying and cooling equipment. These furnaces utilize advanced combustion technology, improving energy efficiency and reducing exhaust emissions. The efficient cooling system quickly cools fertilizer granules to the appropriate temperature, ensuring stable physical properties.

NPK fertilizer production lines have achieved a significant leap in automation control. PLC control systems allow operators to centrally monitor and operate the entire production line from a central control room. The equipment automatically detects faults and issues timely alarms, significantly improving production safety and reliability.

Furthermore, with increasingly stringent environmental protection requirements, NPK fertilizer production lines are continuously innovating in environmental protection technologies. For example, the use of efficient dust removal equipment and exhaust gas treatment systems reduces dust and exhaust emissions during the production process, achieving green production.