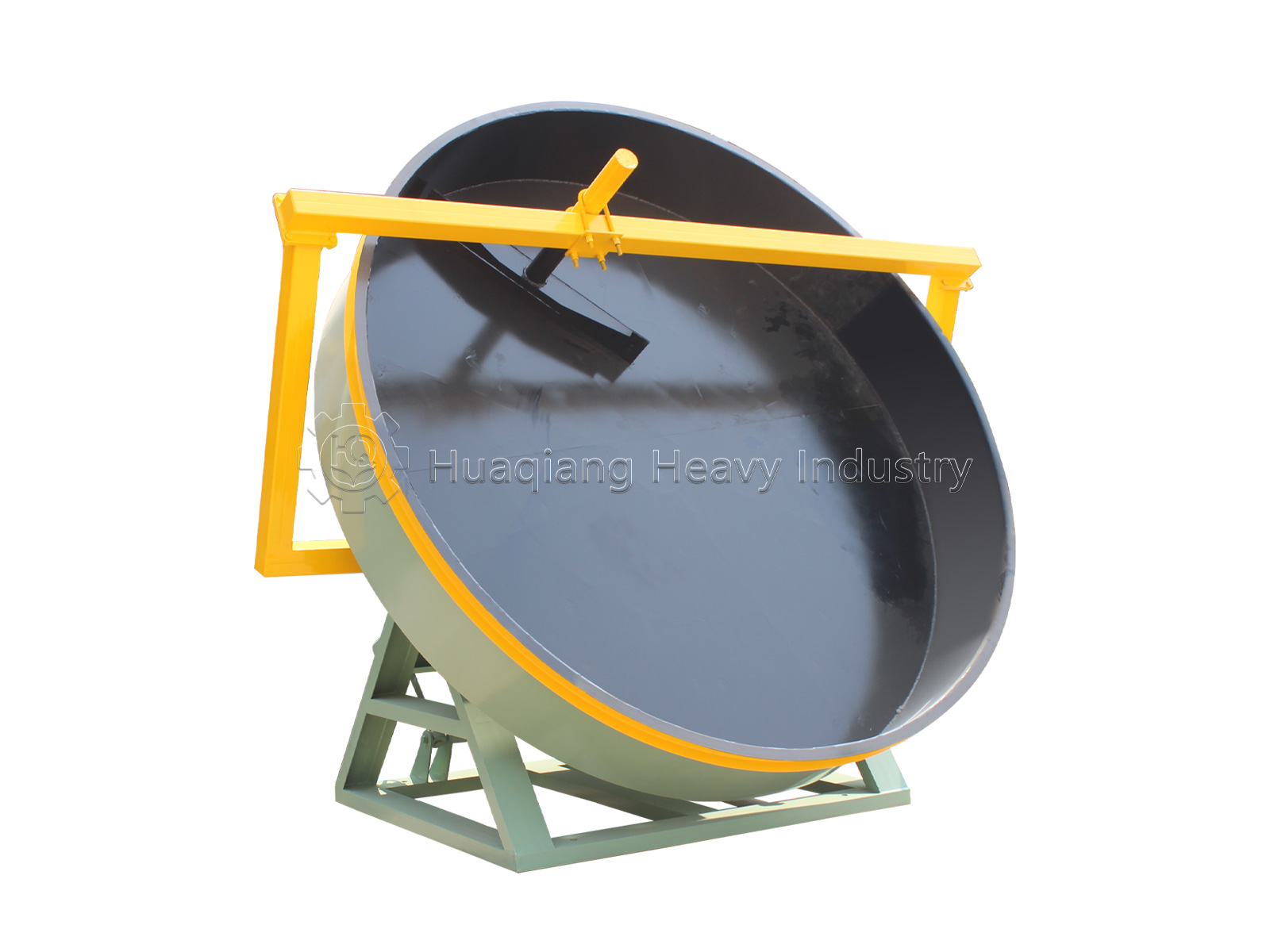

Disc granulators are a powerful granulation tool for diverse applications

As a highly efficient granulation machine, disc granulators have broad and important applications across multiple industries thanks to their simple structure, convenient operation, and excellent granulation results.

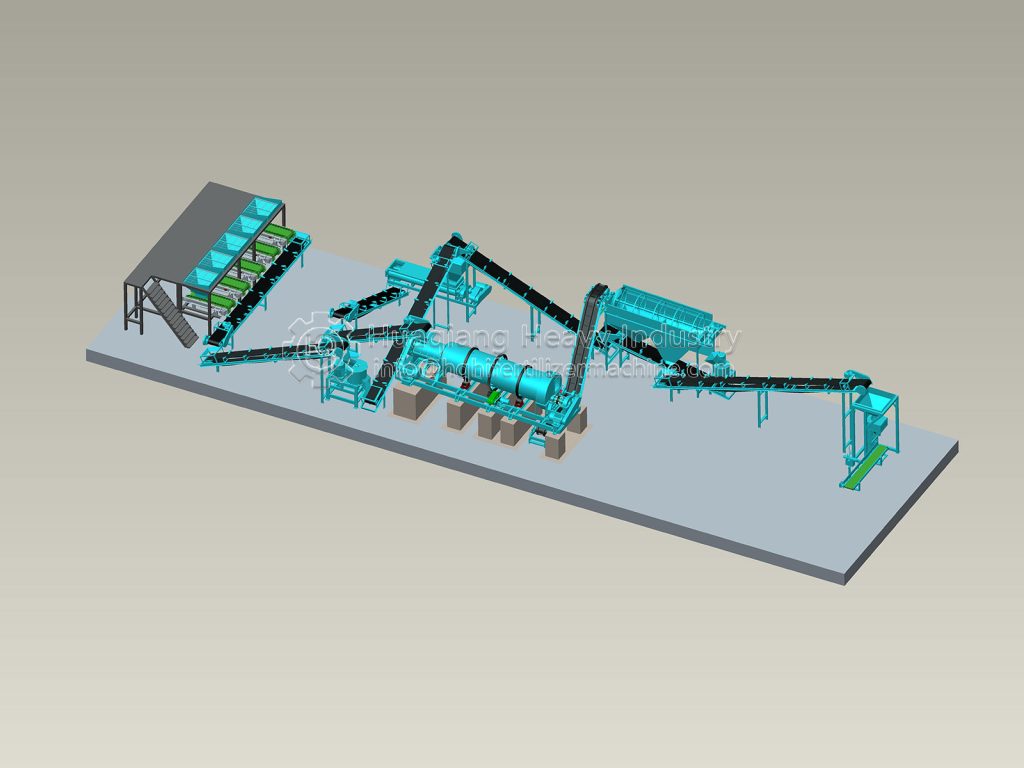

In fertilizer production, disc granulators are essential key equipment. They play a vital role in the production of compound fertilizers, organic fertilizers, and slow-release fertilizers. In compound fertilizer production lines, disc granulators mix various basic fertilizer ingredients in appropriate proportions. The rotating motion of the discs gradually forms uniform granules under the influence of centrifugal force and gravity. The resulting granulated fertilizer is not only easy to store and transport, but also improves fertilizer utilization and reduces nutrient loss. In organic fertilizer production lines, disc granulators ferment organic materials such as livestock and poultry manure and straw before granulating them. This converts loose organic materials into granulated organic fertilizer, improving its physical properties and making it easier for farmers to use. This also promotes the resource utilization of agricultural waste.

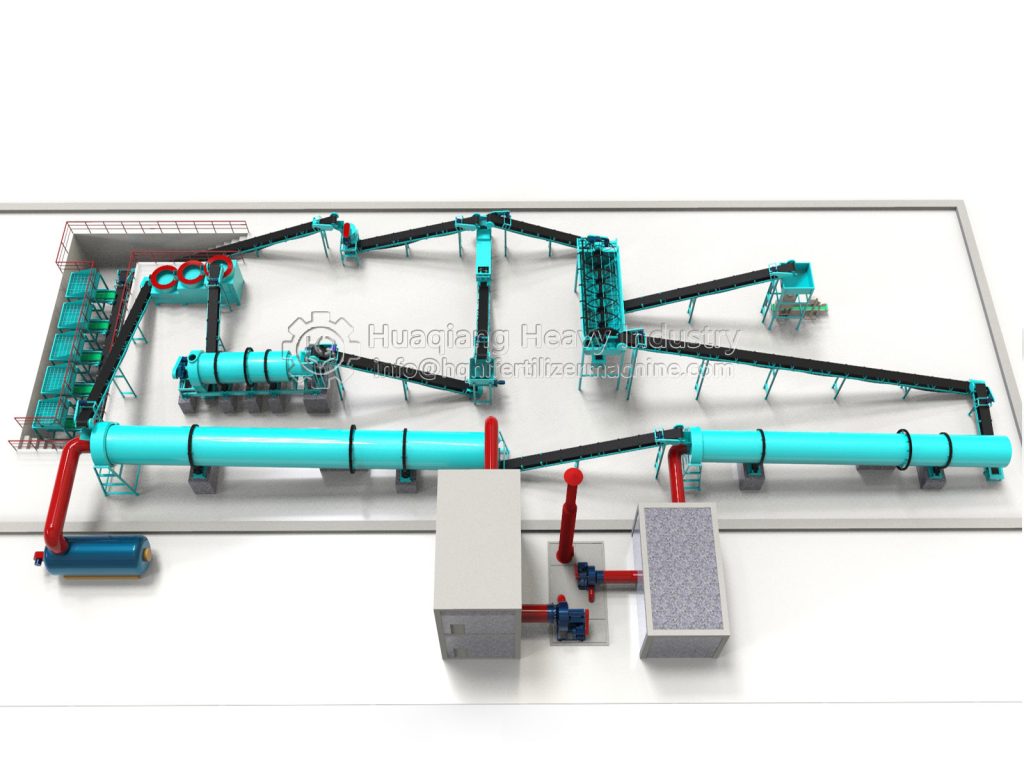

The metallurgical industry is also a key application for disc granulators. In the processing of metal ore powder, granulation is often necessary to improve smelting efficiency and utilization. Disc granulators can granulate metal ore powders such as iron ore and manganese ore. The resulting granules are characterized by high strength and good air permeability. Once introduced into smelting equipment such as blast furnaces, they facilitate a more complete smelting reaction, laying the foundation for efficient production in metallurgical enterprises.

In the environmental protection field, disc granulators have demonstrated significant application value in solid waste treatment. Granulating solid wastes such as sludge generated by municipal sewage treatment plants and slag discharged from industrial production using disc granulators not only reduces the volume of solid waste, facilitating subsequent landfill, incineration, or resource recovery, but also reduces the risk of environmental pollution.

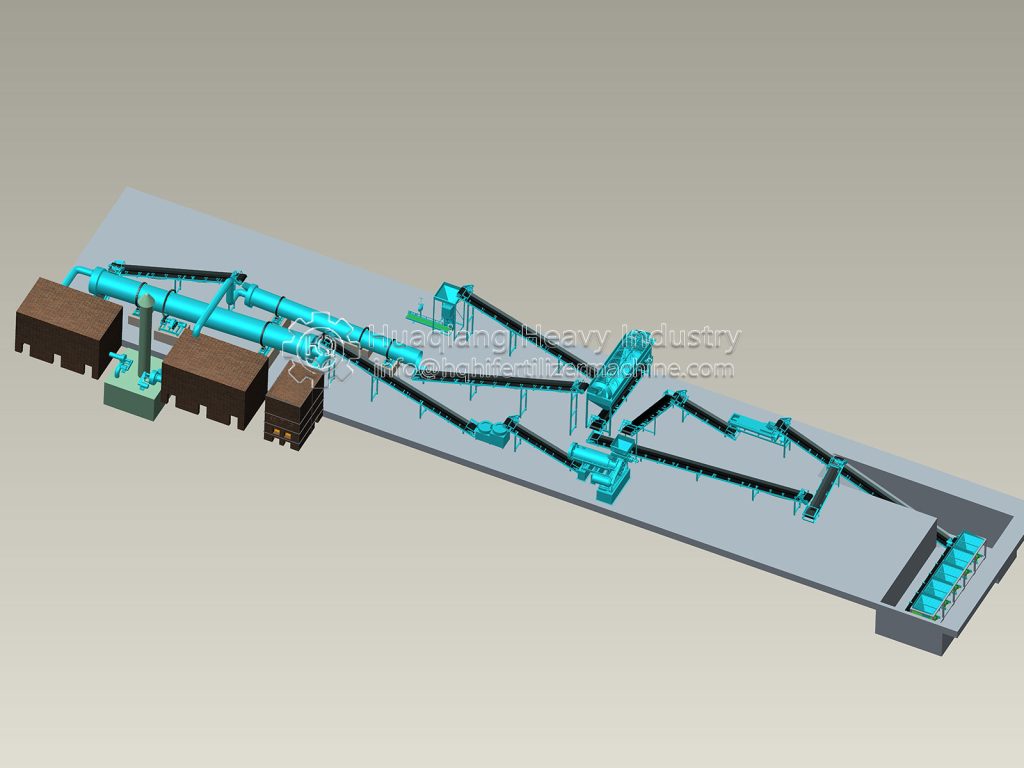

Due to its flexible applicability, disc granulators continue to play an important role in various application scenarios. As production requirements continue to increase across various industries, their application prospects will continue to expand.