Large scale organic fertilizer production equipment processing cow manure organic fertilizer

Cow manure, as a high-quality organic fertilizer raw material, has broad application prospects. For the treatment of 10000 cow manure, it is necessary to use large-scale organic fertilizer production equipment to improve production efficiency and product quality.

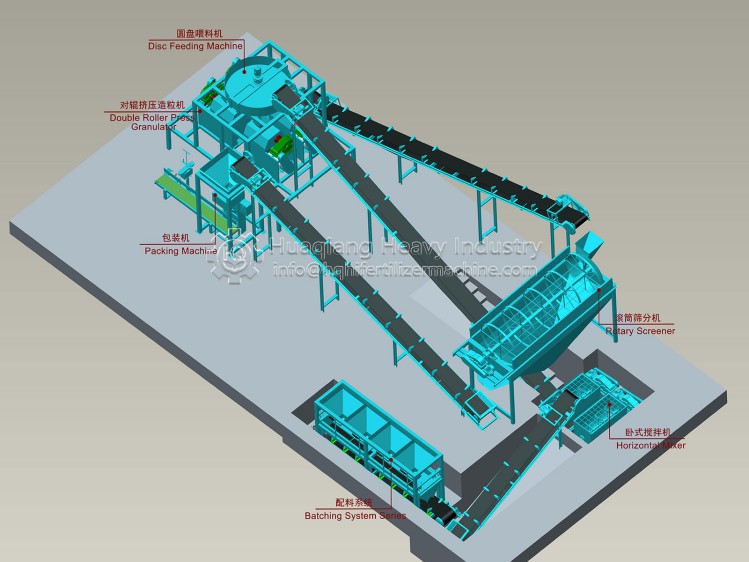

There are various types of equipment for producing organic fertilizers, mainly including fermentation equipment, drying equipment, crushing equipment, screening equipment, and packaging equipment..jpg)

Organic fertilizer fermentation equipment is the core equipment for producing organic fertilizers, which converts organic matter in cow manure into stable humus through aerobic or anaerobic fermentation methods. The organic fertilizer drying equipment is used to reduce the moisture content of the fertilizer for subsequent treatment. The organic fertilizer crushing equipment and screening equipment are respectively used to crush the raw materials into appropriate particle sizes and screen out unqualified particles. Finally, the organic fertilizer packaging equipment packages the finished organic fertilizer for easy storage and transportation.

The required equipment output for the treatment of 10000 cow manure needs to be calculated based on specific production cycles, raw material moisture content, and other factors. Generally speaking, the annual output of large-scale organic fertilizer production equipment ranges from tens of thousands to hundreds of thousands of tons. When selecting equipment, factors such as equipment capacity, raw material processing capacity, floor area, and energy consumption need to be considered. Meanwhile, the selection and maintenance costs of equipment also need to be taken into consideration.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)