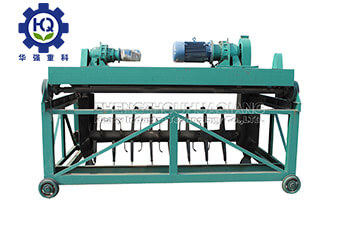

1. Organic fertilizer continuous trough dumper (single machine), models are 4m, 6m, 8m, 10m. The fermentation cycle is 7-8 days, the daily processing capacity is 800-1000 cubic meters, and the annual production capacity is 10000-20000 tons. Multi tank fermentation can increase production by 20000-50000 tons, and organic fertilizer can be fully fermented, which is suitable for granulation by rotary drum granulator.

2. Feeding at the feeding port and blanking at the other end. Daily feeding, daily blanking, daily processing. When the transfer section needs to be replaced after the transfer, the mixing shaft can be raised to quickly run the equipment to the transfer section.

3. The innovation of compost turning machine is to make full use of the deep pool design of underground space and the new technology of long-distance pile turning, so as to realize the large-scale harmless treatment of organic waste with limited surface area.

4. The composting dumper is compact in structure and advanced in technology. Some beneficial microorganisms are used to promote the rapid decomposition of organic wastes such as livestock manure. The unique tank type continuous aerobic fermentation technology is used to decompose, dehydrate, sterilize and deodorize organic waste rapidly, so as to achieve the goal of harmless and resource-based treatment. The decomposed organic fertilizer is processed by fertilizer granulator.

5. Intelligent automatic control of the fermentation material turning process. Under the action of the vertical and horizontal walking mechanism, the fermented material produces a certain pile-turning displacement in the tank, and returns to the tank regularly at equal distances, continuously and gradually, forming a continuous aerobic fermentation process. The stirring knife not only rotates evenly and oxidizes, but also has the function of crushing materials.

6. The electronic control system of the equipment is advanced and reliable, easy to operate, with manual and remote control. After the host starts to run, turn the rotary button to the “automatic” state, turn on the walk button, the flip machine starts to work, and the entire machine equipment runs longitudinally.