The configuration of the organic fertilizer production line is high or low. The configuration of the organic fertilizer production line with an annual output of 50000 tons is roughly as follows:

Step 1: organic fertilizer fermentation

The fermentation of organic fertilizer collects the excrement, mixes with hay and rotten silage to make compost and ferment it. In the process of fermentation, the compost windrow turner is used to fully ferment the feces and make aerobic composting. It is a method to make the organic fertilizer stable, harmless and then turn into high-quality fertilizer by using the compost windrow turner and fermentation bacteria under aerobic conditions

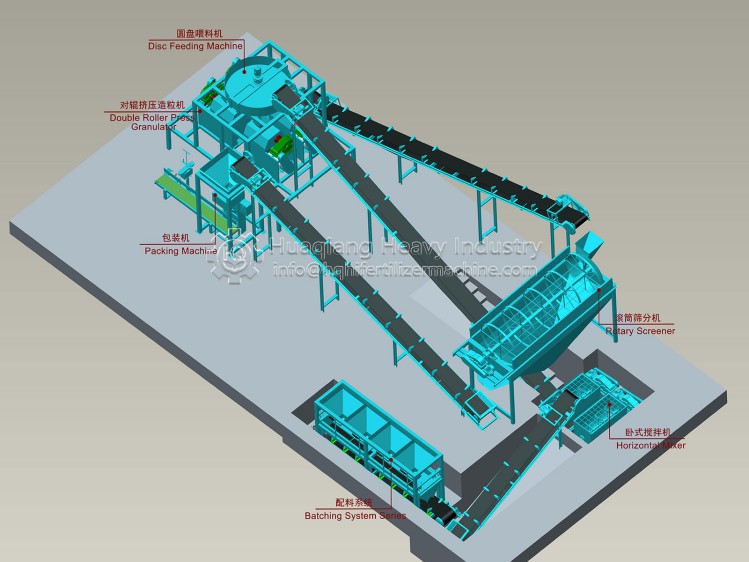

Step 2: crushing and mixing of ingredients

The composted materials, such as N, P, K and other inorganic fertilizers, and other additives are crushed, proportioned and mixed in a certain proportion through the material grinder and horizontal mixer by using the batching bin.

Step 3: Granulation

A new type of organic fertilizer granulator is used to granulate materials.

Step 4: screening and return system

There is a certain difference in the particle size of the particles output from the pelletizing and molding system, which requires screening and grading. The selected roller screen is used to screen the particles.

The investment price of organic fertilizer production equipment can be more or less. If we want to produce powdered organic fertilizer processing, we only need to invest in one fermentation equipment, crusher and screening machine. The investment is 60000 yuan. If we want to produce granular organic fertilizer, we need to add organic fertilizer granulator, dryer, annual output of 10000 tons of organic fertilizer generally do not need cooling machine. About 200000 yuan has been invested. The plant site can be large or small. Generally, the total site needs 3 to 5 mu of land.