The pig manure organic fertilizer equipment is suitable for the production of organic fertilizer production lines in breeding enterprises or large breeding areas. It can effectively reduce the pollution discharge of pig farms, realize the harmless treatment of breeding pollution, and achieve the purpose of resource utilization. Pig manure organic fertilizer equipment adapts to the strategy of commercialization of organic fertilizers, and promotes the formation of the production industry chain.

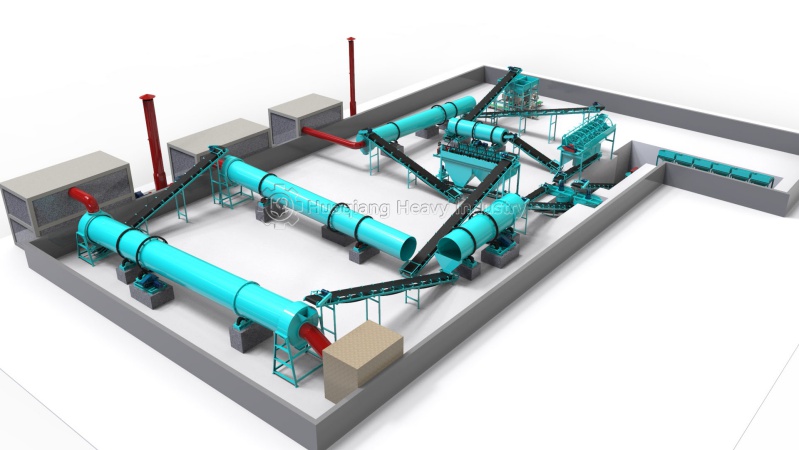

The general production process of organic fertilizer includes: organic material inoculation fermentation (pre-fermentation), main fermentation, crushing, compounding and mixing, drying, granulation, cooling, screening, measurement and packaging and other processes. The main equipment of the organic fertilizer equipment processing technology is fermentation tank, mixer, overturning equipment, belt conveying equipment, cylindrical screen, pulverizer, granulator and so on.

1. Forklift feeding bin: to ensure uninterrupted feeding of production

2. Stirring: It is mainly used for mixing raw materials and auxiliary materials to make the distribution of organic matter more uniform.

3. Granulation: the most common are the npk fertilizer granulator, disc granulator machine, tooth stirring granulator, drum granulator, the granules produced by each granulator are different, and the applicable materials are Inevitable requirements, the variety of granulator can be determined according to the selection of raw materials.

4. Drying and cooling: The equipment is in a cylindrical rotary type, the dryer dries the excess water in the pellets, and the cooler cools the pellets in time to facilitate and quickly enter the next process.

5. Screening: the most common are trommel screening machine and vibrating screening machine, and the qualified particles are retained and transported to the next separation process through belt conveyor.

6. Automatic packaging machine: automatically pack into bags according to the set weight