Sheep themselves are herbivores and are sensitive to chemical components, so there are very few pollutants in their bodies. Organic fertilizers used in the planting industry are very effective in improving the land. So what equipment is needed to raise 5000 sheep and produce organic fertilizer from sheep manure?

Sheep manure is rapidly fermented into organic fertilizer using traditional fermentation methods, which have low investment costs. However, if the fermentation time is too long, there may also be problems with incomplete fermentation. To quickly ferment sheep manure into organic fertilizer, it is necessary to use organic fertilizer production equipment for processing.

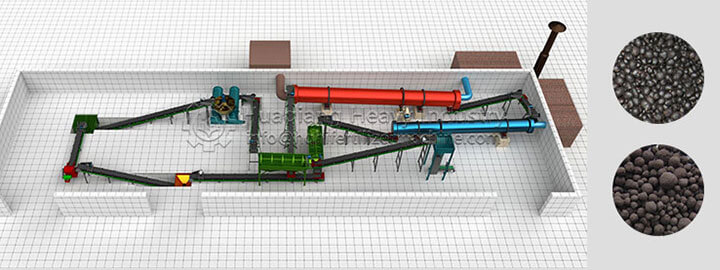

The complete set of sheep manure organic fertilizer processing supporting equipment includes: flipper, crusher, mixer, organic fertilizer granulator, dryer, cooling machine, screening machine, coating machine, and weighing and packaging machine. The total investment price of the complete equipment is higher than the investment amount of the simple equipment production line

The equipment composition of the sheep manure organic fertilizer production line is similar to that of the pig manure organic fertilizer production line, except for the granulation equipment. Because the fiber of sheep manure is thicker, using a disc granulator to granulate will reduce the success rate of granulation and lower the output of the entire production line. Therefore, the sheep manure organic fertilizer production line needs to be equipped with a new type of stirring tooth granulator, so that the finished particles produced are flat and round. Fertilizer factories with high requirements for product quality need to add a rounding machine to improve the roundness of the finished particles and also enhance the competitiveness of the finished organic fertilizer in the market.