The Magical Journey from Raw Materials to Finished Products

Imagine transforming ordinary materials like urea, phosphate rock powder, and potash into uniform, perfect fertilizer pellets – this process resembles a carefully choreographed industrial ballet. Modern NPK fertilizer production lines achieve this transformation through a series of precisely designed processes. Let’s unveil the mystery behind this production method.

Raw Material Preparation: The Starting Point of Perfect Formulation

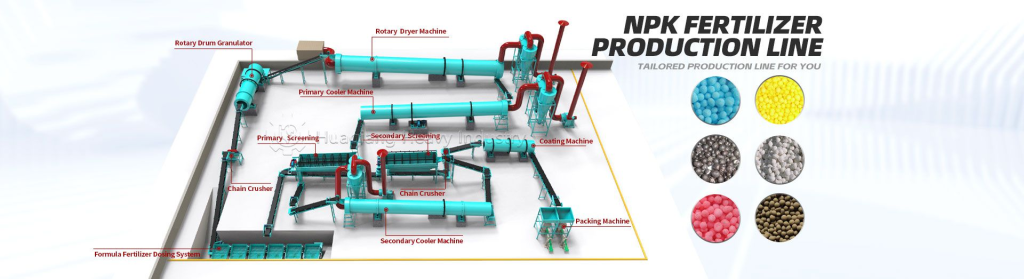

Everything begins with precise material ratios. Just as baking requires accurate measurement of ingredients, NPK fertilizer production starts by precisely weighing nitrogen (N), phosphorus (P), and potassium (K) materials according to the target formula. Subsequently, large chunks of raw materials are crushed into fine particles suitable for mixing by chain crushers, preparing them for subsequent processes.

Mixing and Granulation: The Art of Creating Uniform Pellets

When various materials dance in dual-shaft paddle mixers or V-type mixers, a feast of uniform blending begins. An appropriate amount of water is then added according to granulation needs, bringing the mixture to ideal humidity. At this point, equipment like disc granulators, rotary drum granulators, or extrusion granulators take the stage, shaping these mixtures into pellets of specific sizes and forms through rotation or pressure.

Drying and Cooling: Critical Steps for Stable Pellets

Newly formed wet pellets need “sauna” treatment in dryers, where fluidized bed dryers or rotary drum dryers remove moisture with hot air. Immediately after, the hot pellets “cool down” in cooling drums, reaching suitable temperatures to ensure stable fertilizer performance.

Screening and Packaging: The Final Checkpoints for Quality Control

Vibrating screens act like strict quality inspectors, only allowing pellets that meet size requirements to pass. Oversized pellets need “reprocessing,” while undersized ones may be recycled as dust. Some production lines even dress qualified pellets in “protective clothing” – coating machines apply organic or inorganic films to the pellet surfaces. Finally, automatic packaging machines dress these perfect pellets in neat “outfits,” ready for their journey.

Intelligent Control: The Nerve Center of the Production Line

The entire NPK fertilizer production line is conducted by advanced PLC control systems, like a tireless conductor, precisely monitoring and adjusting key parameters such as material ratios, granulation humidity, and drying temperature to ensure process stability and product consistency.